Filtration apparatus and filtration method

A filtration equipment and filtration chamber technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of difficult recovery, short service life and high cost of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

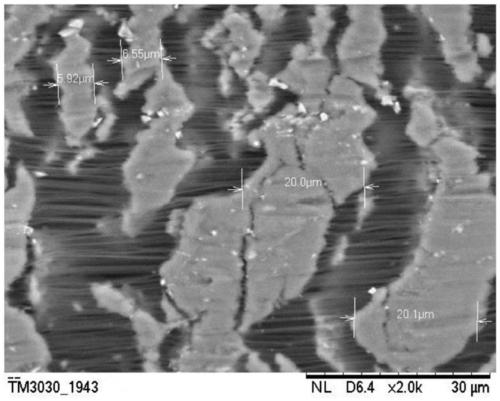

[0026] A flexible ceramic membrane, such as figure 1 Shown, prepared by the following method:

[0027] 1. Mixture:

[0028] Take the following raw materials, add about 125g of co-solvent, and mix well:

[0029] Ceramic membrane particles (TiO2) 7.5g

[0030] PTFE Granules 92.5g

[0031] The particle size of the above-mentioned ceramic membrane particles is 1-5 μm, the particle size of the polytetrafluoroethylene particles is 0.2-0.5 μm, the co-solvent is kerosene, heated to 200-260 ° C, and stirred to wrap the polytetrafluoroethylene around the ceramic membrane particles , forming a composite membrane material;

[0032] 2. Materials:

[0033] Put the above-mentioned composite membrane material in a rod groove and stir it thoroughly for 30 minutes to make a hollow tubular rod.

[0034] 3. Forming: Extrude the above-mentioned tubular bar into a hollow thin tubular material with an inner diameter of 0.5 mm to 10 mm and an outer diameter of 1 mm to 12 mm by extruding at 260°...

Embodiment 2

[0040] The invention relates to an application of a flexible ceramic membrane, which is used as a tubular membrane wire in water purification and filtration equipment.

[0041] The above-mentioned water purification equipment such as Figure 4 As shown, it includes: a casing 100 , a tubular membrane filament 200 , a gas reaction generating device and a cavitation generating device 300 .

[0042] The housing 100 includes a water purification chamber 110, the water purification chamber 110 divides the interior space of the housing 100 into a water purification chamber inside the water purification chamber and a filter chamber outside the water purification chamber, and the water purification chamber is provided with a production The water outlet 111, the filter chamber is provided with a water inlet 121, a cross-flow outlet 123 and a sewage outlet 125; the water production outlet is arranged on the top of the housing, the sewage outlet is arranged on the bottom of the housing, a...

Embodiment 3

[0076] A water purification and filtration equipment, which is basically the same as the equipment in Example 2, the only difference is that the ceramic membrane particles selected for the flexible ceramic membrane are silicon carbide, and the above water purification and filtration equipment is used for wastewater filtration, and it is found that after a period of operation Filtration throughput is severely affected due to bacterial growth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com