A substation construction structure built with prefabricated components

A technology of prefabricated components and prefabricated structures, applied in substation rooms, building components, building structures, etc., can solve problems such as no formation, uneven force, uneven settlement, etc., to reduce safety hazards, improve construction efficiency, The effect of not being easily deformed by force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

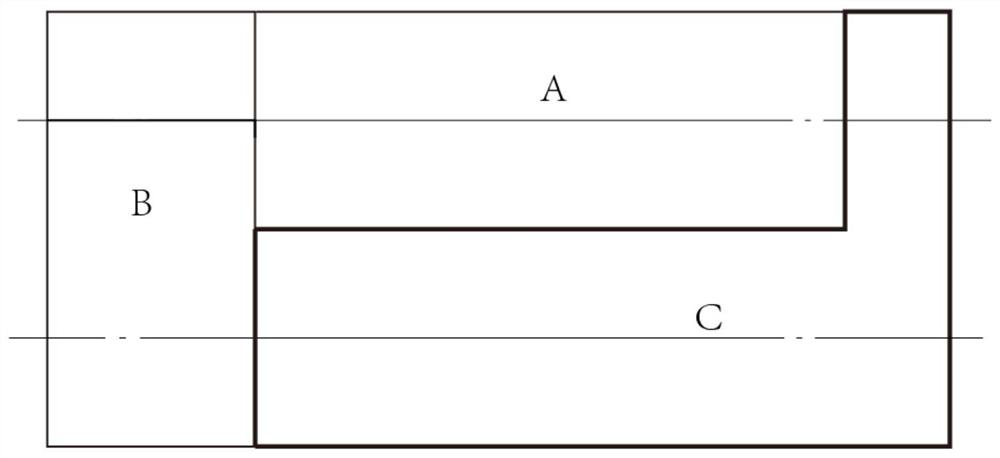

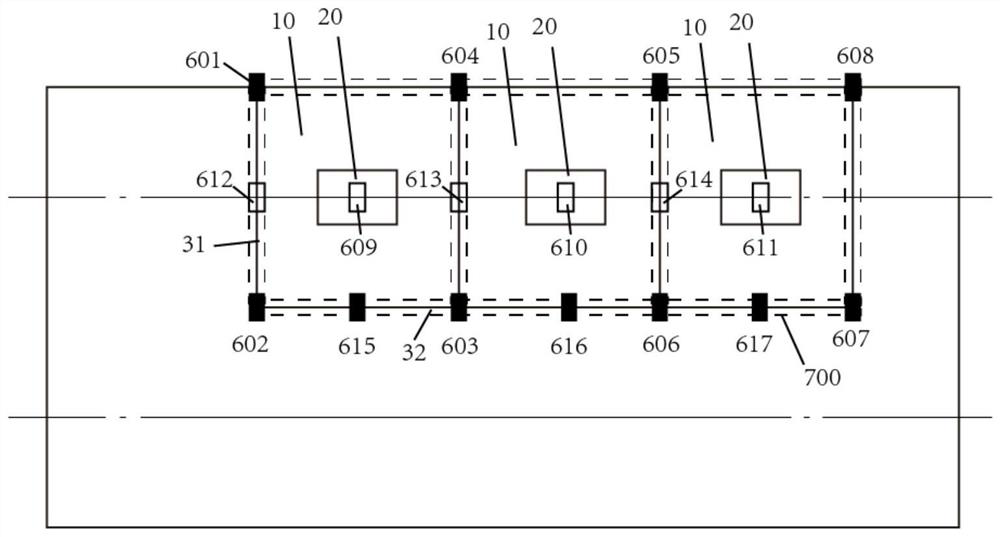

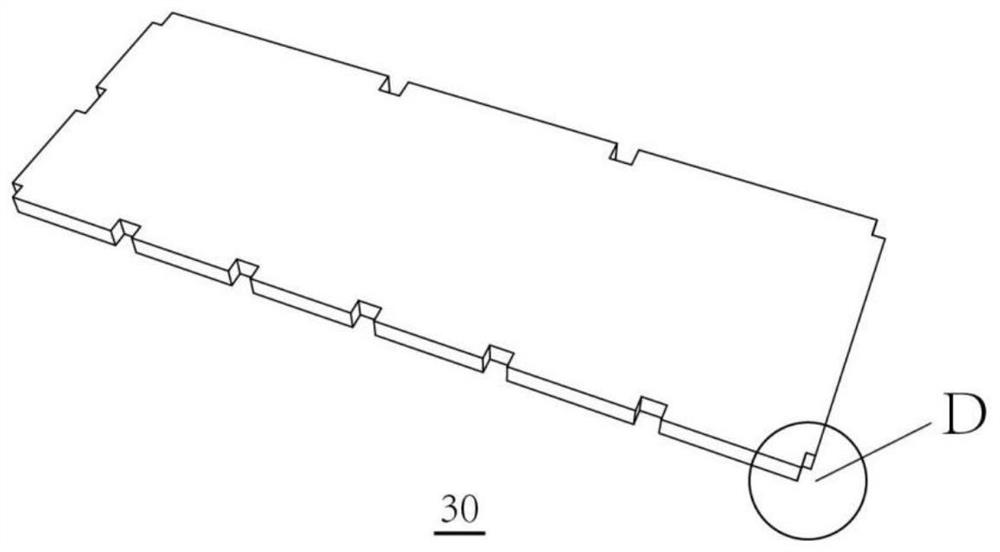

[0035] Such as figure 1 , 2 , 3, and 5, this embodiment is a substation construction structure built with prefabricated components, including the main transformer oil pit area A, the grounding substation equipment area B, and the underground wiring area C. The main transformer oil pit area A is equipped with a main The transformer foundation 10 and the main transformer oil pit foundation 20, the main transformer oil pit foundation 20 and the main transformer foundation 10 are supported by the first prefabricated bottom plate 30, and the aboveground parts of the grounding substation equipment area B and the underground wiring area C are supported by the second prefabricated bottom plate 40 , the underground wiring area C is supported by the third prefabricated floor 50, the first prefabricated floor 30 is provided with structural columns 600 at least around the periphery, and the periphery and middle of the second prefabricated floor 40 are evenly distributed with structural co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com