Imaging lens, imaging optical device, digital instrument, and production method for imaging lens

A manufacturing method and technology of an optical device are applied in the field of shooting lenses to achieve high-performance image input function and uniform image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

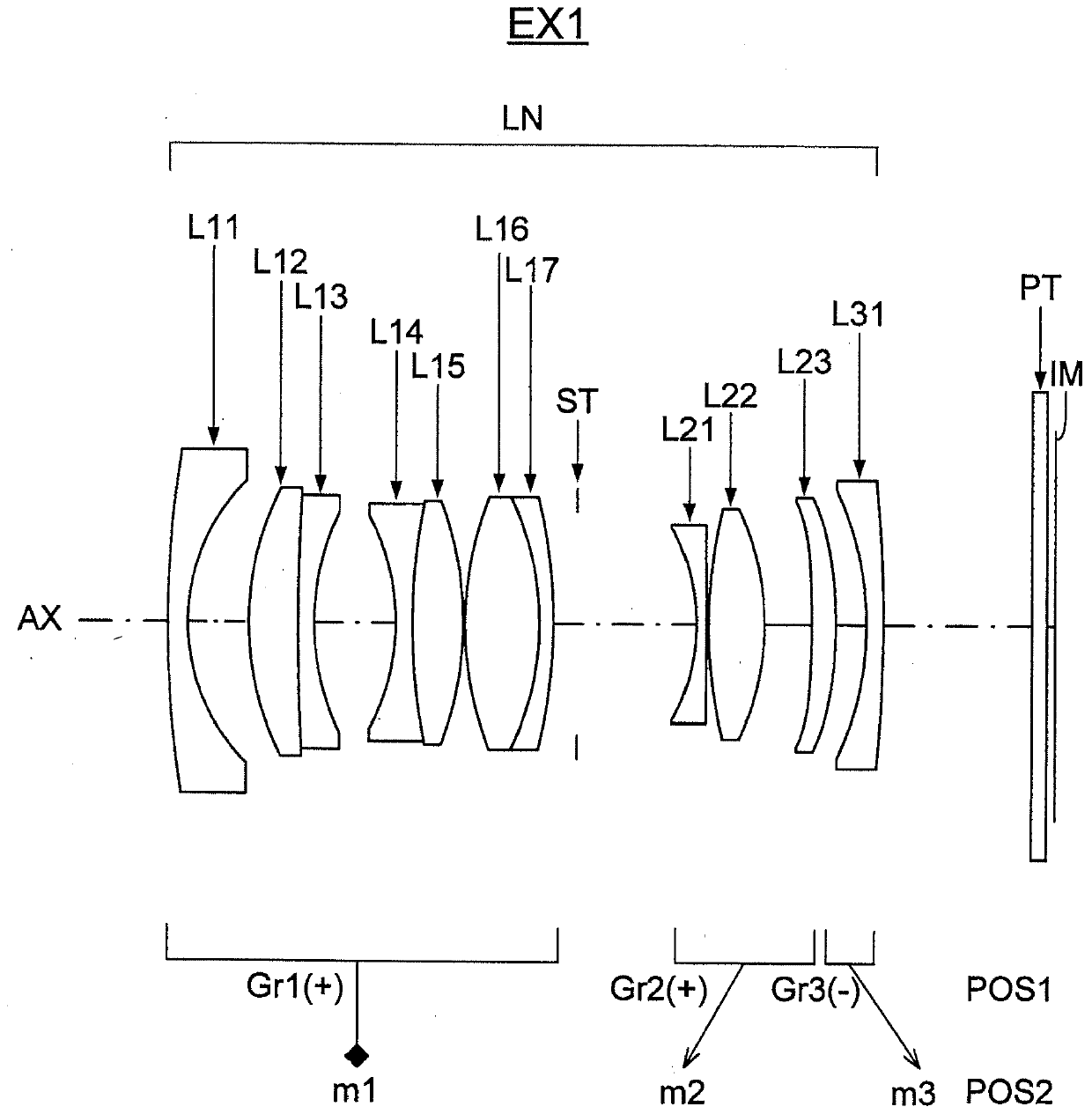

Embodiment 1

[0170] Unit: mm

[0171] surface data

[0172]

[0173] Aspheric Data

[0174]

[0175]

[0176] various data

[0177]

[0178] variable parameter

[0179]

