Treatment method of high-salt-content organic wastewater

A technology for organic wastewater and treatment methods, which is applied in seawater treatment, water/sewage treatment, water treatment parameter control, etc., and can solve problems such as clogging and salt deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

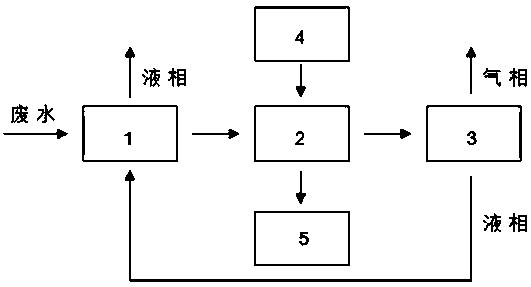

[0030] Adopt the present invention to attach figure 1 In the process shown, in the high-salt organic wastewater, the COD concentration is 92600mg / L, the TDS is 13.5wt%, and the pH is 8.5.

[0031] Pass high-salt organic wastewater and oxygen into the ebullating bed reactor, wherein the solid particles in the ebullating bed reactor are alumina ceramic balls with a diameter of 0.4mm and a bulk density of 0.65g / cm 3 , the specific surface area is 260m 2 / g, the amount of solid particles added is 1 / 2 of the reactor volume. The amount of oxidant introduced is 300% of the theoretical oxygen demand for wastewater oxidation. The conditions of the supercritical oxidation are as follows: the reaction temperature is 600° C., the reaction pressure is 28 MPa, and the reaction residence time is 30 seconds. The amount of solid particles added and discharged during the reaction is 75g h -1 ·L -1 进水. The salt in the wastewater is deposited on the solid particles of the fluidized bed rea...

Embodiment 2

[0034] Adopt the present invention to attach figure 1 In the process shown, in the highly saline organic wastewater, the COD concentration is 21700mg / L, the TDS is 5.3wt%, and the pH is 8.

[0035] Pass high-salt organic wastewater and oxygen into the ebullating bed reactor, wherein the solid particles in the ebullating bed reactor are alumina ceramic balls with a diameter of 0.2mm and a bulk density of 0.67g / cm 3 , the specific surface area is 100m 2 / g, the amount of solid particles added is 1 / 3 of the reactor volume. The amount of oxidant introduced is 150% of the theoretical oxygen demand for wastewater oxidation. The conditions of the supercritical oxidation are as follows: the reaction temperature is 380° C., the reaction pressure is 23 MPa, and the reaction residence time is 150 seconds. The amount of solid particles added and discharged during the reaction is 58g h -1 ·L -1 进水 . The salt in the wastewater is deposited on the solid particles of the fluidized bed ...

Embodiment 3

[0038] Adopt the present invention to attach figure 1 In the process shown, in the high-salt organic wastewater, the COD concentration is 137200mg / L, the TDS is 14.3wt%, and the pH is 8.7.

[0039] Pass high-salt organic wastewater and oxygen into the ebullating bed reactor, wherein the solid particles in the ebullating bed reactor are alumina ceramic balls with a diameter of 0.7mm and a bulk density of 0.62g / cm 3 , the specific surface area is 300m 2 / g, the amount of solid particles added is 1 / 2 of the reactor volume. The amount of oxidant introduced is 350% of the theoretical oxygen demand for wastewater oxidation. The conditions of the supercritical oxidation are as follows: the reaction temperature is 650° C., the reaction pressure is 30 MPa, and the reaction residence time is 30 seconds. The amount of solid particles added and discharged during the reaction is 79g h -1 ·L -1 进水 . The salt in the wastewater is deposited on the solid particles of the fluidized bed r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com