MTBE product desulfurization device

A desulfurization device and product technology, applied in distillation separation, organic chemistry, fractionation, etc., can solve the problems of small investment, affecting MTBE yield, MTBE loss, etc., achieve high energy utilization rate, reduce desulfurization cost, and improve desulfurization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

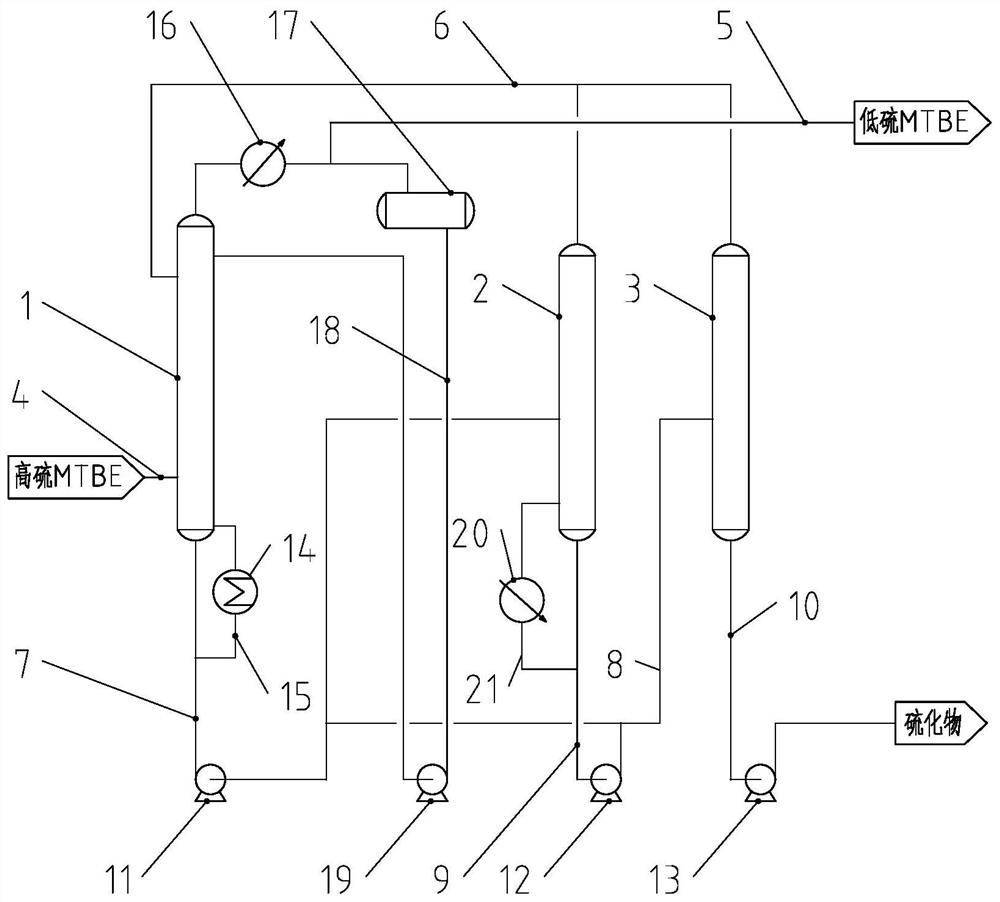

[0036] Such as figure 1 A kind of MTBE product desulfurization device shown includes distillation tower 1, stripping tower 2, auxiliary tower 3 and connecting pipeline network, and connecting pipeline network includes high-sulfur MTBE feed pipeline 4, low-sulfur MTBE discharge pipeline 5. The first circulation pipeline 6 , the first discharge pipeline 7 , the first discharge branch 8 , the second discharge pipeline 9 and the third discharge pipeline 10 . The high-sulfur MTBE feed pipeline 4 is connected to the middle of the distillation tower 1, the low-sulfur MTBE discharge pipeline 5 is connected to the top of the distillation tower 1, and the first circulation pipeline 6 is connected to the upper part of the distillation tower 1, the top of the stripping tower 2 and the top of the auxiliary tower 3 , the first discharge pipeline 7 is connected to the bottom of the distillation tower 1 and the middle part of the stripper 2, the first discharge branch 8 is connected to the fi...

