A kind of c for photoanode x n y /bivo 4 Materials and their preparation methods and applications

A photoanode and photoelectrode technology, which is applied in the field of photoanode material preparation, can solve the problems such as the inability to form an interface, and achieve the effects of low cost, complicated preparation, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] C proposed by the present invention x N y / BiVO 4 A method for preparing a photoanode, comprising the steps of:

[0037] (1) Synthesis of bulk carbon nitride (BCN);

[0038] The method of synthesizing bulk carbon nitride (BCN) is: heating and calcining the mixture of dicyandiamide and urea in the air atmosphere of a tube furnace. Raise the temperature to 300°C, then raise the temperature to 500°C at a rate of 1-4°C / min, then raise the temperature to 550°C at a rate of 1-3°C / min, keep it warm for 2-6 hours, and finally The cooling rate of 1-7°C / min reduces the temperature to 30°C, and the molar ratio of dicyandiamide to urea is 1-4:1;

[0039] (2) Synthesis of carbon nitride hydrogel (CNH);

[0040] The method for synthesizing carbon nitride hydrogel (CNH) is: disperse the bulk carbon nitride (BCN) prepared in step (1) in deionized water, then carry out hydrothermal reaction in the reactor, and the hydrothermal reaction temperature is 150 -250°C, the hydrothermal r...

