Rubber string waistband sewing method

A technology of elastic and waist, which is applied in the field of clothing sewing, can solve problems such as deformation and easy rolling of elastic, and achieve the effect of stylish trouser waist, high-quality craftsmanship, and rich texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for sewing an elastic waist, comprising:

[0033] 1) Soak the oak root in warm water for 20 minutes to shrink, and then dry it naturally;

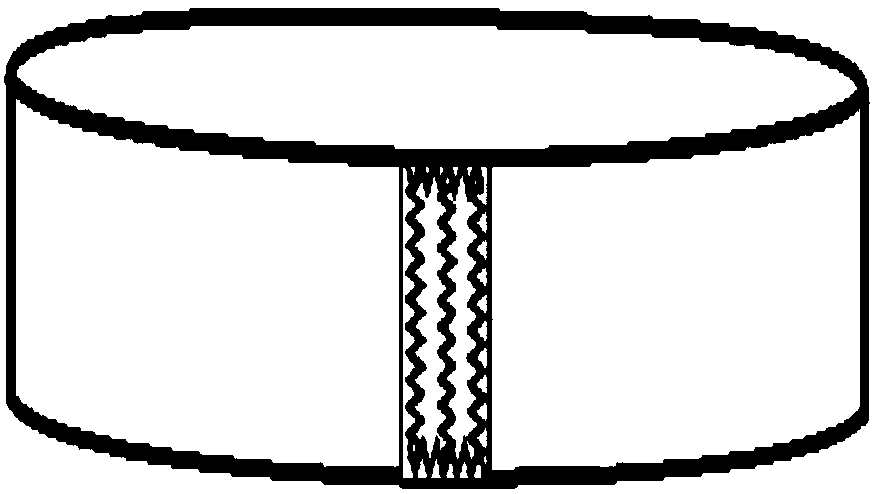

[0034] 2) According to the net sample line of the print, the width of the elastic band is 4.5CM;

[0035] 3) Use 7500 li cloth for elastic splicing, cut 2CM wide strips and wrap the elastic car with zigzag stitches three times to keep the elasticity firm;

[0036] 4) The waist is seamed with flat car elastic thread, and the seams are ironed and smoothed;

[0037] 5) The seam at the waist is buttoned and ironed according to the net sample, and the size is accurate and straight;

[0038] 6) Wrap the rubber band at the lower stop outside the waist surface and fix the rubber band for one week according to the large stitch size at the position 1.3 cm outside and 1.3 cm down from the clean print;

[0039] 7) The waist seam is sewn together with the body, the side seams are aligned with the outer seam of the body, the sewing fo...

Embodiment 2

[0044] A method for sewing an elastic waist, comprising:

[0045] 1) Take a rubber band with a width of 4.5cm, soak it in warm water for 20 minutes, and dry it naturally;

[0046] 2) According to the net sample line of the print;

[0047] 3) splicing the elastic end to end, and seaming the seam with strip cloth with a width of 2 cm;

[0048] 4) The waist is seamed with flat car elastic thread, and the seams are ironed and smoothed;

[0049] 5) The seam at the waist is printed and buckled according to the net sample;

[0050] 6) The lower stop outside the waist is covered with elastic;

[0051] 7) The waist seam is sewn together with the body, and the side seam is aligned with the outer seam of the body;

[0052] 8) The seam of the waist and the body is pressed upside down on the elastic, and the top seam is pressed 1.5cm below the waist, the stitch distance is 8 stitches / 2cm, and the top stitch is 0.1cm at the bottom;

[0053] 9) Press the seam down 1.5cm on the waist sur...

Embodiment 3

[0055] A method for sewing an elastic waist, comprising:

[0056] 1) Take a rubber band with a width of 4.5cm, soak it in warm water for 20 minutes, and dry it naturally;

[0057] 2) According to the net sample line of the print;

[0058] 3) splicing the elastic end to end, and seaming the seam with strip cloth with a width of 2 cm;

[0059] 4) The waist is seamed with flat car elastic thread, and the seams are ironed and smoothed;

[0060] 5) The seam at the waist is printed and buckled according to the net sample;

[0061] 6) The lower stop outside the waist is covered with elastic;

[0062] 7) The waist seam is sewn together with the body, and the side seam is aligned with the outer seam of the body;

[0063] 8) The seam of the waist and the body is pressed upside down on the elastic, and the top seam is pressed 1.5cm below the waist, the stitch distance is 8 stitches / 2cm, and the top stitch is 0.1cm at the bottom;

[0064] 9) Press the seam down 1.5cm on the waist sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com