Cross array type underwater explosion pressure load spatial distribution measuring device and system

A cross-array, underwater explosion technology, applied in the direction of measuring devices, force/torque/work measuring instruments, blasting force measurement, etc., can solve the problem of high cost, difficult to withstand underwater near-field pressure peak, detonation product impact and high temperature Conditions, small measurement range and other issues, to achieve the effect of ensuring safe recycling, huge measurement range and the strength of sensitive components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

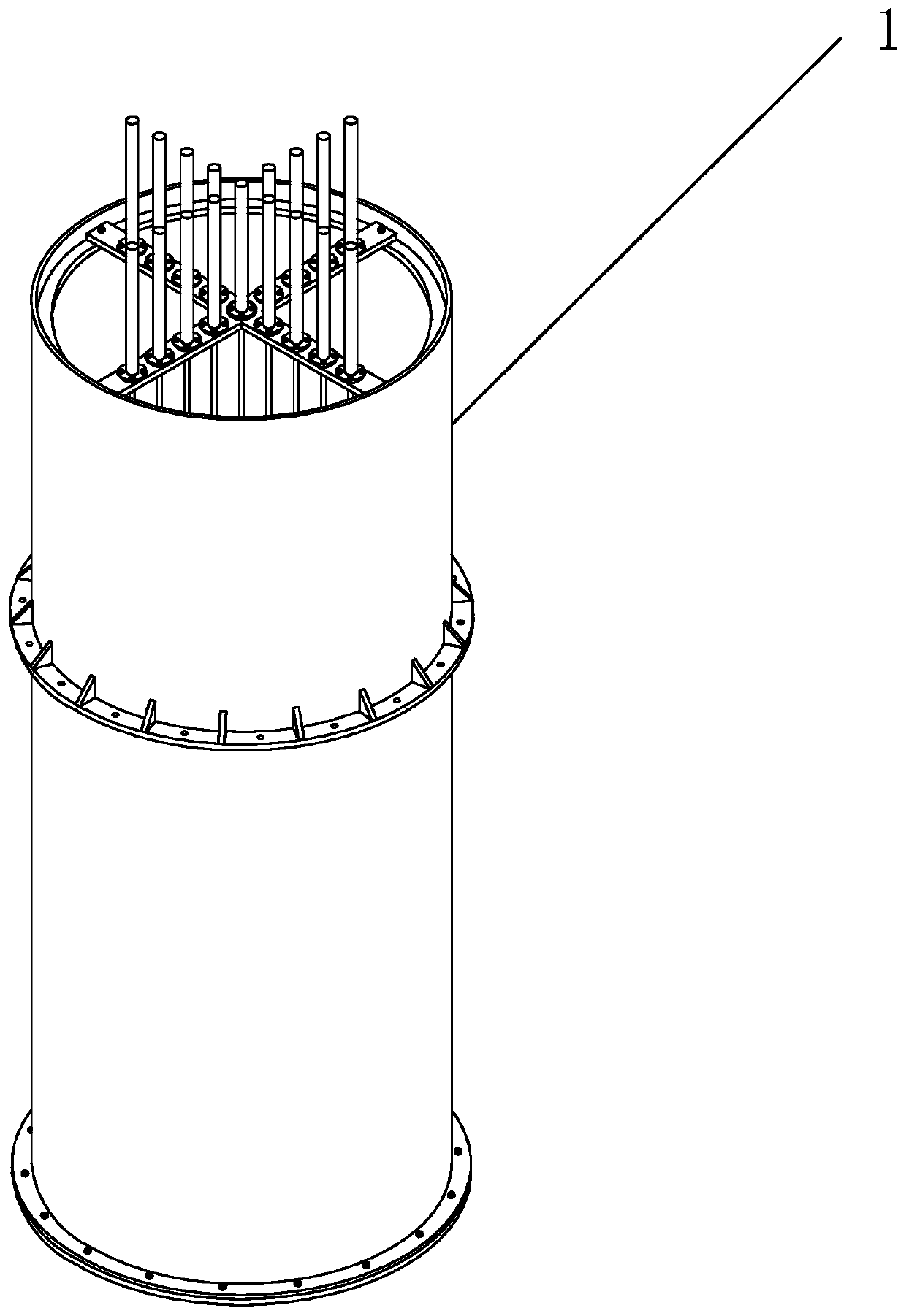

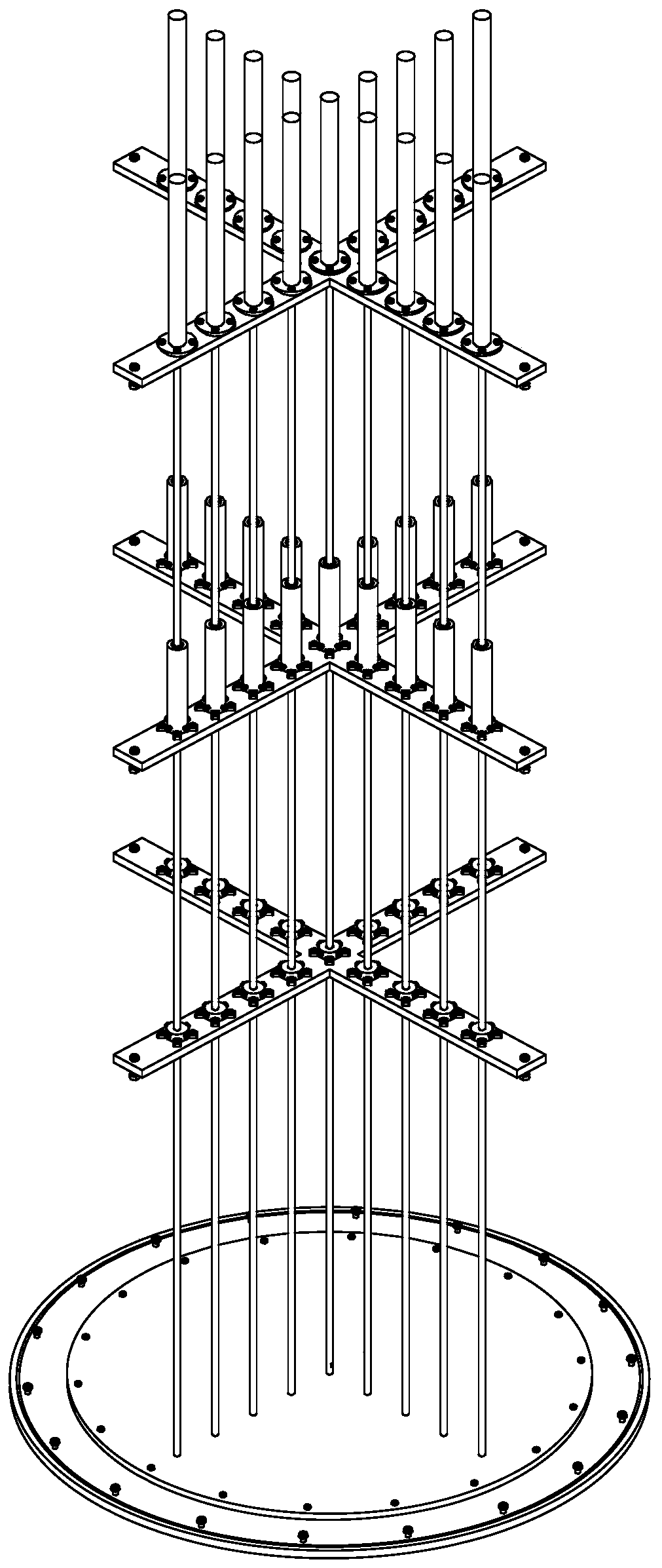

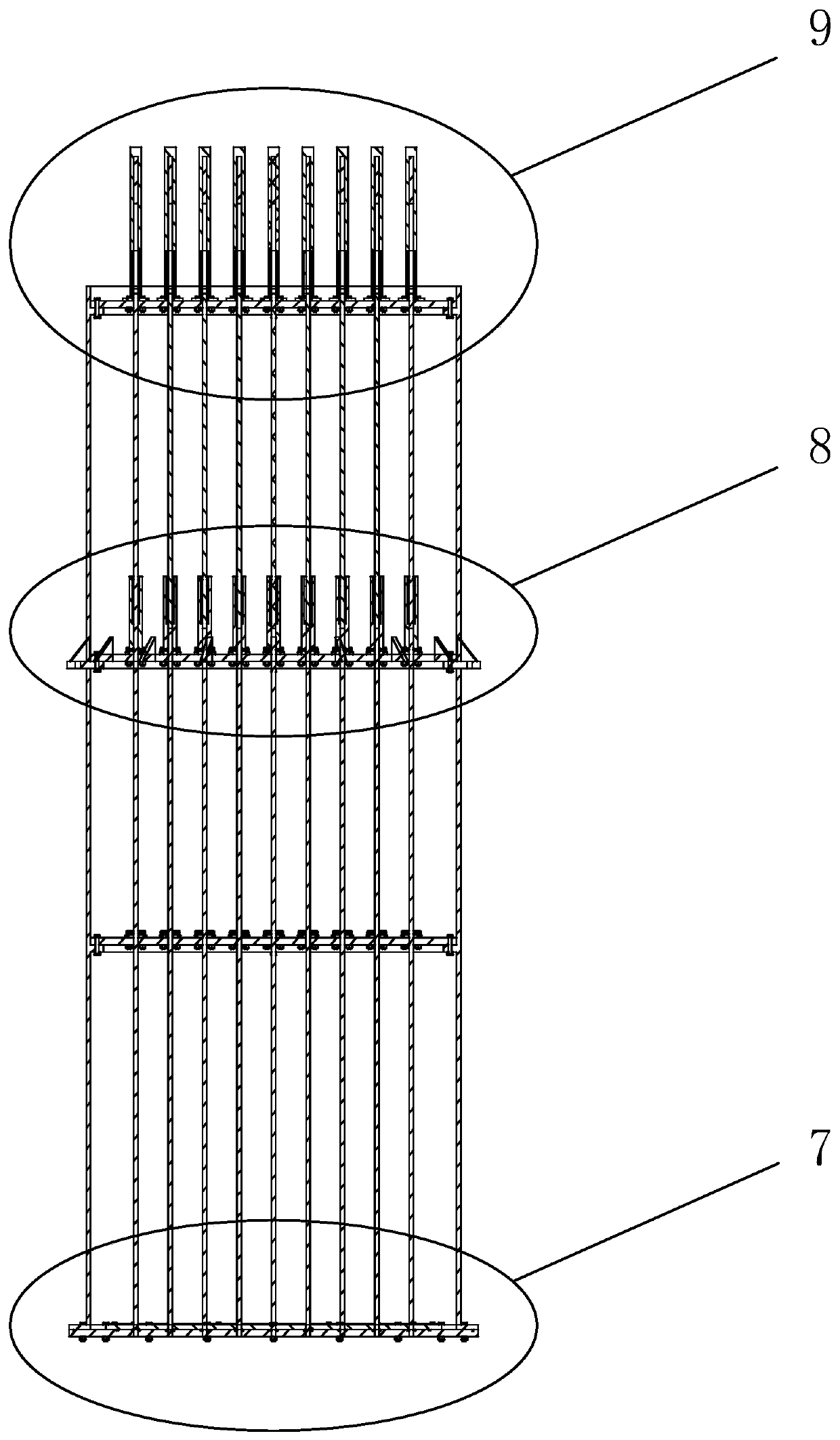

[0025] The invention relates to a cross-array underwater explosion pressure load space distribution measuring device 1 based on Hopkinson rods. This pressure load continuous measurement device is mainly used for the spatial distribution of spherical shock wave pressure load and bubble jet load on the surface of structures generated by underwater near-field explosions. This pressure load measurement device 1 has: cross array Hopkinson bar load The measuring element 7 is used for continuously measuring the spatial distribution of the underwater near-field explosion shock wave and the bubble jet load on the target plate surface. The cross array type load transmission separation device 8, its main function is that the shock wave pressure load passes through the contact surface of the Hopkinson rod 706 and the flyer 806, and after it is completely transmitted into the flyer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com