Automatic powder coating equipment

A powder-coating and automatic technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of low work efficiency, labor consumption of workers, uneven application of tablet lubricant, etc., to achieve high work efficiency, Simple smear work, even smear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

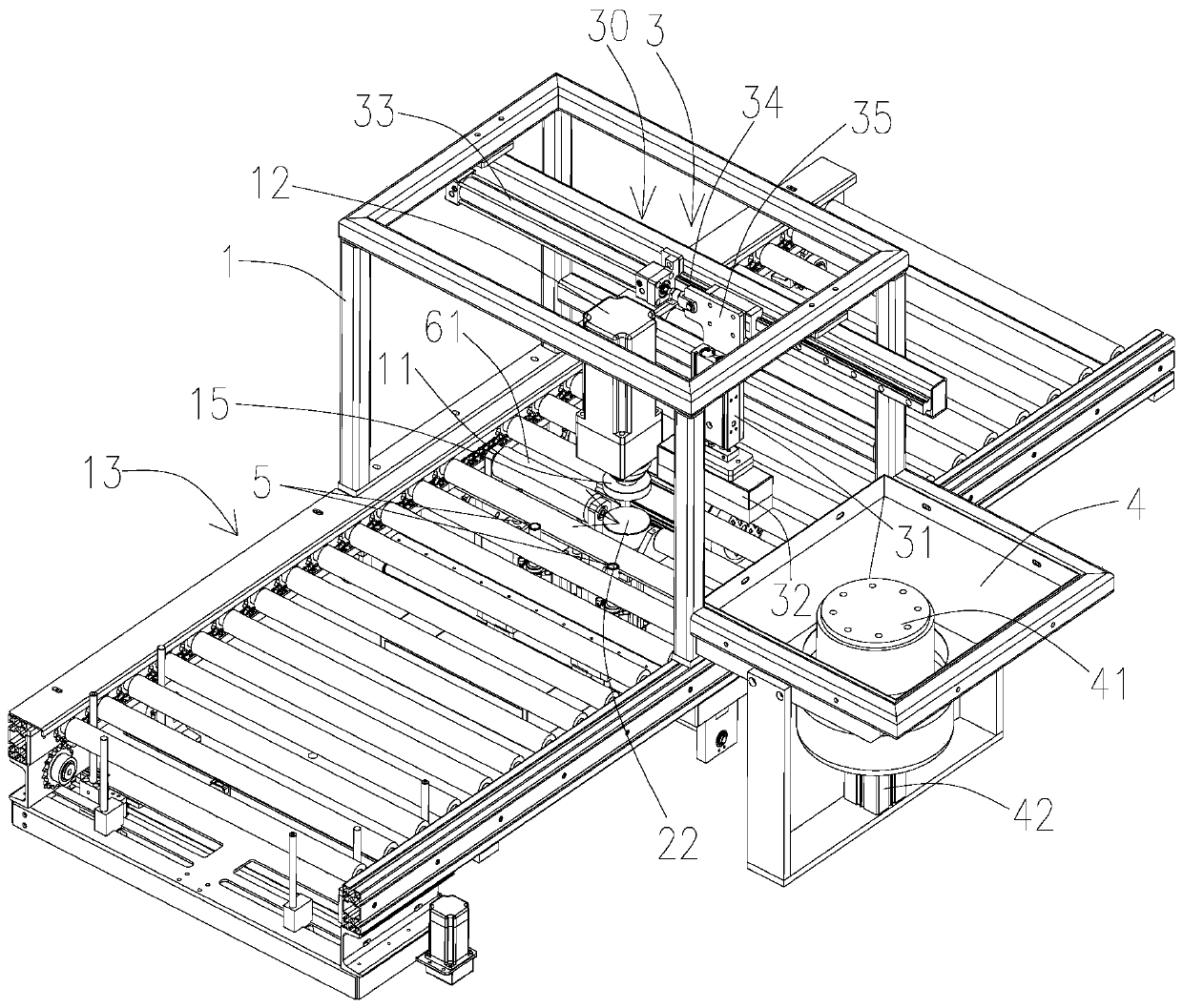

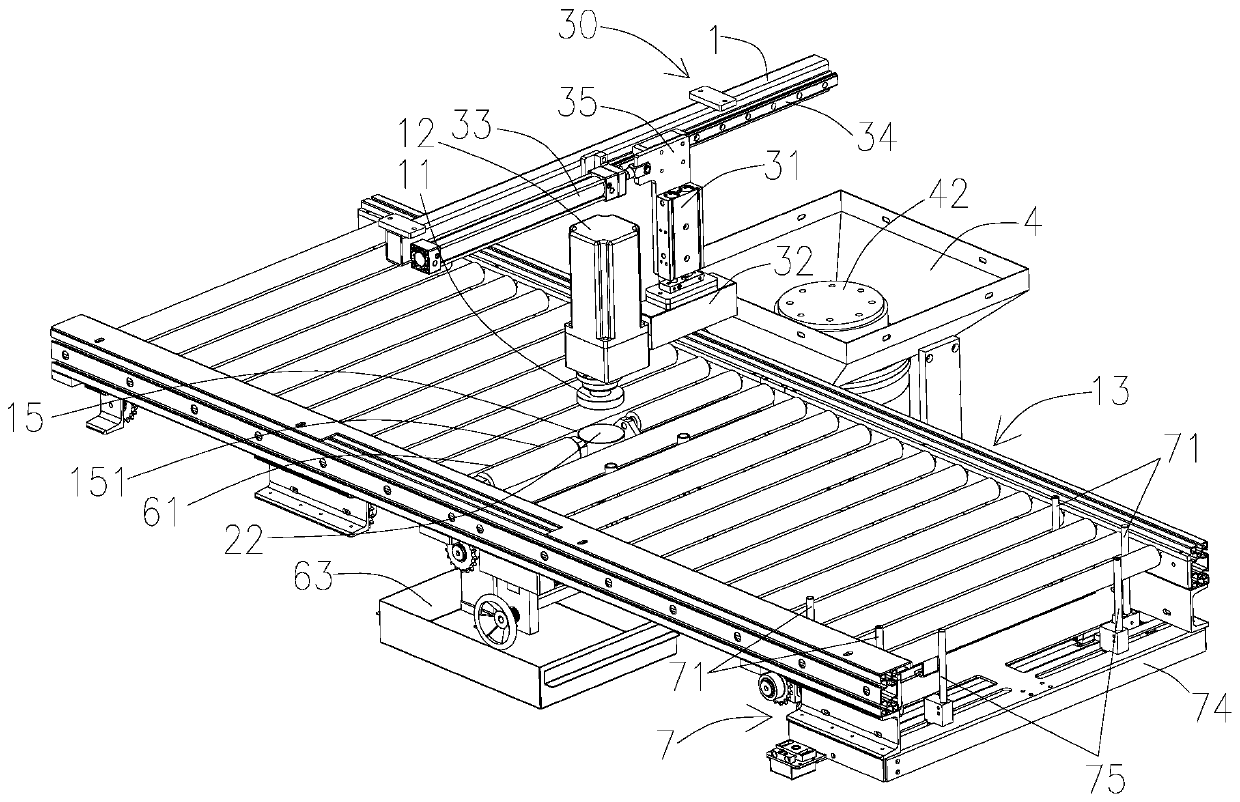

[0026] The technical scheme of the present invention is illustrated below in conjunction with accompanying drawing:

[0027] see Figure 1 to Figure 4 , the automatic powder coating equipment of the present invention comprises: a frame 1; and a rotating pallet 22 supporting workpieces; a rotating fixture 11 that fixes the work on the rotating pallet 22; driving the rotating fixture 11 or the rotating pallet 22 Rotating workpiece driving device 12; at least one powder coating mechanism 3, said powder coating mechanism 3 includes: a powder bin 4 loaded with lubricating powder; a powder brushing part 32 that takes lubricating powder from the powder bin 4 and smears it on the outer surface of the workpiece; The transfer device 30 that drives the powder brushing part 32 to move between the powder bin 4 and the powder brushing position close to the rotary pallet 22; the powder coating driver 31 that connects the powder brushing part 32 and the transfer device; when in the powder bru...

Embodiment 2

[0037] see Figure 5 to Figure 7 , The main difference between this embodiment and Embodiment 1 is that the powder coating mechanism is provided with two, respectively the first powder coating mechanism 3 mechanism and the second powder coating mechanism 8, the first powder coating mechanism 3 mechanism and the second powder coating mechanism The 8 mechanisms of the two powder coating machines are each equipped with an independent powder bin 4. The first powder coating machine 3 mechanism is set in the same way as the powder coating mechanism in Embodiment 1, and the second powder coating machine 8 mechanism replaces the powder coating mechanism. The oil mechanism 6 is arranged on the lower side of the workpiece conveying mechanism 13, and the workpiece conveying mechanism 13 is provided with a second avoidance opening 151 corresponding to the second powder coating mechanism 8, and the second avoidance opening 151 is arranged on the side of the rotary pallet 22 part, it is con...

