A kind of deep dehydration method of municipal sludge

A technology of municipal sludge and deep dewatering, applied in biological sludge treatment, dewatering/drying/concentrating sludge treatment, etc. The increase in the proportion of inorganic substances in the cake has achieved the effect of facilitating subsequent resource utilization, mild reaction, and low risk of secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (in the dehydration process, the ratio of sulfur powder and pyrite powder and the research on the input amount of inoculum)

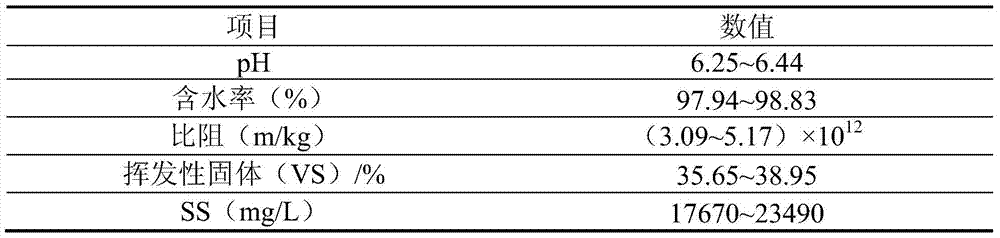

[0028] The sludge used in this experiment was taken from the residual sludge in the secondary sedimentation tank of a certain urban sewage plant, and its basic properties are shown in Table 1.

[0029] Table 1 Basic properties of the tested sludge

[0030]

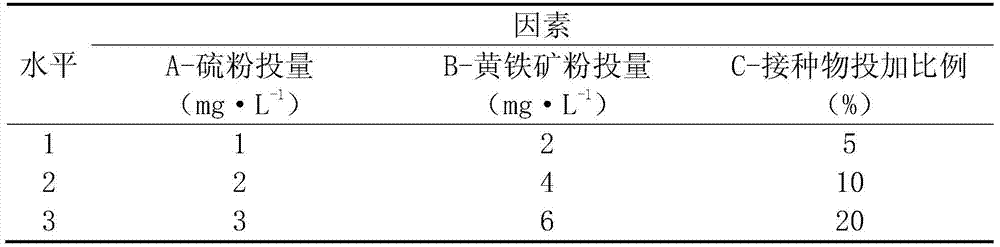

[0031] The orthogonal test factors and levels of this experiment are shown in Table 2.

[0032] Table 2 Orthogonal test factors and levels

[0033]

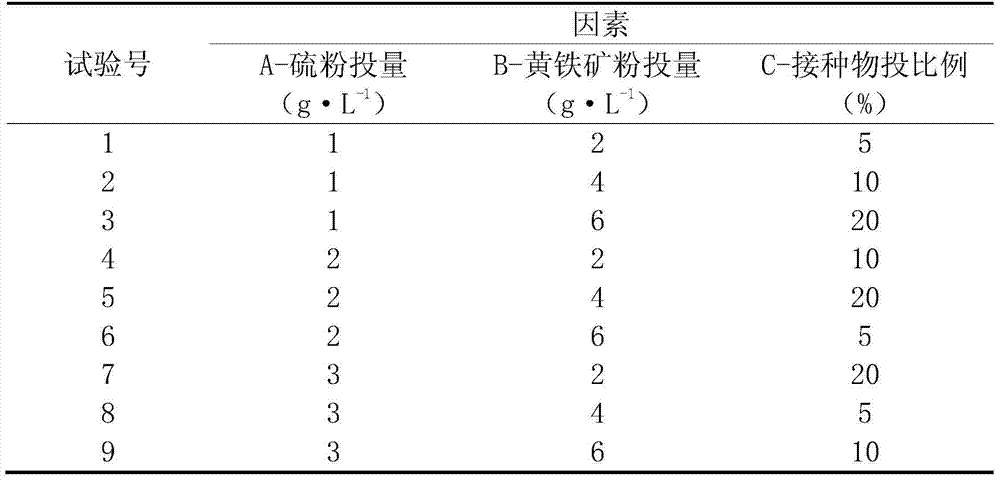

[0034] The scheme of this experiment is shown in Table 3.

[0035] Table 3 Orthogonal experiment design scheme

[0036]

[0037] The specific process of the above nine test programs is as follows:

[0038] (1) Take 150mL of the test sludge with the properties shown in Table 1, add 1.5g of sulfur powder and 1.5g of pyrite powder respectively, place it in a water bath shaker at a speed of 180r / min, and shake the flask at ...

Embodiment 2

[0049] 1. The sludge to be tested is taken from the residual sludge in the primary sedimentation tank of a sewage plant, and its basic properties are shown in Table 6.

[0050] Table 6 Basic properties of test sludge (residual sludge in primary sedimentation tank)

[0051]

[0052] 2. Dehydration treatment

[0053] (1) Take 150mL of the test sludge with the properties shown in Table 6, add 1.5g of sulfur powder and 1.5g of pyrite powder respectively, place it in a water bath shaker and shake the flask at a constant temperature of 28°C at a speed of 180r / min Cultivate; when the pH value of the sludge system is 2.5, end the first cultivation, and obtain the 20mL culture; then, add 130mL of the test sludge with the properties shown in Table 6 to the first culture, and use the same Conditions carry out secondary shake flask culture; Finally, add 6.5 volumes of the test sludge of the character shown in Table 6 to the culture for the second time and repeat the shake flask culture ...

Embodiment 3

[0059] The sludge to be tested was taken from the residual sludge in the secondary settling tank of a sewage plant, which adopted the improved A 2 / O process, no chemicals were added during the treatment process. The basic properties of the above sludge are shown in Table 7.

[0060] Table 7 Basic properties of the test sludge (residual sludge in the secondary settling tank)

[0061]

[0062] 2. Dehydration treatment

[0063] (1) Take 150mL of the test sludge with the properties shown in Table 7, add 1.5g of sulfur powder and 1.5g of pyrite powder respectively, and shake the flask in a water bath shaker at a constant temperature of 28°C at a speed of 180r / min Cultivate; when the pH value of the sludge system is 2.5, end the first cultivation, and obtain the 20mL culture; then, add 130mL of the test sludge with the properties shown in Table 7 to the first culture, and use the same Conditions carry out secondary shake flask culture; Finally, add 6.5 volumes of the test slu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com