A positioning pressing support device

A technology of supporting device and clamping mechanism, which is applied in the directions of transportation and packaging, space navigation equipment, space navigation equipment, etc., to achieve the effect of good unfolding stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

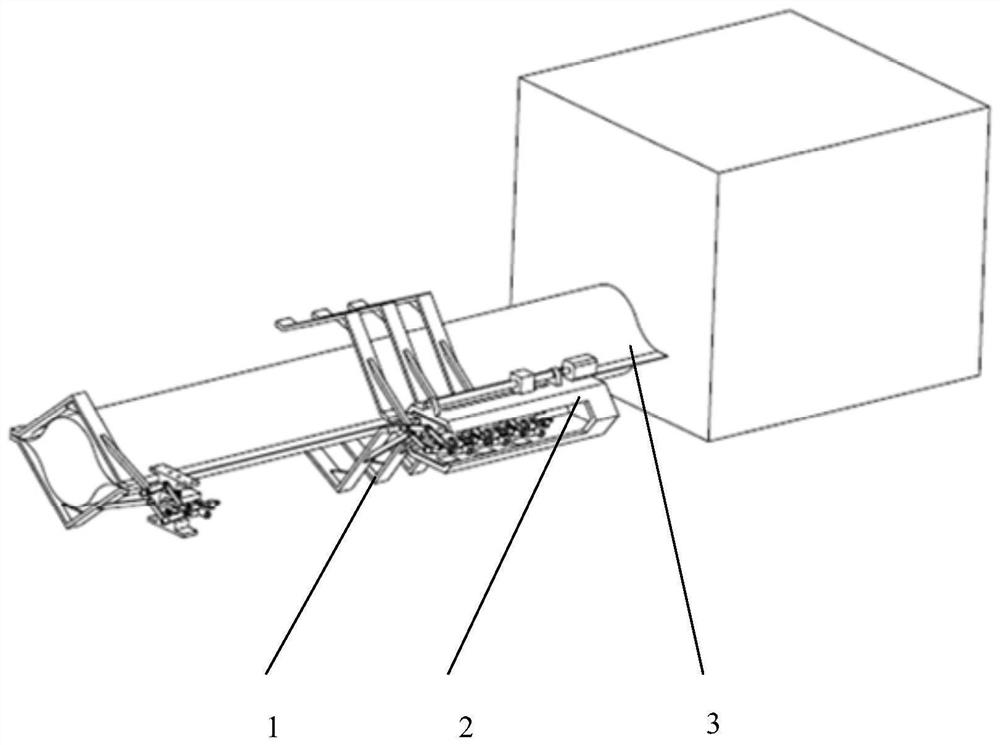

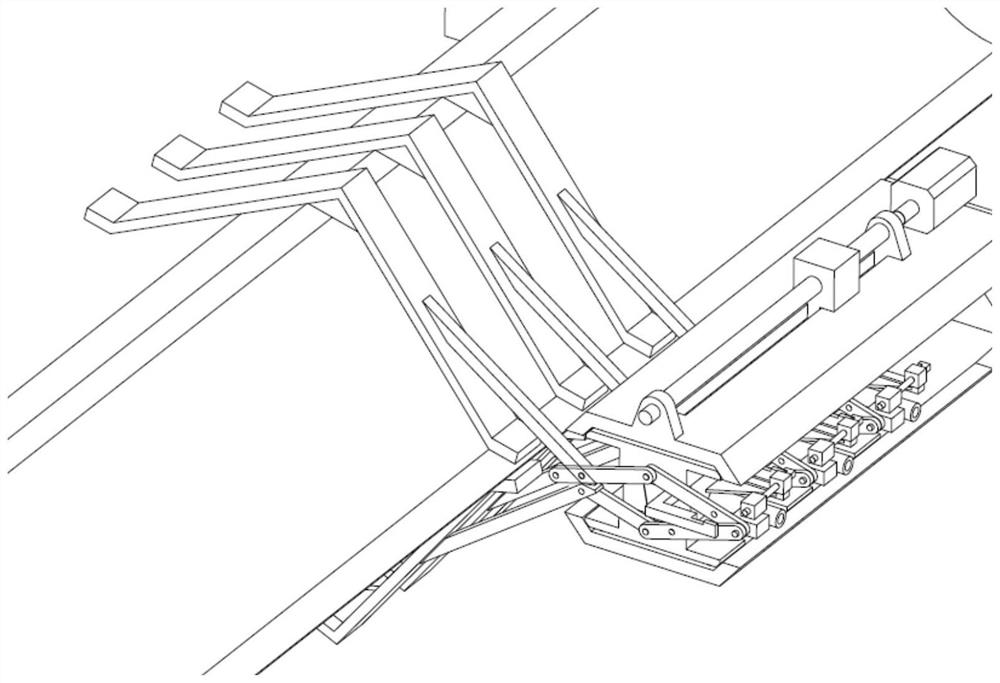

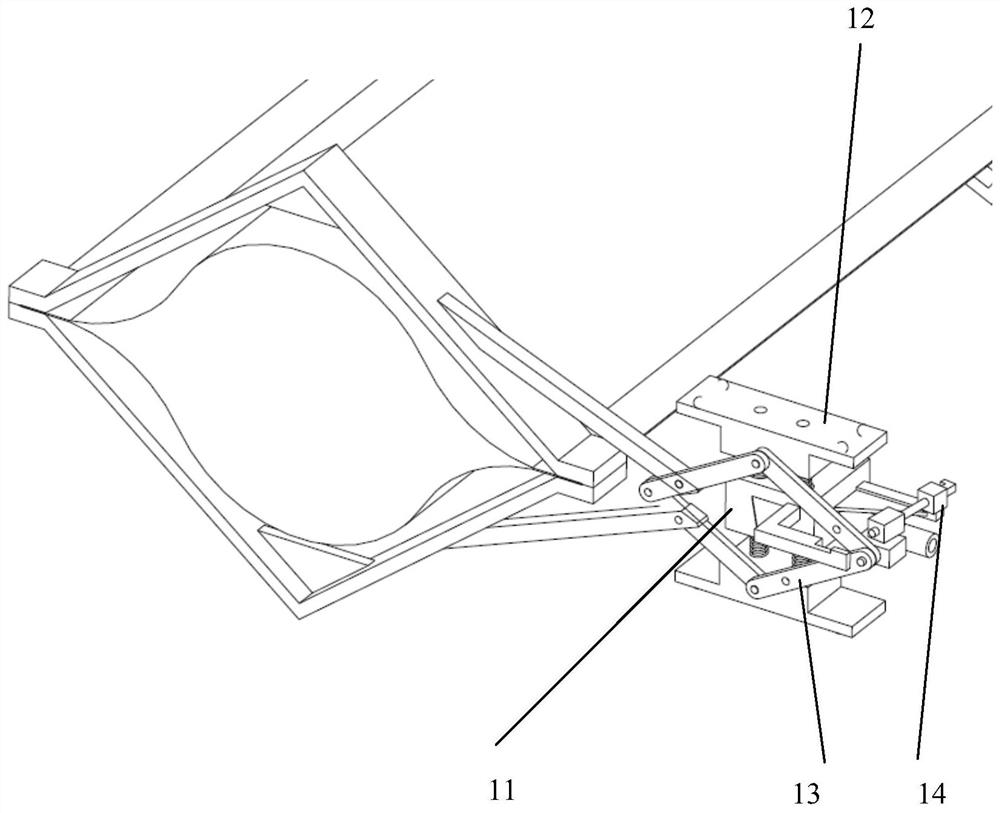

[0029] Such as Figure 1 to Figure 12 As shown, a positioning and pressing support device includes a clamping mechanism 1 and a driving and guiding mechanism 2 . The clamping mechanism 1 is a mechanism for clamping and connecting the extension part 3 , which can slide on the guide rail 21 of the driving and guiding mechanism 2 and is constrained by the shape of the guide rail 21 . The driving and guiding mechanism 2 can drive the position of the clamping mechanism 1 on the guide rail 21 .

[0030] The clamping mechanism 1 is located inside the guide rail 21 of the driving and guiding mechanism 2, and the clamping mechanism 1 and the guide rail 21 are in a relative moving relationship; the stretching part 3 can stretch and move in the clamping mechanism 1 in the unclamped state during the stretching process. Constituting stretching movement constraints, the clamping mechanism 1 in the clamped state forms a clamping connection with the stretching part 3 .

[0031] The clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com