Fabricated four-way cable well and construction method thereof

A cable well and prefabricated technology, which is applied in the field of prefabricated four-way cable well and its construction, can solve the problems of low construction efficiency and heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

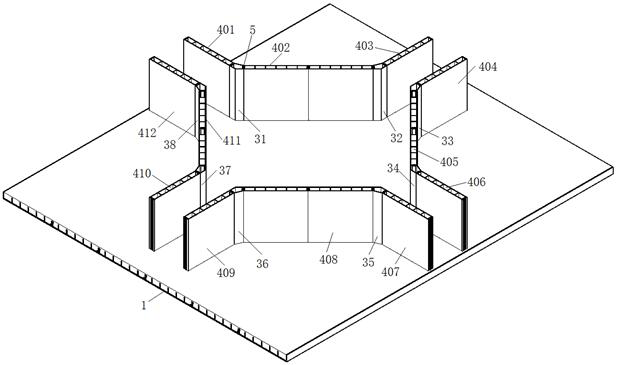

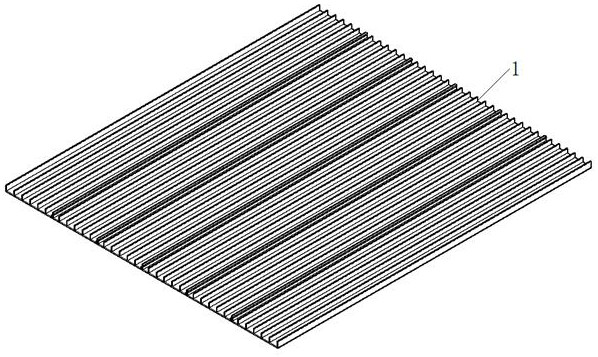

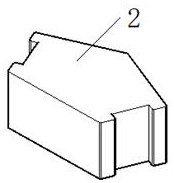

[0034] like figure 1As shown, an assembled four-way cable shaft includes a bottom plate 1, a base 2, a corner post 3, a baffle plate 4, a latch 5 and a cover plate; the corner post 3 includes a first corner post 31, a second corner post 32, and a third corner post 33 , the fourth corner post 34, the fifth corner post 35, the sixth corner post 36, the seventh corner post 37 and the eighth corner post 38; the baffle plate 4 includes a first baffle plate 401, a second baffle plate 402, a third baffle plate 403, the fourth baffle 404, the fifth baffle 405, the sixth baffle 406, the seventh baffle 407, the eighth baffle 408, the ninth baffle 409, the tenth baffle 410, the eleventh baffle 411 and the twelfth baffle plate 412; the top surface of the bottom plate 1 is provided with a fine stone concrete layer, and the bottom plate 1 and the fine stone concrete layer form a combined bottom plate; the bottom plate 1 is provided with eight bases 2, and the eight bases 2 are pressed Octa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com