Processing device and processing method for gear

A processing device and processing method technology, applied in the direction of gear tooth manufacturing device, gear tooth manufacturing tool, feeding device, etc., can solve the difficulty in achieving the unity of production efficiency and processing quality, complex structure of gear grinding machine tools, high precision control requirements, etc. problem, to achieve the effect of easy guarantee of gear accuracy and quality, simple adjustment, and simple tool profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

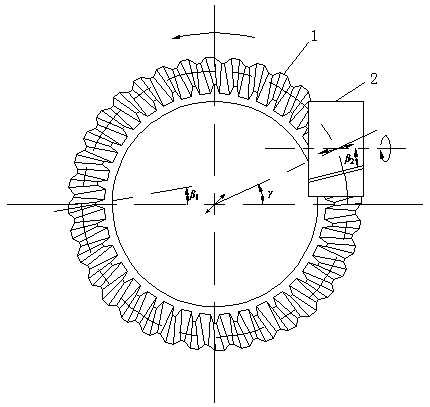

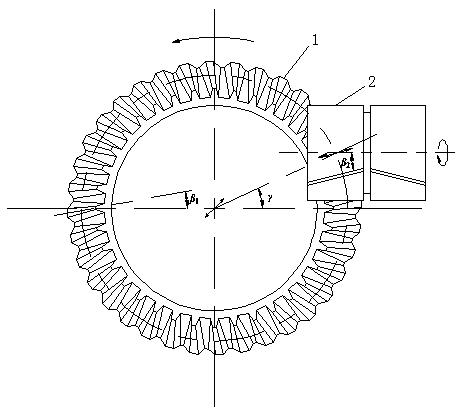

[0020] A processing device for gears, comprising a cutting tool 1, the cutting tool 1 is in the shape of an end gear, the cutting tool 1 is meshed with a gear 2, the gear 2 is a cylindrical gear, and the The helix angle of cutting tool 1 is β 1 , with left-handed as positive and right-handed as negative, the helix angle of the gear 2 is β 2 , with left-handed as positive and right-handed as negative, and the helix angle of cutting tool 1 β 1 with gear 2 helix angle β 2 are not the same, the offset installation angle between the cutting tool 1 and the gear 2 gamma = β 1 + β 2 . Observe that the cylindrical gear is placed on the right side of the end gear-shaped cutting tool 1, and the offset installation angle is positive when the cylindrical gear is offset, and when the offset installation angle is negative, the cylindrical gear is offset downward.

[0021] The specific steps of using the cutting tool 1 for the processing method of the cylindrical gear are as follo...

Embodiment 2

[0026] A processing device for gears, comprising a cutting tool 1, the cutting tool 1 is in the shape of an end gear, the cutting tool 1 is meshed with a gear 2, the gear 2 is a herringbone gear, and the The helix angle of cutting tool 1 is β 1 , with left-handed as positive and right-handed as negative, the helix angle of the gear 2 is β 2 , with left-handed as positive and right-handed as negative, and the helix angle of cutting tool 1 β 1 with gear 2 helix angle β 2 are not the same, the offset installation angle between the cutting tool 1 and the gear 2 gamma = β 1 + β 2 . When the herringbone gear is placed on the right side of the end face gear-shaped cutting tool 1 and observed, the offset installation angle is positive when the herringbone gear is upper biased, and when the offset installation angle is negative, the herringbone gear is lower biased.

[0027] The specific steps of using the cutting tool 1 for the processing method of the herringbone gear are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com