Curve waistband sewing method

A waist and curve technology, applied in the field of curve waist sewing, can solve the problems of easy curling and deformation of elastic bands, and achieve the effect of precise grasp, three-dimensional shape and overall quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A curved waist sewing method, such as Figure 1~3 shown, including:

[0025] 1) Soak the elastic in warm water for 20 minutes to shrink, then dry naturally;

[0026] 2) Draw the net printing line according to the layout;

[0027] 3) The width of the elastic band is 5cm, cut off according to the length of the pattern;

[0028] 4) The waist fabric is longer than the elastic band according to the size of the paper pattern;

[0029] 5) Glue 1010 plain weave lining on the waist, pass the lining machine, the temperature is 130 ℃, the pressure is 2.5kg;

[0030] 6) The knitted fabric in the waist is shorter than the waist, according to the size of the pattern;

[0031] 7) The bottom seam of the waist is neatly folded and ironed according to the net printing;

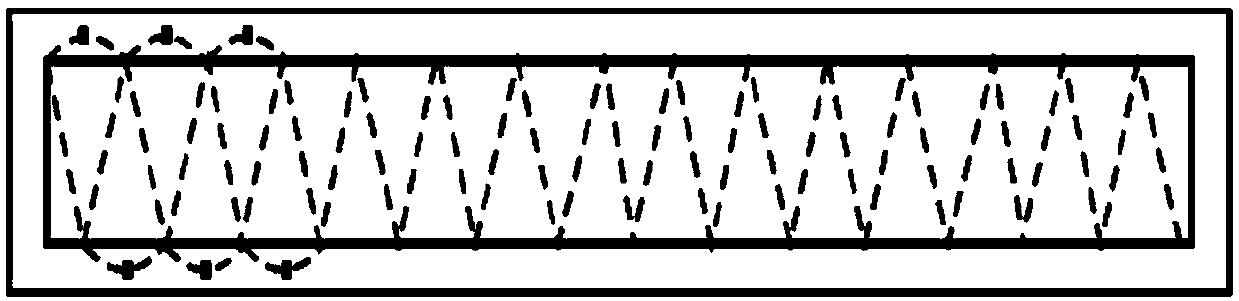

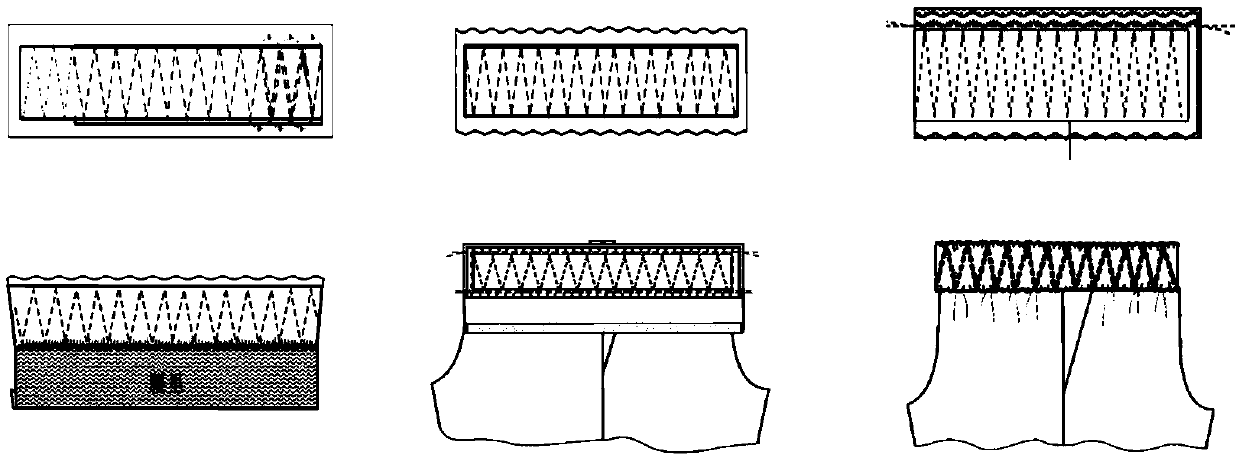

[0032] 8) Lay the elastic fabric on top, follow the net printing line drawn, and overlap the stitches from the curve to the corner to form a sharp corner. The width of the upper and lower waist seams is 1.5cm, and t...

Embodiment 2

[0036] A curved waist sewing method, such as Figure 1~3 shown, including:

[0037] 1) Take a 5cm wide elastic and soak it in warm water for 20 minutes, then dry it naturally;

[0038] 2) Draw the net printing line according to the layout;

[0039] 3) Cut the elastic according to the length of the pattern;

[0040] 4) Glue 1010 plain weave lining on the waist, pass the lining machine, the temperature is 130°C, and the pressure is 2.5kg;

[0041] 5) The bottom seam of the waist is neatly folded and ironed according to the net printing;

[0042] 6) Flatten the elastic band, spread the fabric on it, follow the net printing line and outer stitching line drawn, and overlap the stitches from the curve to the corner to form a sharp corner, and fold back the stitching line with a width of 1.5cm at the top and bottom of the waist and blend it back into 0.2cm; The spacing between the elastic lines is 8 stitches / 2cm;

[0043] 7) When splicing the outer waist and the waist, the waist...

Embodiment 3

[0046] A curved waist sewing method, such as Figure 1~3 shown, including:

[0047] 1) Take a 5cm wide elastic and soak it in warm water for 20 minutes, then dry it naturally;

[0048] 2) Draw the net printing line according to the layout;

[0049] 3) Cut the elastic according to the length of the pattern;

[0050] 4) Glue 1010 plain weave lining on the waist, pass the lining machine, the temperature is 130°C, and the pressure is 2.5kg;

[0051] 5) The bottom seam of the waist is neatly folded and ironed according to the net printing;

[0052] 6) Flatten the elastic band, spread the fabric on it, follow the net printing line and outer stitching line drawn, and overlap the stitches from the curve to the corner to form a sharp corner, and fold back the stitching line with a width of 1.5cm at the top and bottom of the waist and blend it back into 0.2cm; The spacing between the elastic lines is 8 stitches / 2cm;

[0053] 7) When splicing the outer waist and the waist, the waist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com