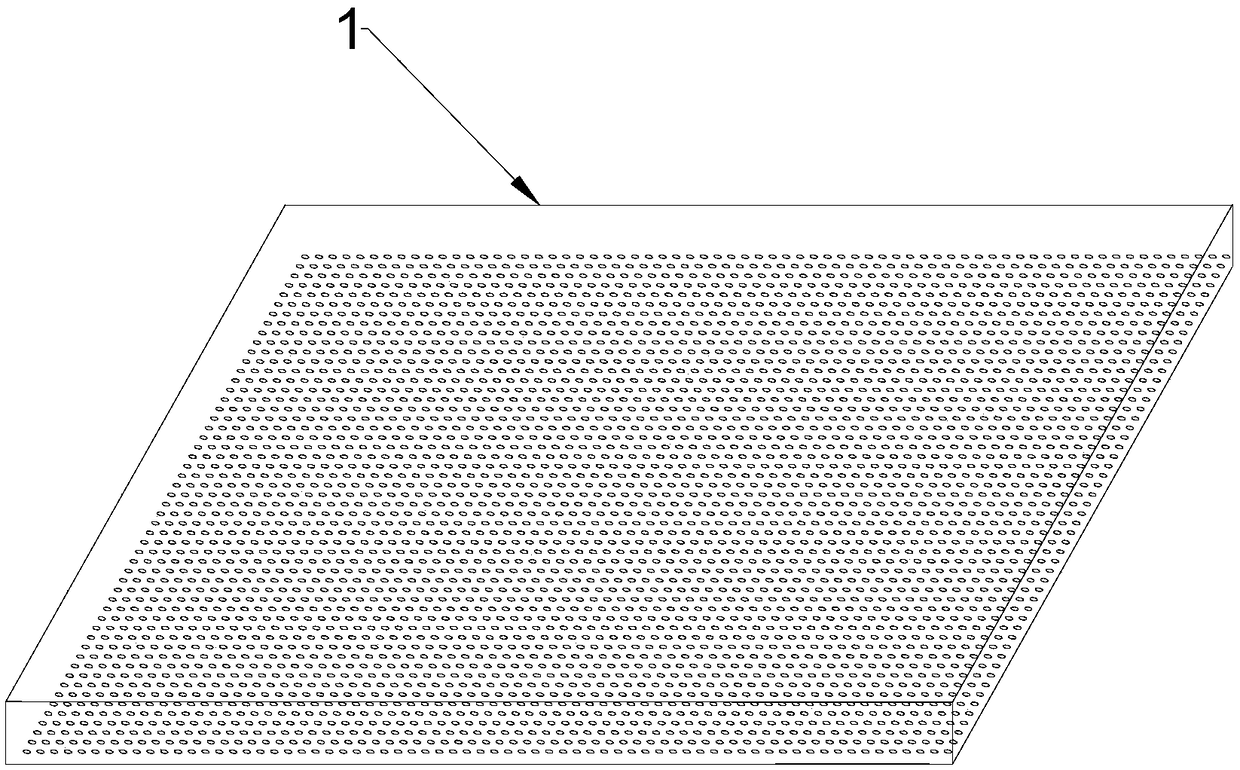

Micro-structure light guide plate and display module thereof

A light guide plate and microstructure technology, applied in the field of light guide plates, can solve the problems of thick thickness of the whole machine, uneven grooves, difficult to make appearance effects, etc., and achieve the effect of improving strength, increasing smoothness and diffuse reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions used in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine experiments.