[0180] Group movement amount (POS1→POS2)

[0181] Gr2 Gr3

[0182] -0.228 0.206

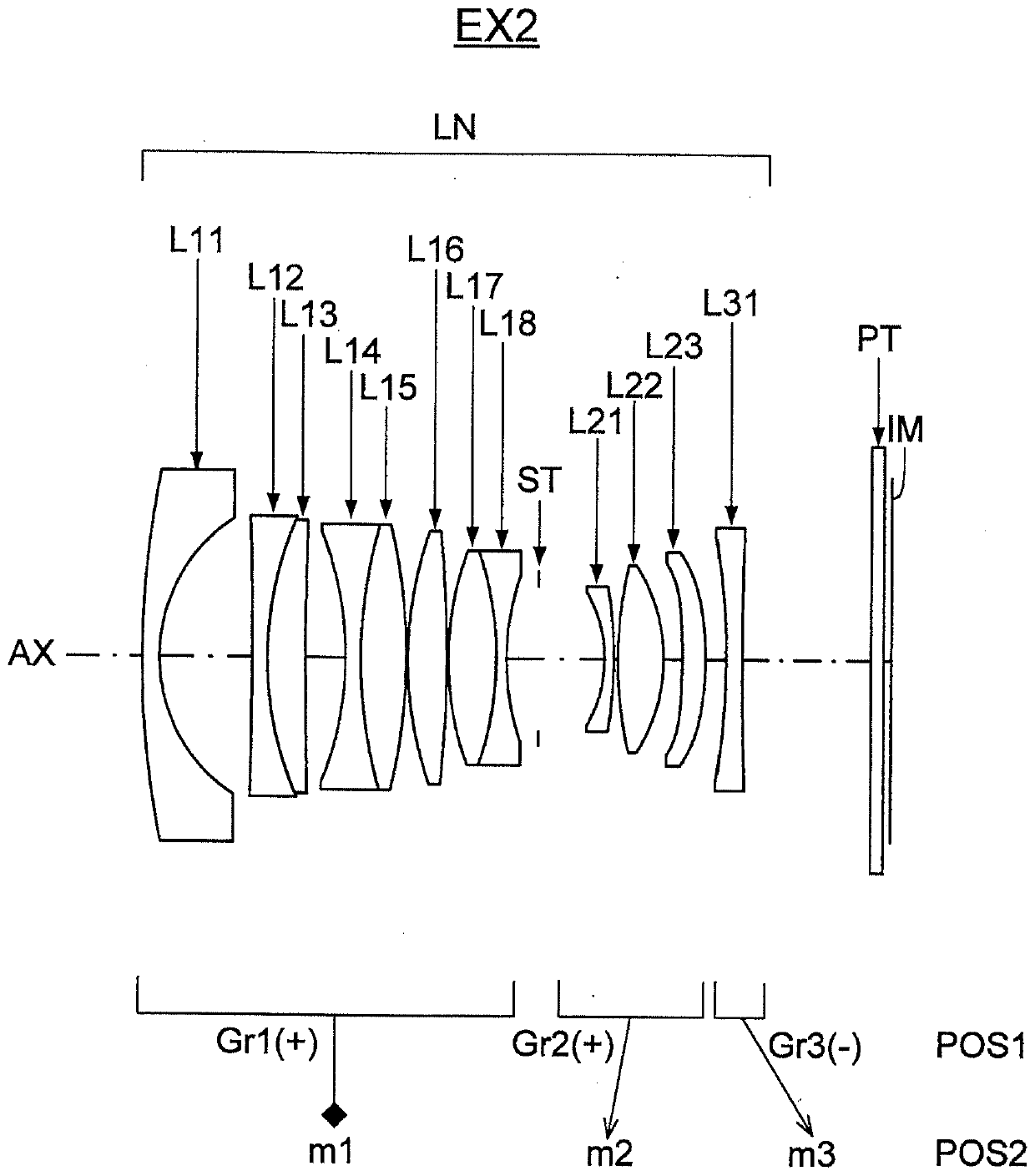

Embodiment 2

[0184] Unit: mm

[0185] surface data

[0186]

[0187]

[0188] Aspheric Data

[0189]

[0190] various data

[0191]

[0192] variable parameter

[0193]

[0194] Group movement amount (POS1→POS2)