Embodiment 2

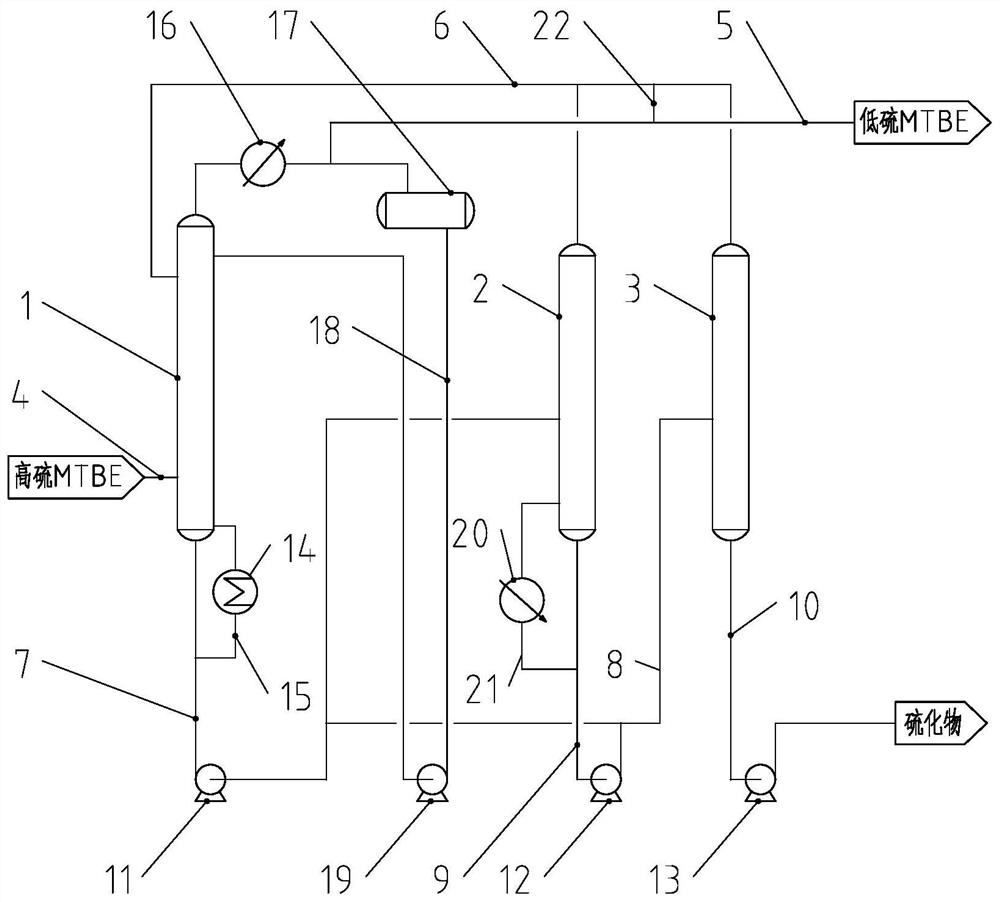

[0042] Such as figure 2A kind of MTBE product desulfurization device shown includes distillation tower 1, stripping tower 2, auxiliary tower 3 and connecting pipeline network, and connecting pipeline network includes high-sulfur MTBE feed pipeline 4, low-sulfur MTBE discharge pipeline 5. The first circulation pipeline 6 , the first discharge pipeline 7 , the first discharge branch 8 , the second discharge pipeline 9 and the third discharge pipeline 10 . The high-sulfur MTBE feed pipeline 4 is connected to the middle of the distillation tower 1, the low-sulfur MTBE discharge pipeline 5 is connected to the top of the distillation tower 1, and the first circulation pipeline 6 is connected to the upper part of the distillation tower 1, the top of the stripping tower 2 and the top of the auxiliary tower 3 , the low-sulfur MTBE discharge pipeline 5 is provided with a low-sulfur MTBE return branch 22 , and the low-sulfur MTBE return branch 22 connects the low-sulfur MTBE discharge p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com