Easy-open sealing film and use thereof

A sealing film and easy-opening technology, which can be used in flexible coverings, other chemical processes, transportation and packaging, etc., can solve the problems of heat-sealable finger openings, etc., and achieve excellent finger opening properties and stable tube bubbles excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0219] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited to these examples.

[0220]

[0221] The analysis method and evaluation method of the ethylene-based polymer (A1) are as described in the above description, and the methods not described in the above description are as follows. The same is true for the analysis and evaluation methods of ethylene-based polymers other than ethylene-based polymers (A1).

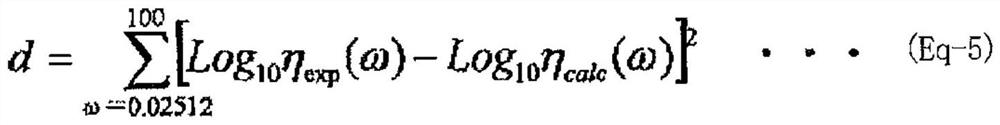

[0222] [Zero-shear viscosity (η 0 )]

[0223] Zero shear viscosity at 200°C [η 0 (P)] is obtained as follows.

[0224] Shear viscosity (η * ) The angular velocity [ω(rad / sec)] distribution was measured in the range of 0.02512≤ω≤100. For the measurement, a dynamic stress rheometer SR-5000 manufactured by Rheometrics Co., Ltd. was used. The sample holder used The parallel plate, the sample thickness is set to about 2.0mm. The measurement points were measured at 5 points for each order...

preparation example X

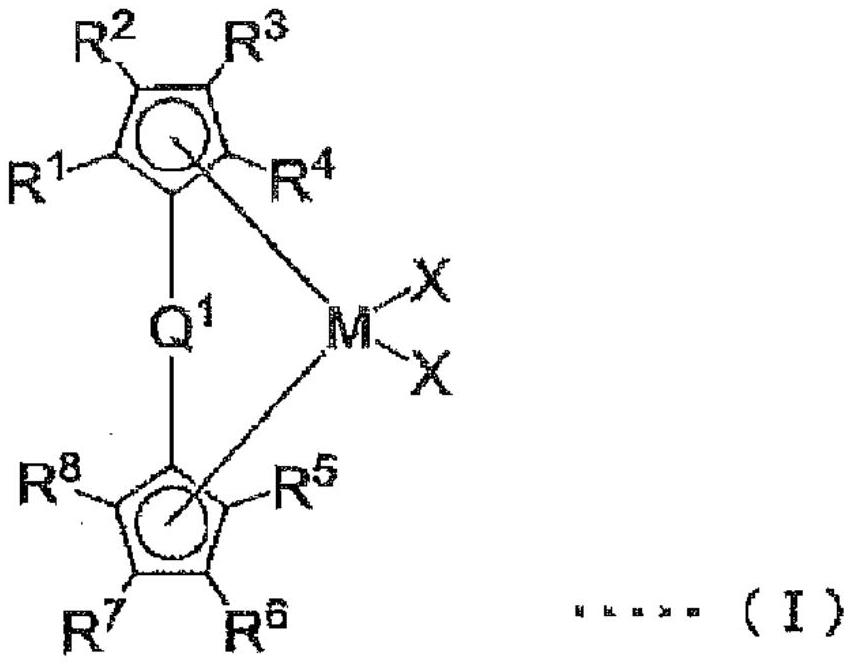

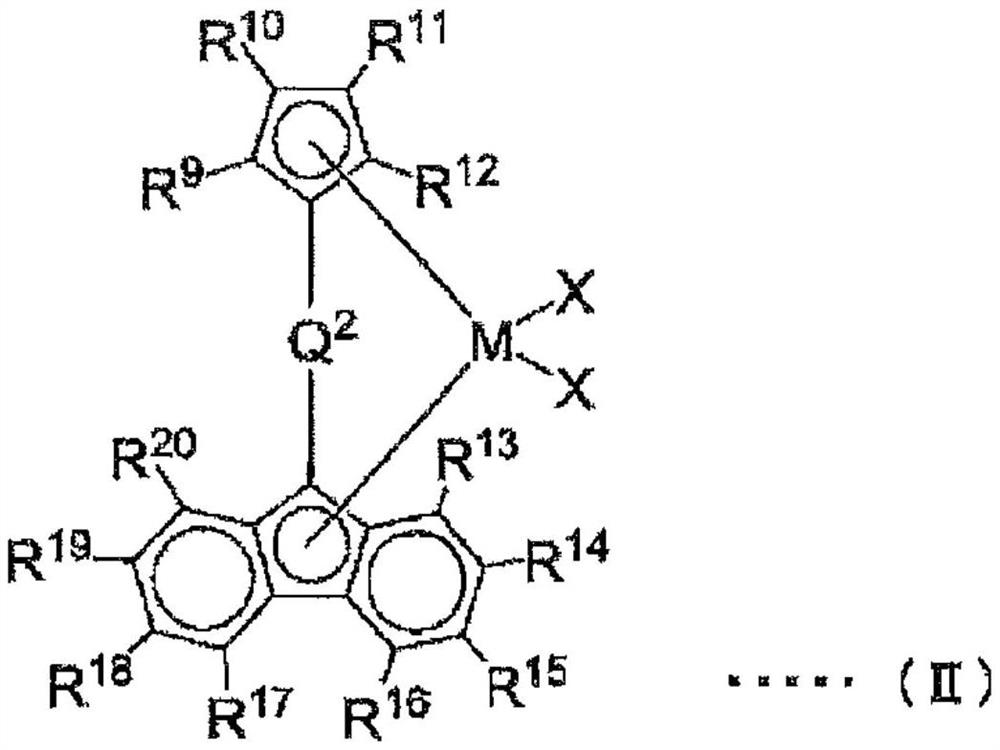

[0271] Based on the descriptions of "Catalyst Preparation Example XP-1", "Catalyst Preparation Example XP-2" and "Catalyst Preparation Example XP-3" of Japanese Patent Application Laid-Open No. 2017-25340, pre-polymerization catalyst components (XP-1) were produced respectively , (XP-2), (XP-3). A specific production method will be described below.

preparation example XP-

[0272] [Catalyst Preparation Example XP-1]

[0273] (Preparation of solid support (X-1))

[0274] In a reactor with a stirrer with an inner volume of 270 liters, under a nitrogen atmosphere, silica gel (manufactured by Fuji SILYSIA Co., Ltd.: average particle size 70 μm, specific surface area 340 m 2 / g, micropore volume 1.3cm 3 / g, dried at 250°C for 10 hours) 10kg was suspended in 77 liters of toluene and cooled to 0-5°C. To this suspension, 19.4 liters of a toluene solution of methylaluminoxane (3.5 mmol / mL in terms of Al atoms) was dropped over 30 minutes. At this time, the temperature in the system was maintained at 0 to 5°C. After continuing the contact at 0-5°C for 30 minutes, the temperature in the system was raised to 95°C over about 1.5 hours, and the contact was continued at 95°C for 4 hours. After cooling down to normal temperature, the supernatant was removed by decantation, and washed twice with toluene to prepare a toluene slurry with a total amount of 115 l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap