Anti-blocking desalting device and method

A desalination device and anti-clogging technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. The effect of blocking, efficient desalination, and raising the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

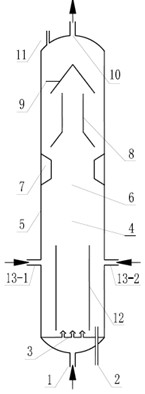

[0035] Adopt the present invention to attach figure 1 The desalination device shown is the same as that in Embodiment 1. In the high-salt organic wastewater, the COD concentration is 92600mg / L, the TDS is 13.5wt%, and the pH is 8.5.

[0036] Pass high-salt organic wastewater (at normal temperature and pressure at 30MPa) and oxygen (at normal temperature and at pressure at 30MPa) into the desalination device, in which the solid particles in the desalination device are alumina ceramic balls with a diameter of 0.4mm. Density 0.65g / cm 3 , the specific surface area is 260m 2 / g, the amount of solid particles added is 1 / 2 of the volume of the device. The amount of oxygen introduced is 300% of the theoretical oxygen demand for wastewater oxidation. The operating temperature of the inner chamber of the device is 600° C., the pressure is 28 MPa, and the residence time is 30 seconds. The amount of solid particles added and discharged is 75g•h -1 • L -1 Ingress of water. After tr...

Embodiment 2

[0038] Same as Example 1, the difference is that the solid particles are made of silica pellets with a diameter of 0.5mm and a specific surface area of 230m 2 / g. After treatment, the COD concentration in the effluent water is 53mg / L, and the TDS is 62mg / L. After 100 days of continuous operation, neither the device nor the pipeline was blocked.

Embodiment 3

[0040] The same as in Example 1, the difference is that sodium hydroxide is added to the high-salt wastewater fed, and the pH of the feed water is controlled to be 11. After treatment, the COD and TDS in the effluent did not change much. However, the pH value of the influent is controlled to be alkaline, and the alkaline substances in the wastewater can neutralize the acidic substances generated during the desalination process, thereby avoiding corrosion of the device. After 100 days of continuous operation, neither the device nor the pipeline was blocked.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com