System and method for drying municipal sludge by utilizing slag dryer of coal-fired boiler of power station

A technology for coal-fired boilers and municipal sludge, applied in combustion methods, dryers, sludge drying, etc., can solve problems such as low practicability, increased ash content, blockage of raw coal bunkers, etc., and achieve improved drying efficiency and smoke exhaust The effect of lowering the temperature and increasing the heat transfer temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make those skilled in the art better understand the technical solutions of the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

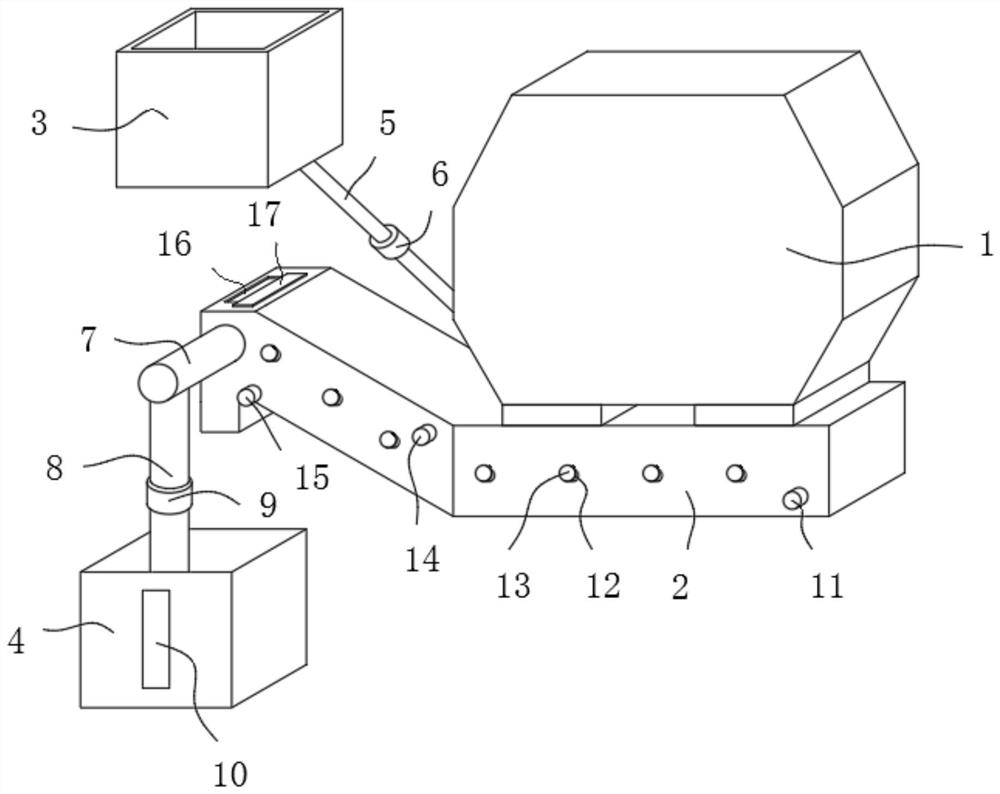

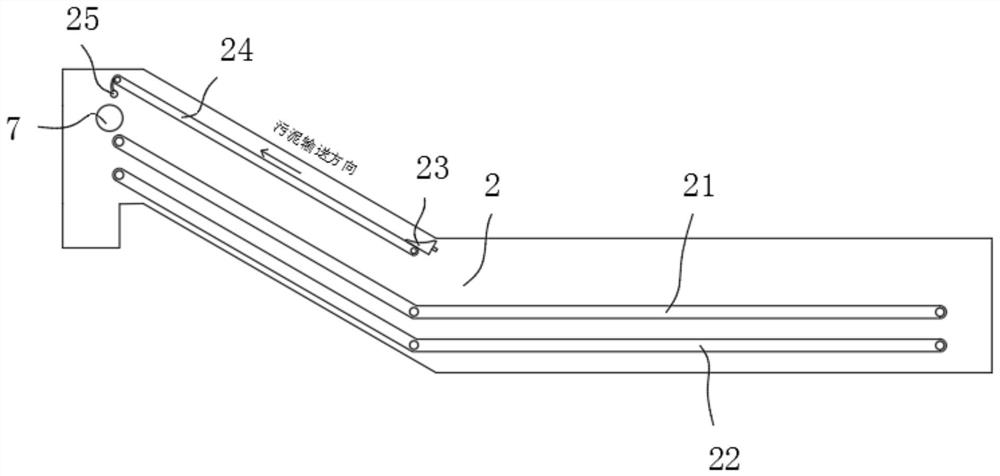

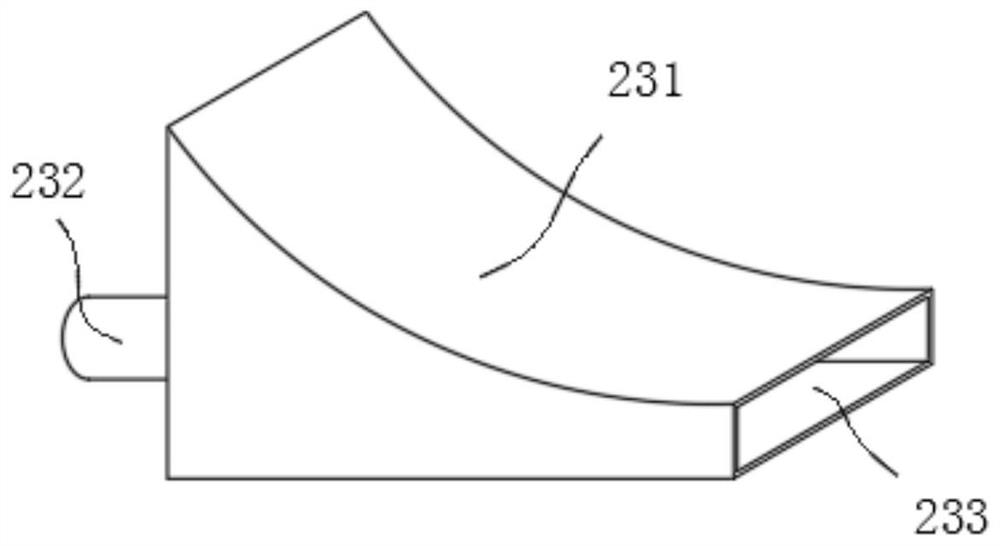

[0054] like Figure 1-Figure 4 As shown in the figure, a system for drying urban sludge using a coal-fired boiler slag dryer of a power station includes a boiler 1 and a slag dryer 2. The slag dryer 2 includes a horizontal section and an inclined section, and the slag dryer 2 is internally provided with a system for conveying slag. The feed port of the horizontal section of the slag machine 2 is located directly below the slag discharge port of the boiler 1. The negative pressure in the boiler 1 sucks the air from the air inlet damper 16 at the upper end of the inclined section of the slag machine 2. After falling into the horizontal section of the slag conveying assembly, it is sent to the slag storage chamber at the end of the slag dryer 2 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com