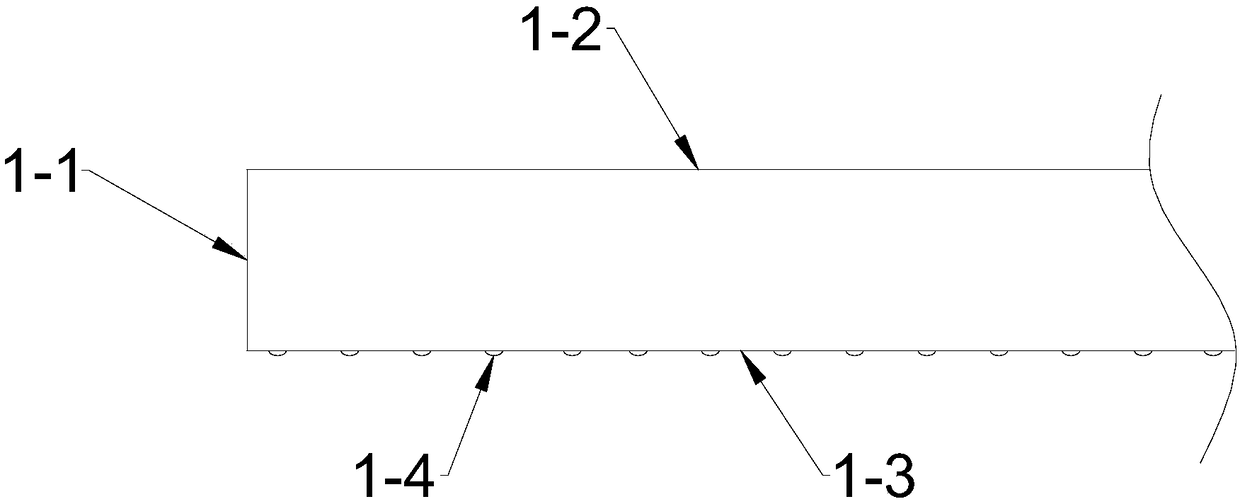

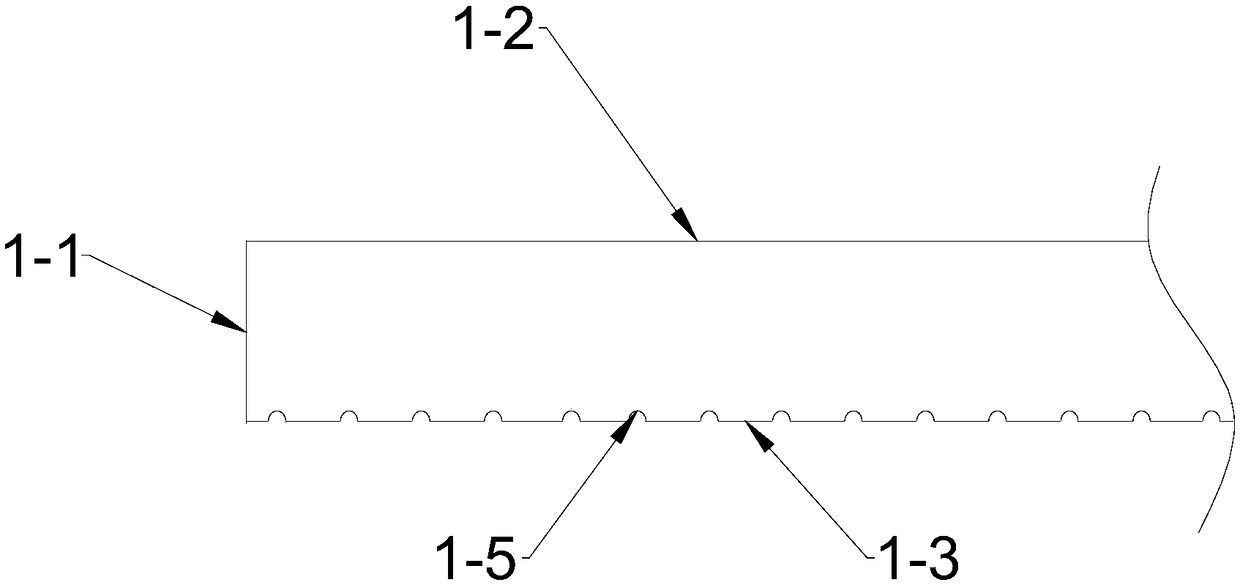

[0034] see Figure 5 , which is a structural schematic diagram of the present invention, provides a microstructured light guide plate, including a light guide plate body 100, the light guide plate body 100 has a light incident surface 101, a light exit surface 102, and a back surface 103, and several micro grooves are arranged on the back surface Structure 104, the improvement of the present invention is that a resin layer 105 is deposited on the back side 103, and the resin layer 105 is one of epoxy resin, phen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com