Auxiliary fixture used in busbar processing

A technology for auxiliary fixtures and busbars, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of ensuring processing quality, simple structure, and widely popularized value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

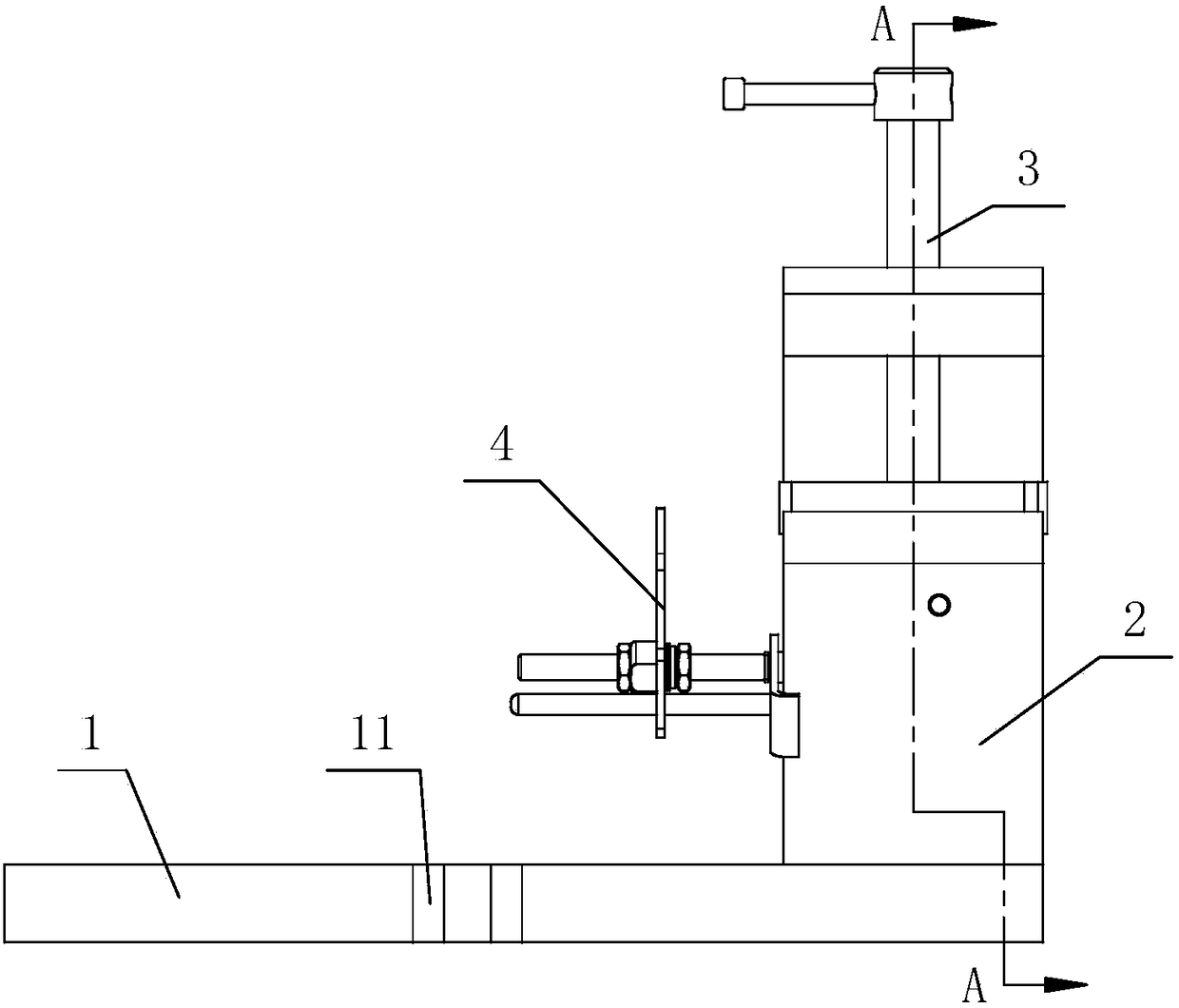

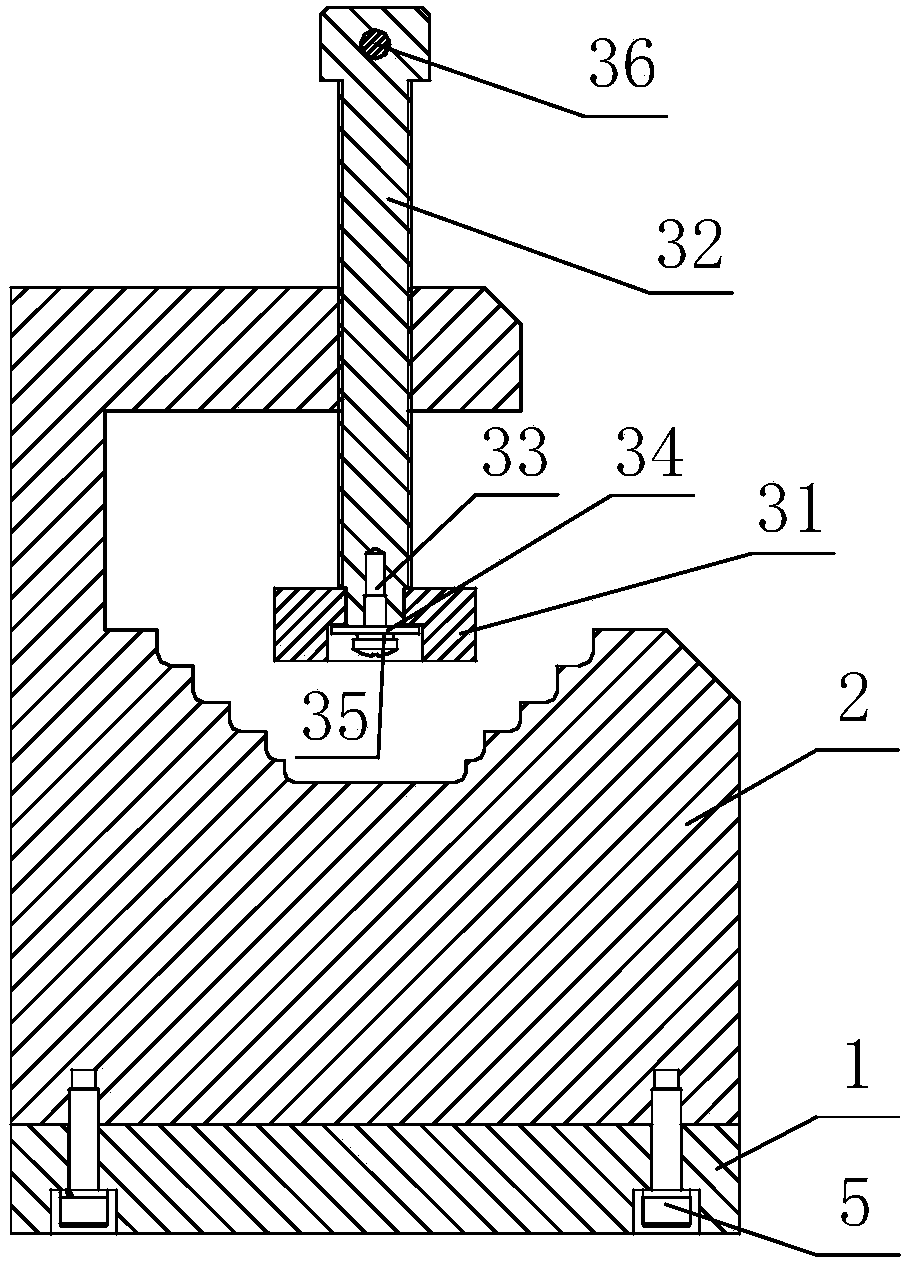

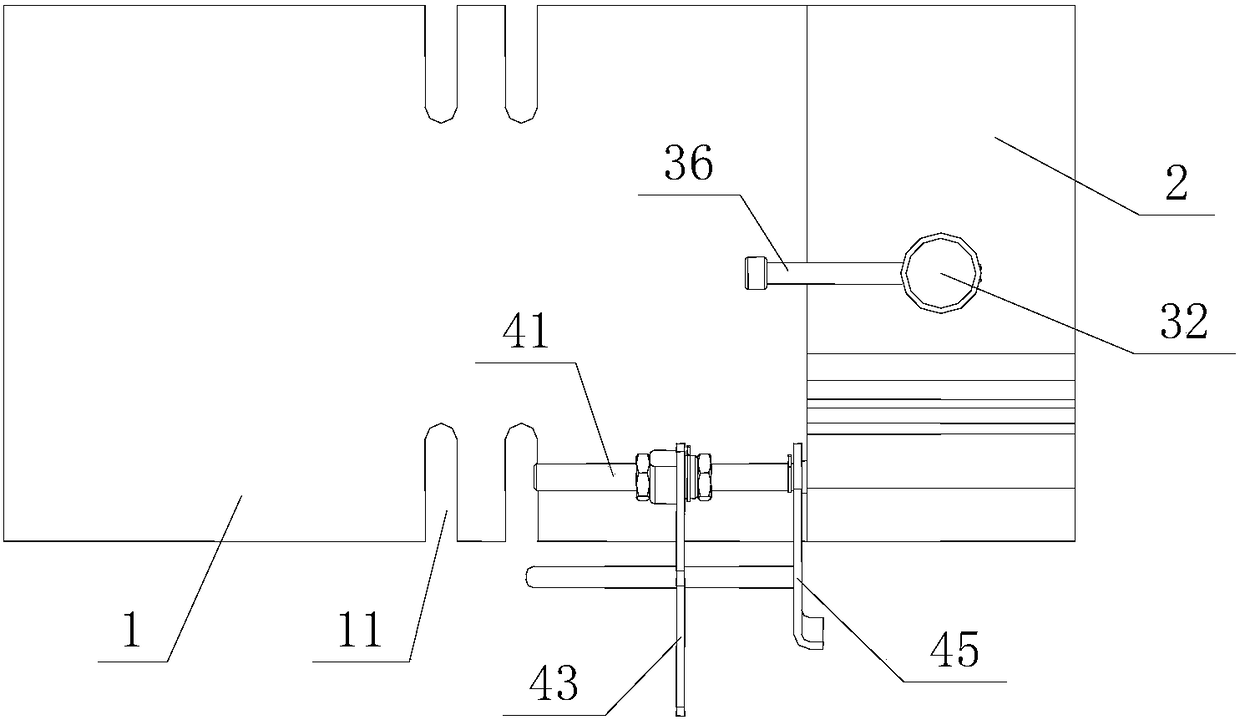

[0028] Such as Figure 1 to Figure 8 As shown, an auxiliary fixture used in busbar processing includes a base 1 , a base 2 and a clamping mechanism 3 . The base 1 is the base body of the entire auxiliary fixture of the present invention, and is used to carry each link of the auxiliary fixture. The base 1 is a rectangular plate structure, such as figure 1 and image 3 As shown, four installation notches 11 penetrating the upper and lower surfaces are respectively opened on the opposite long side edges of the base 1. When processing the busbar, the base 1 is fixed through the four installation notches 11 by bolts. on the table top of the processing equipment.

[0029] The lower surface of the base 1 is provided with a countersunk through hole penetrating its upper surface, and the bottom of the base 2 is provided with a threaded hole cooperating with the countersunk through hole, and the countersunk through hole and the threaded hole are respectively There are four, and the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com