Embodiment 1

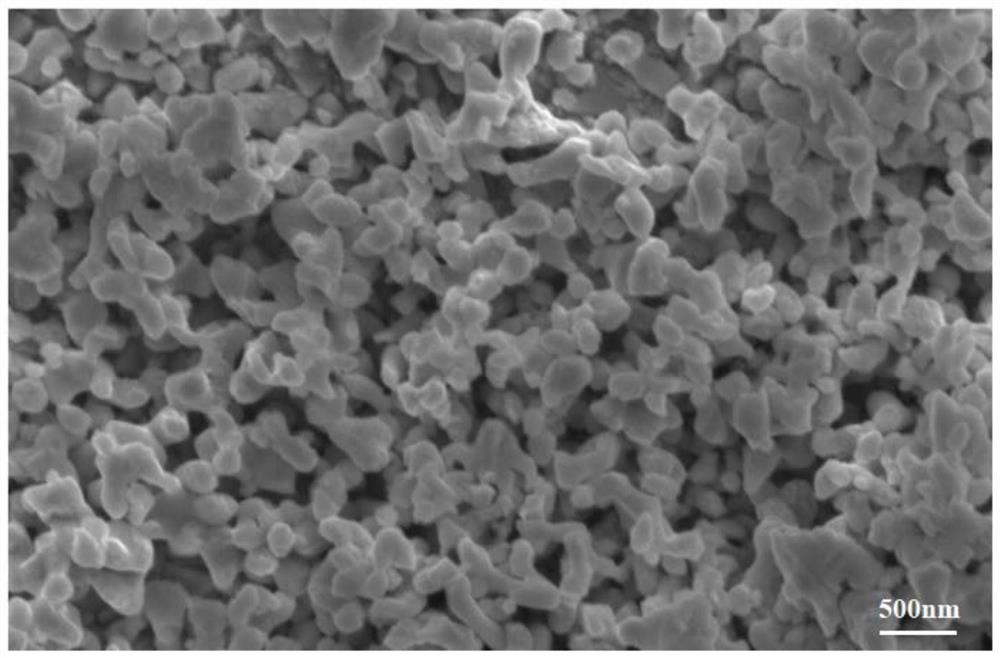

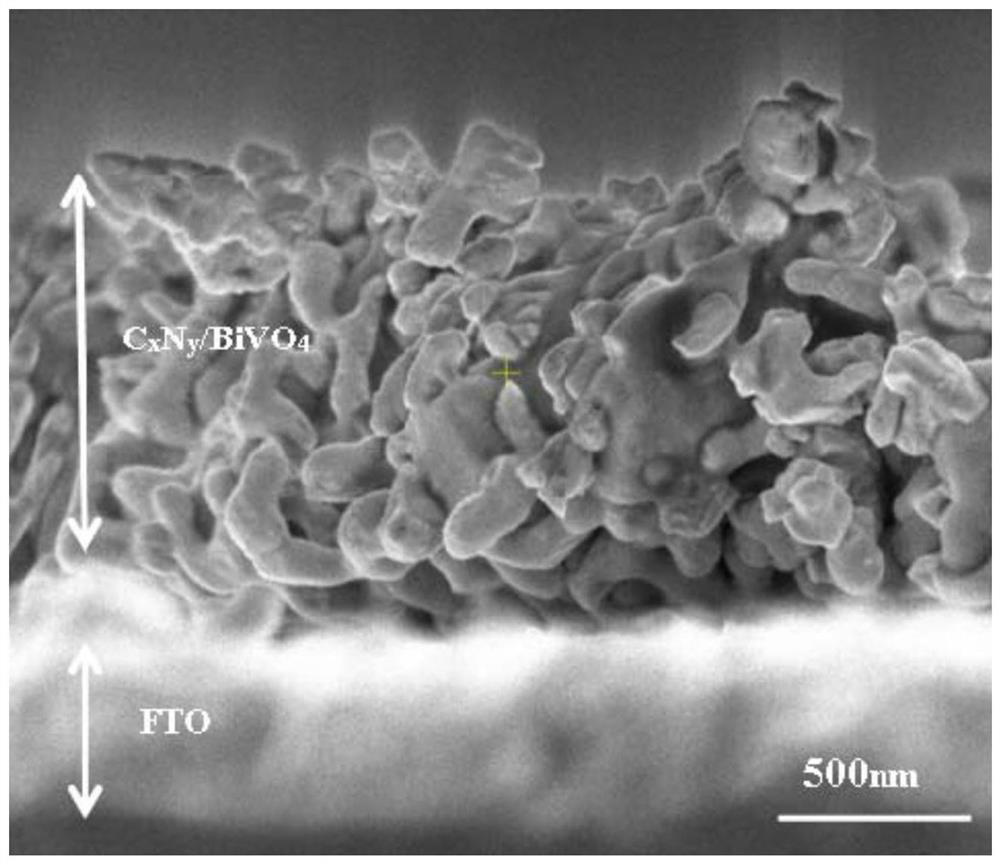

[0058] Embodiment 1, preparation C x N y / BiVO 4 photoanodic method

[0059] (1) Synthesis of bulk carbon nitride (BCN): the mixture of dicyandiamide and urea (4:1 molar ratio) is heated in the air atmosphere of a tube furnace, and the temperature program for calcination is as follows: 30-300 ° C (8 ℃ / min); 300-500℃(2℃ / min); 500-550℃(1℃ / min); 550-550℃(4h); 550-30℃(5℃ / min);

[0060] (2) Synthesis of carbon nitride hydrogel (CNH): 0.5 g of BCN was dispersed in 20 mL of deionized water. Then it was transferred to a 100mL reactor for hydrothermal reaction and kept at 180°C for 5h to obtain a suspension.

[0061] (3) Nanoporous BiVO 4 Electrode synthesis: Dissolve 20mmol KI in 50mL deionized water and stir for 15min, then add HNO 3 Adjust the pH to 1.7. After stirring for 15min, add 2mmol Bi(NO 3 ) 3 ·5H 2 O, and then stirred for 15min to form a plating solution. This solution was mixed with 20 mL of absolute ethanol containing 4.6 mmol p-benzoquinone and stirred vigorou...

Embodiment 2

[0064] Embodiment 2, preparation C x N y / BiVO 4 photoanodic method

[0065] (1) Synthesis of bulk carbon nitride (BCN): the mixture of dicyandiamide and urea (4:1 molar ratio) is heated in the air atmosphere of a tube furnace, and the temperature program for calcination is as follows: 30-300 ° C (8 ℃ / min); 300-500℃(2℃ / min); 500-550℃(1℃ / min); 550-550℃(4h); 550-30℃(5℃ / min);

[0066] (2) Synthesis of carbon nitride hydrogel (CNH): 0.5 g of BCN was dispersed in 20 mL of deionized water. Then it was transferred to a 100mL reactor for hydrothermal reaction and kept at 180°C for 5h to obtain a suspension.

[0067] (3) Nanoporous BiVO 4 Electrode synthesis: Dissolve 20mmol KI in 50mL deionized water and stir for 15min, then add HNO 3 Adjust the pH to 1.7. After stirring for 15min, add 2mmol Bi(NO 3 ) 3 ·5H 2 O, and then stirred for 15min to form a plating solution. This solution was mixed with 20 mL of absolute ethanol containing 4.6 mmol p-benzoquinone and stirred vigorou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com