Electronic module wedge-shaped packaging slot locking force measuring system

An electronic module and measurement system technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of unrealizable, inaccurate measurement, and no locking force measurement system, and achieve stress-avoiding tests. , strong nonlinear response characteristics, the effect that meets the needs of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

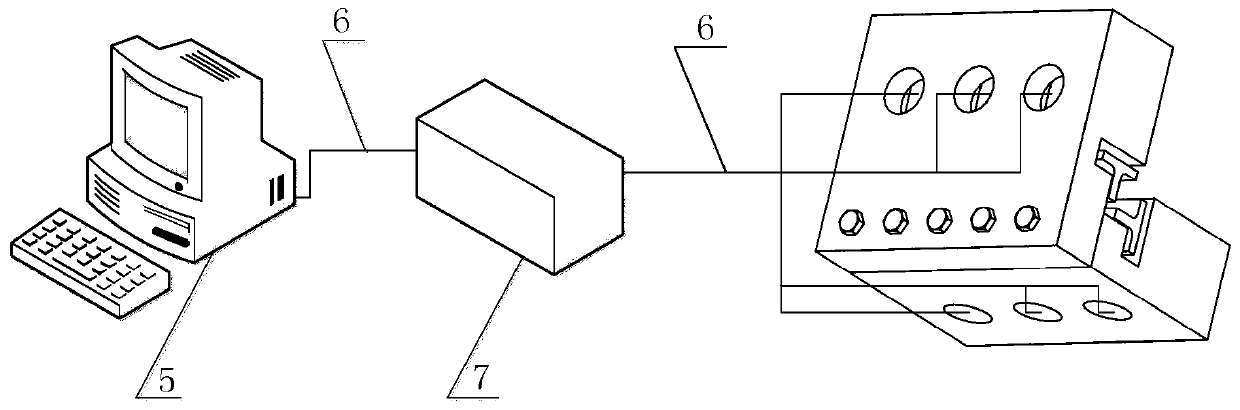

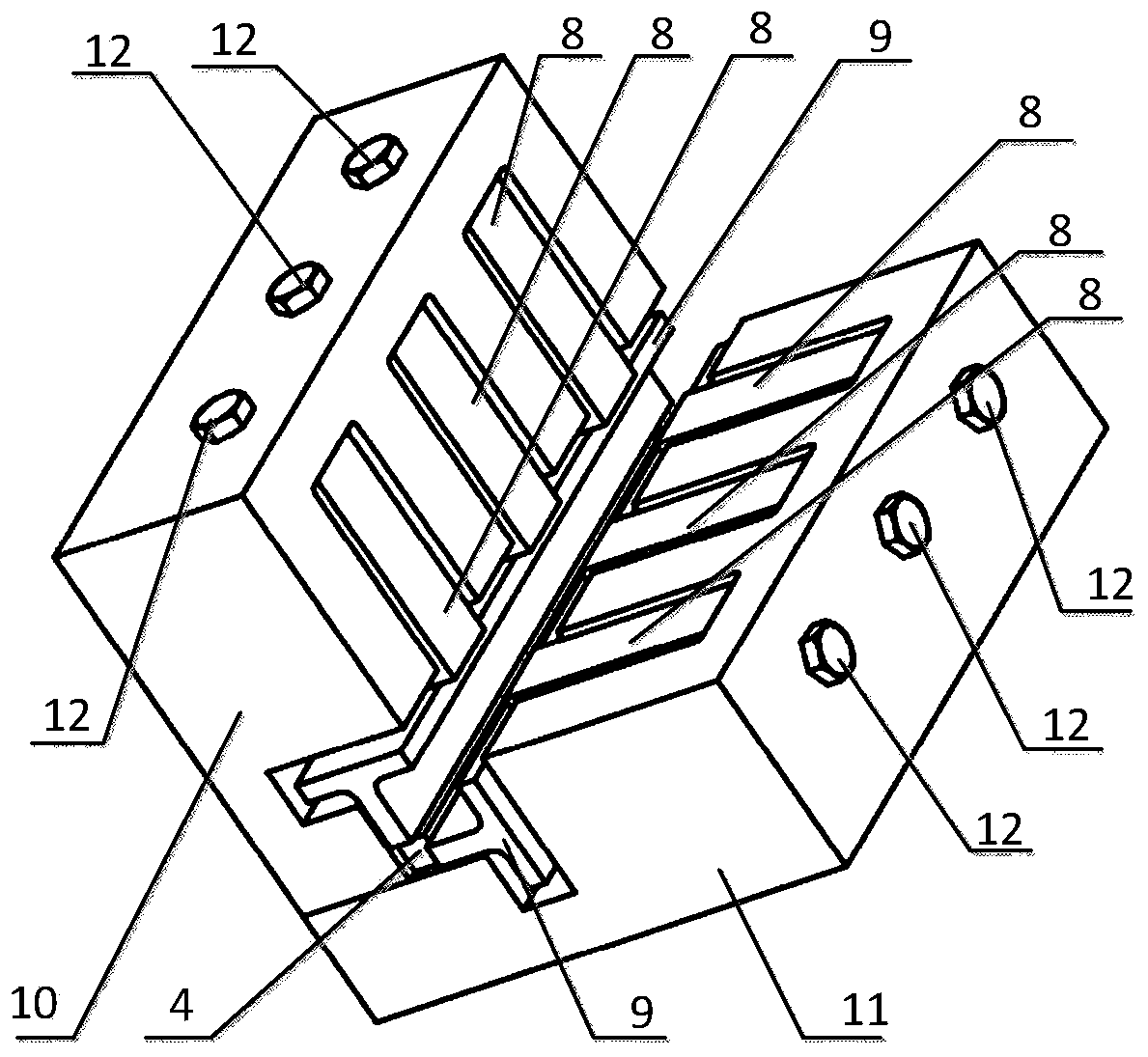

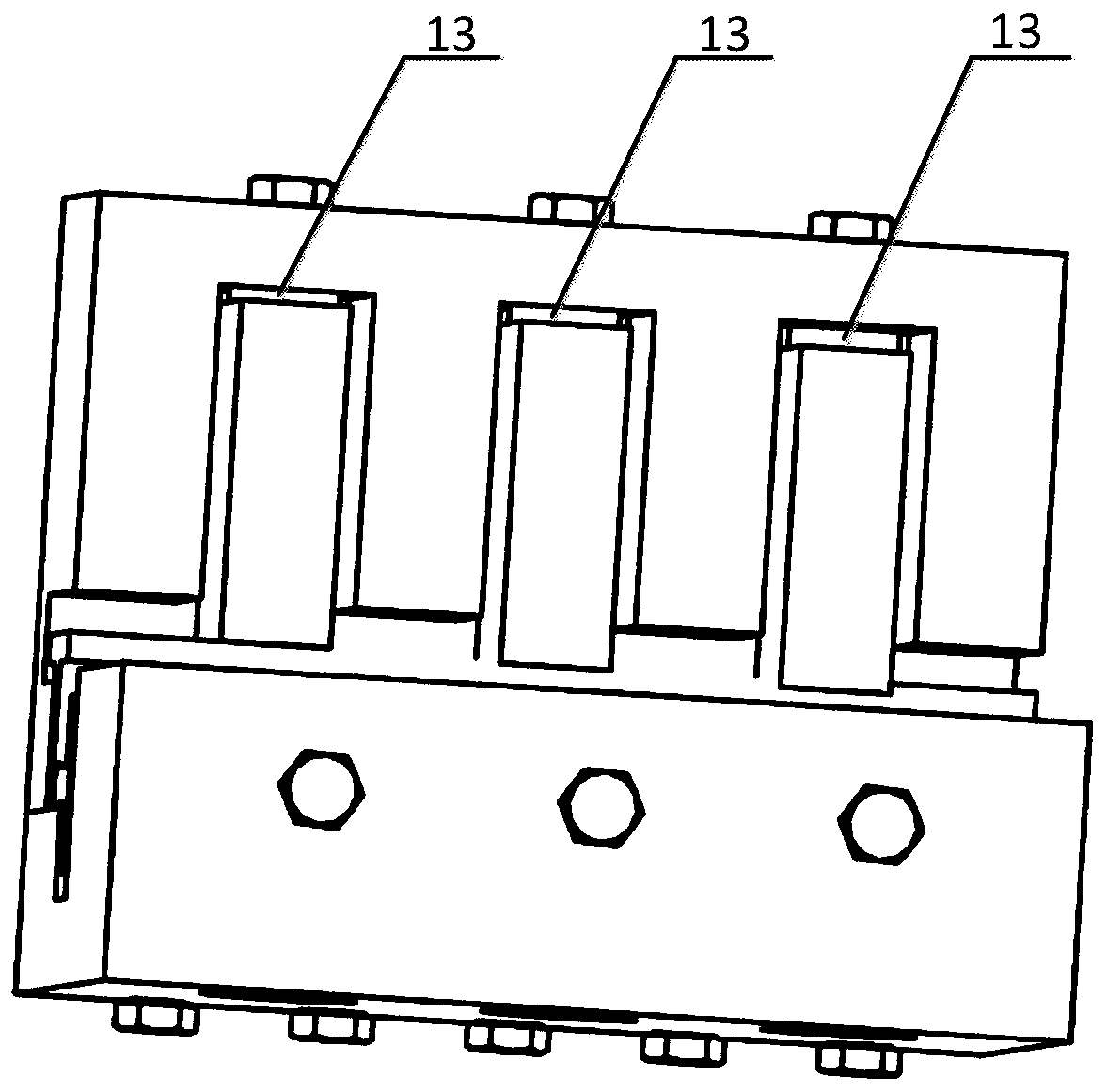

[0019] refer to Figure 1-Figure 4 . In the preferred embodiment described below, a kind of electronic module wedge packaging socket locking force measurement system includes: installed on the vibration table, impact table, connected between the host computer 5 and the test module through the data connection line 6 Data acquisition instrument 7. Among them, the test module has a rectangular short base 10 and a long base 11 which are vertically overlapped with each other, and the formed L-shaped root is formed with a low thermal conductivity locking strip 2 and a high thermal conductivity locking strip perpendicular to each other. 4, the end face of the L-shaped vertical body is also provided with positioning bolts 12 arranged in a line array and a line array groove for assembling the pressure sensor 8 on the inner side of the vertical plane, and the data connection line 6 of each pressure sensor 8 passes through the line array The wire hole at the back end of the groove is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com