Fly ash washing process for multistage reverse pulping of carbon dioxide tempering

A carbon dioxide and tempering technology, which is applied to chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of high energy consumption, failure to provide washing liquid, and high evaporation water, so as to save water and realize Chlorine removal and calcium slag resource utilization, high recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

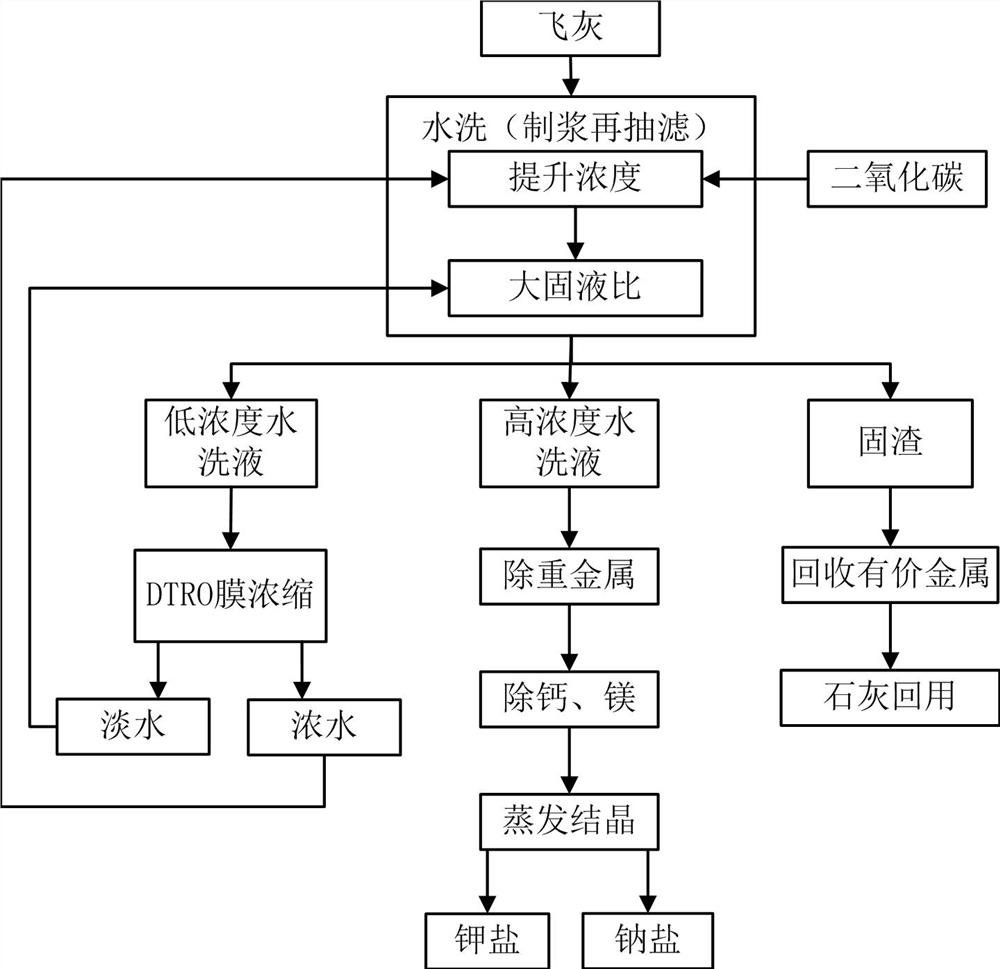

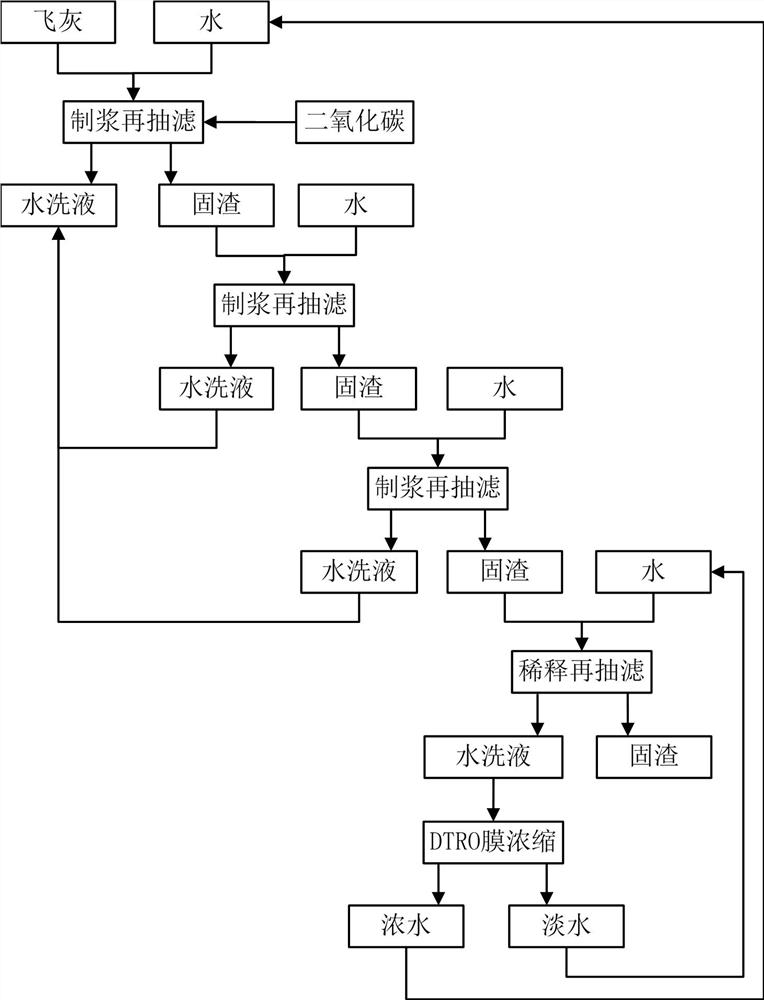

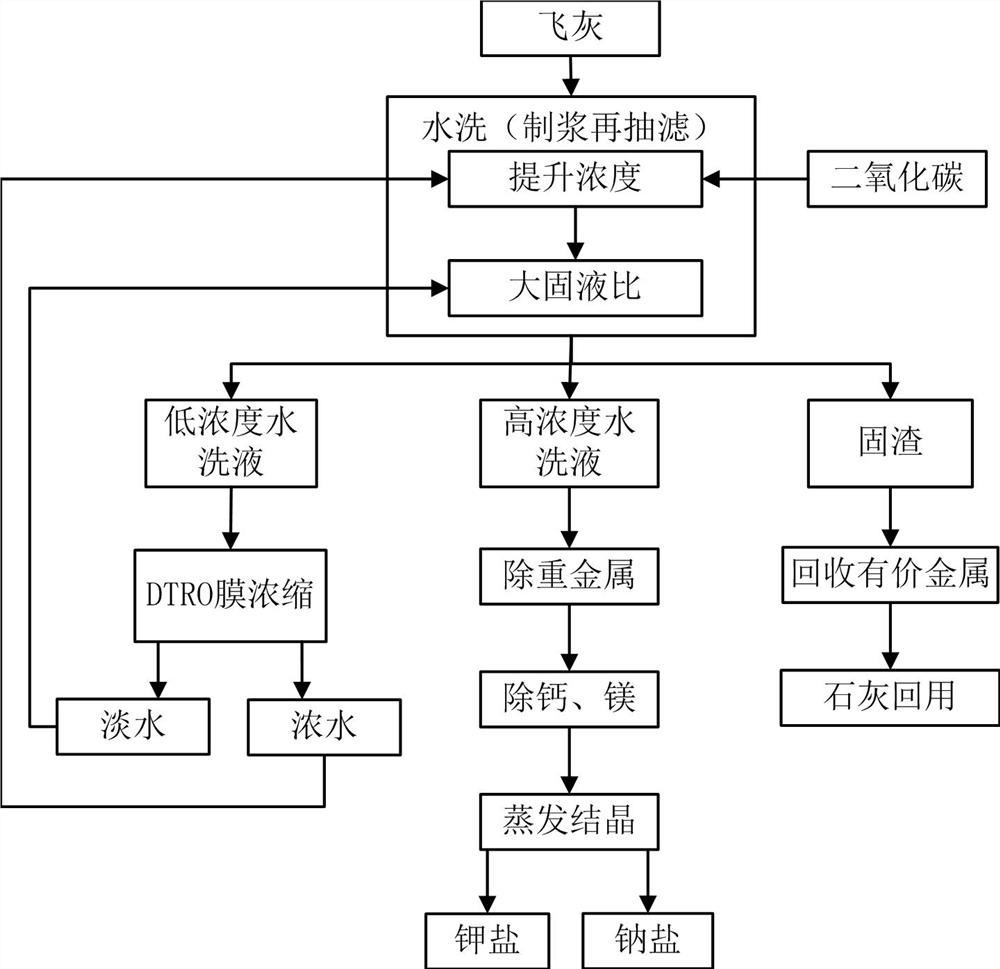

[0027] Example 1, such as figure 2 As shown, it includes the following steps:

[0028] Step 1. Mix fly ash and water according to the solid-to-liquid ratio of 1:3 to prepare a slurry, and at the same time, pass carbon dioxide gas into the slurry to adjust the pH value to 6;

[0029] Step 2, using a suction filter to filter the slurry prepared in step 1 to obtain high-concentration washing liquid and solid residue;

[0030] Step 3, mixing the solid slag obtained in the previous step with water according to a solid-to-liquid ratio of 1:3 to prepare a slurry;

[0031] Step 4, use a suction filter to filter the slurry prepared in step 3 to obtain high-concentration washing liquid and solid residue;