[0195] Gr2 Gr3

[0196] -0.088 0.194

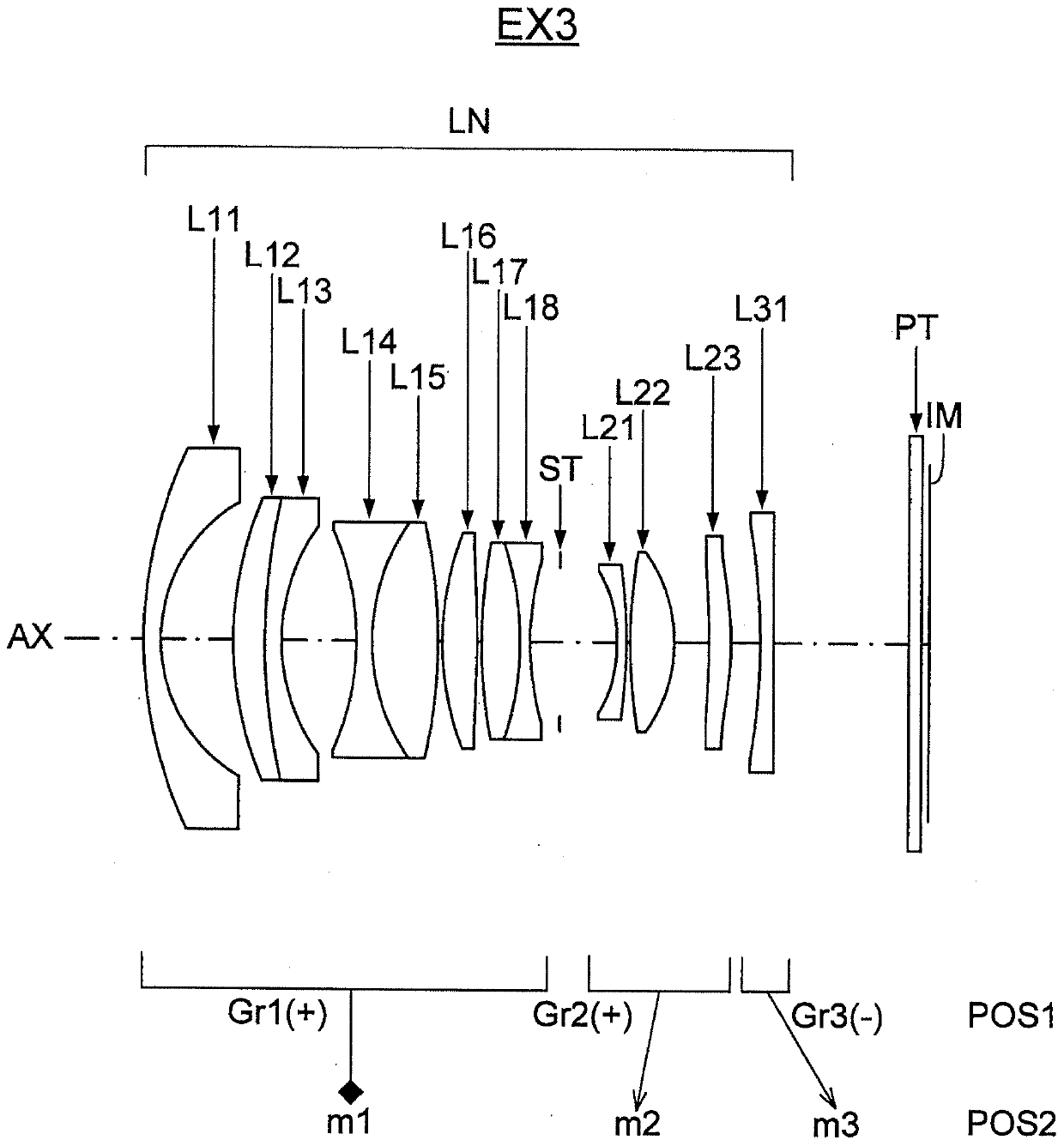

Embodiment 3

[0198] Unit: mm

[0199] surface data

[0200]

[0201]

[0202] Aspheric Data

[0203]

[0204]

[0205] various data

[0206]

[0207] variable parameter

[0208]

[0209] Group movement amount (POS1→POS2)

[0210] Gr2 Gr3

[0211] -0.083 0.226

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com