Embodiment 3

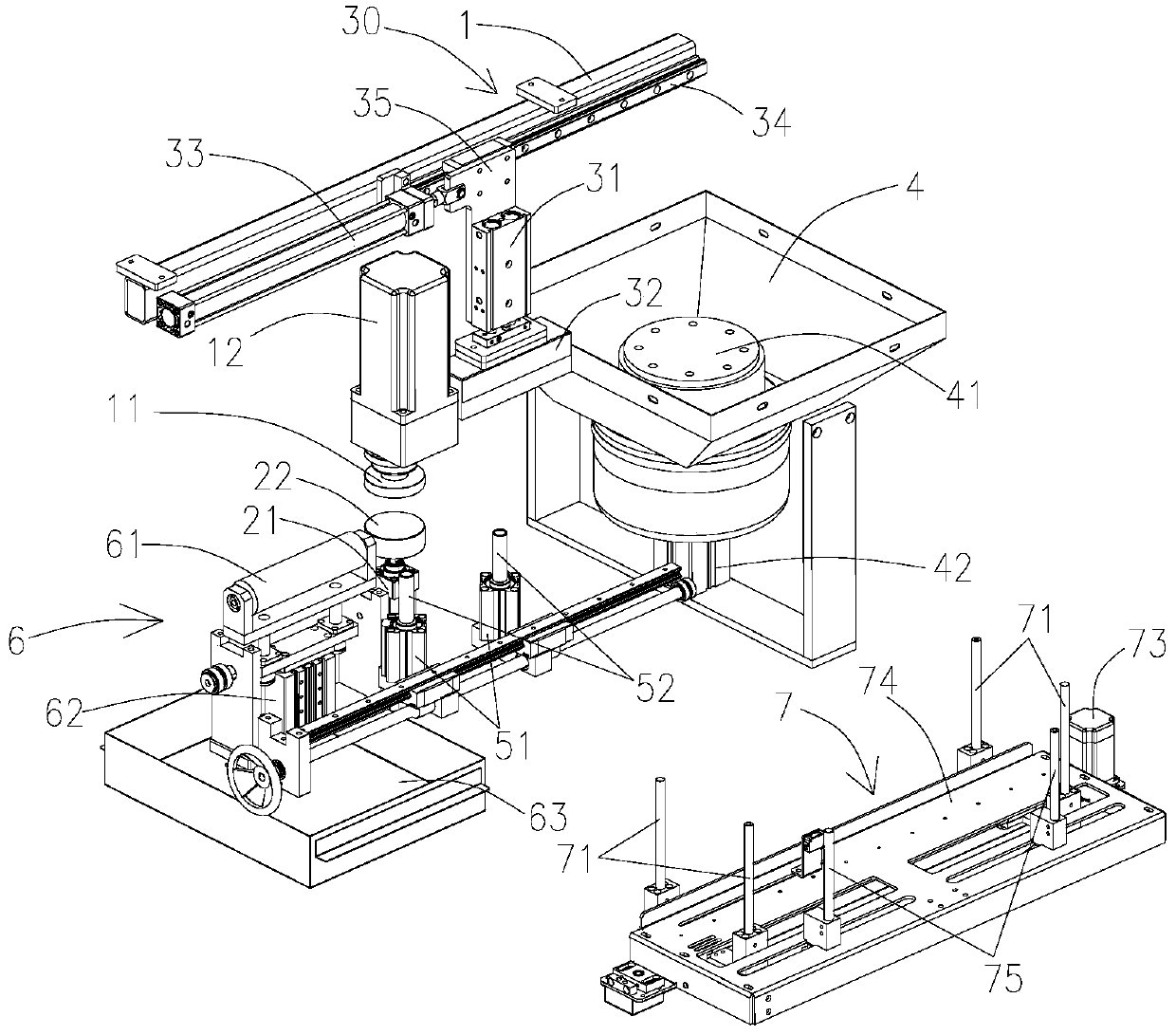

[0042] see Figure 8, the automatic powder coating equipment of this embodiment is used for the second stretching of the pot liner for lubrication treatment, the outer surface of the pot liner needs to be powder coated, and the automatic powder coating method of manual feeding is adopted, Therefore, there is no need to set up a workpiece conveying mechanism 13. The main difference between this embodiment and Embodiment 1 is that the rotating platform 22 is provided with a positioning portion 111 that matches the opening of the pot liner, and the rotating fixing device 11 is located on the On the upper side of the rotating platform 22, the workpiece driving device 12 drives the rotating platform 22 to rotate, and the rotating fixing device 11 relatively drives the rotating supporting platform 22 to rise or fall by the vertical driving device 21. The rotating fixing device 11 is rotatably connected with the vertical driving device 21, and the vertical driving device 21 is prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com