[0032] Step 5, mixing the solid slag obtained in the previous step with water according to a solid-to-liquid ratio of 1:3 to prepare a slurry;

[0033] Step 6, use a suction filter to suction filter the slurry obtained in step 5 to obtain high-concentration washing liquid and soli...

Embodiment 2

[0037] Example 2, such as figure 2 As shown, it includes the following steps:

[0038] Step 1. Mix fly ash and water according to the solid-to-liquid ratio of 1:4 to prepare a slurry, and at the same time, pass carbon dioxide gas into the slurry to adjust the pH value to 7;

[0039] Step 2, using a suction filter to filter the slurry prepared in step 1 to obtain high-concentration washing liquid and solid residue;

[0040] Step 3, mixing the solid slag obtained in the previous step with water according to a solid-to-liquid ratio of 1:4 to prepare a slurry;

[0041] Step 4, use a suction filter to filter the slurry prepared in step 3 to obtain high-concentration washing liquid and solid residue;

[0042] Step 5, mixing the solid slag obtained in the previous step with water according to a solid-to-liquid ratio of 1:4 to prepare a slurry;

[0043] Step 6, use a suction filter to suction filter the slurry obtained in step 5 to obtain high-concentration washing liquid and solid ...

Embodiment 3

[0047] Embodiment 3, it comprises the steps:

[0048] Step 1. Mix fly ash and water according to the solid-to-liquid ratio of 1:5 to prepare a slurry, and at the same time, pass carbon dioxide gas into the slurry to adjust the pH value to 8;

[0049] Step 2, using a suction filter to filter the slurry prepared in step 1 to obtain high-concentration washing liquid and solid residue;

[0050] Step 3, mixing the solid slag obtained in the previous step with water at a solid-to-liquid ratio of 1:5 to prepare a slurry;

[0051] Step 4, use a suction filter to filter the slurry prepared in step 3 to obtain high-concentration washing liquid and solid residue;

[0052] Step 5, mixing the solid slag obtained in the previous step with water at a solid-to-liquid ratio of 1:5 to prepare a slurry;

[0053] Step 6, use a suction filter to suction filter the slurry obtained in step 5 to obtain high-concentration washing liquid and solid residue;

[0054] Step 7, mixing the solid slag obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com