Spiral rising arrangement mode of blades

A technology of helical rise and paddle, applied to mixers with rotating stirring devices, chemical instruments and methods, dissolution, etc., can solve problems such as high energy consumption, poor mixing, and too many layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

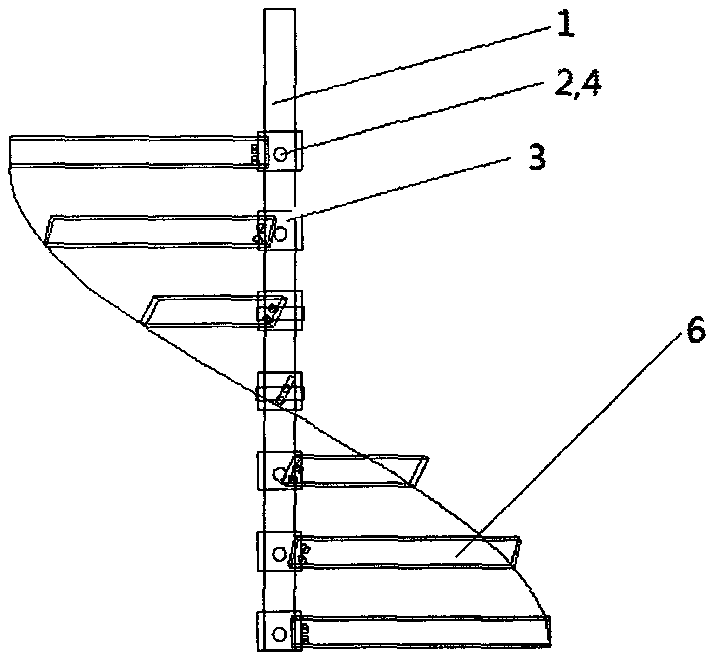

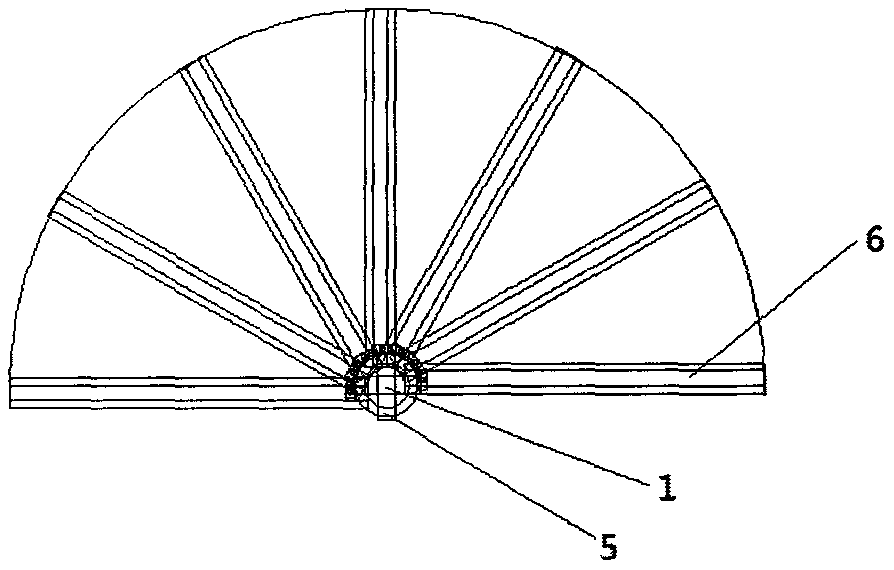

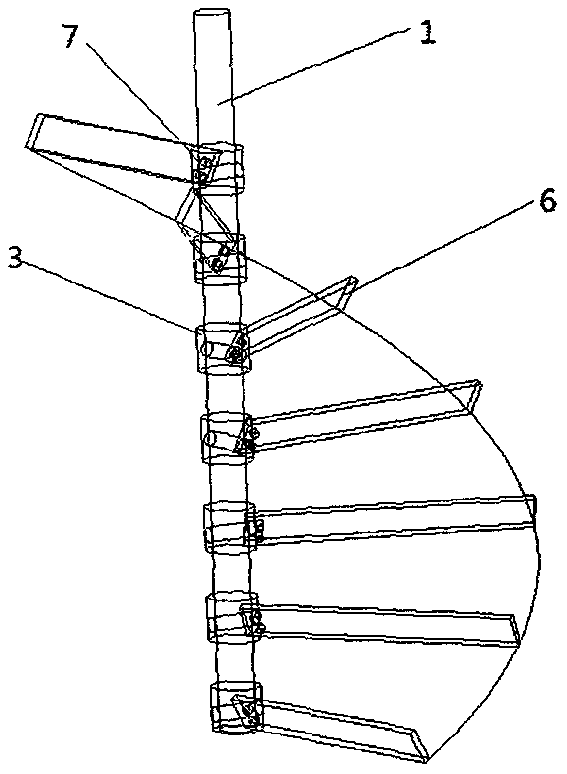

[0018] The present invention proposes an arrangement mode in which blades spirally rise. In this arrangement, the paddles rise clockwise or counterclockwise along the stirring shaft, and when they rotate in the stirring tank, it is improved in the past for stirring tanks with large height-to-diameter ratios, only multi-layer paddles can be used, and the multi-layer paddles There is a defect of poor agitation effect between layers. At the same time, it is also realized that the position of the stirring shaft is fixed, but the stirring effect is like the effect of a single-layer paddle rising or falling while rotating. This design method reduces the complexity of mechanical design and operation.

[0019] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0020] Such as Figure 1-Figure 3 As shown in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com