Train-network model construction method for joint type electric segmental arcing of anchoring section of train

A construction method and electric segmentation technology, applied in power lines, vehicle components, design optimization/simulation, etc., can solve problems such as burning contact wires and pantograph bowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] A method for constructing a car-network model of the joint-type electric segmental arcing of a train passing through the anchor section of the present invention, the specific steps are:

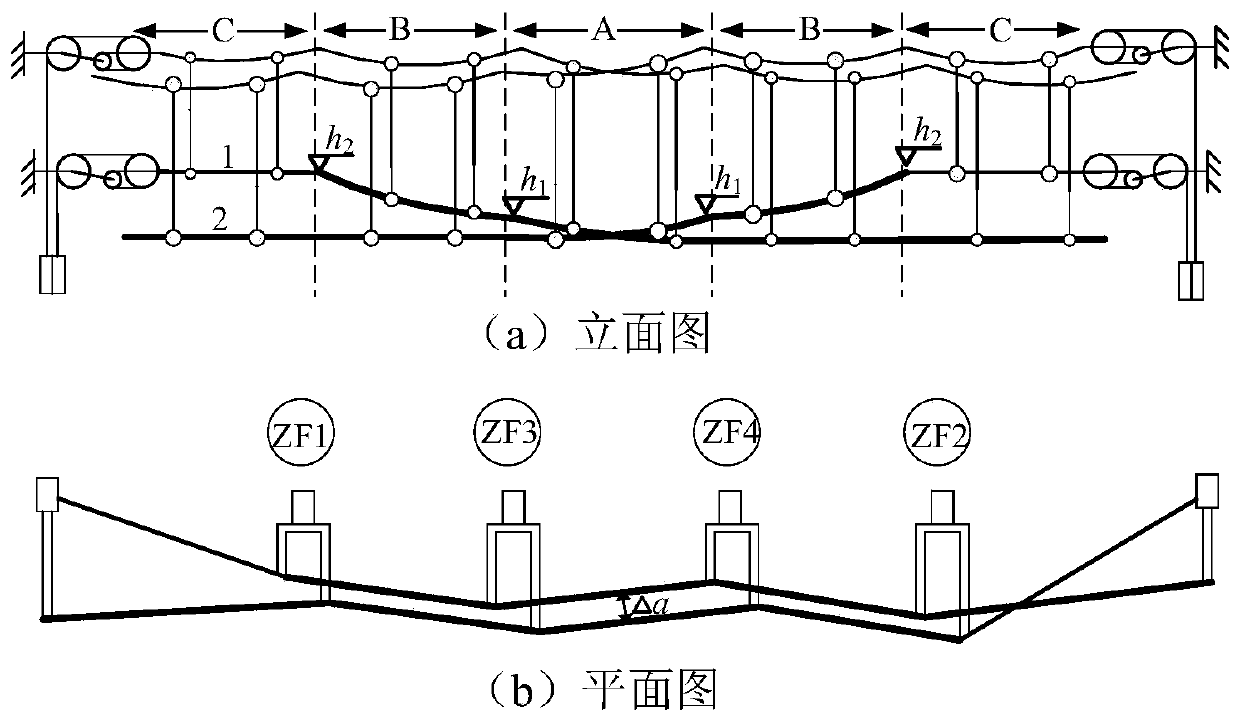

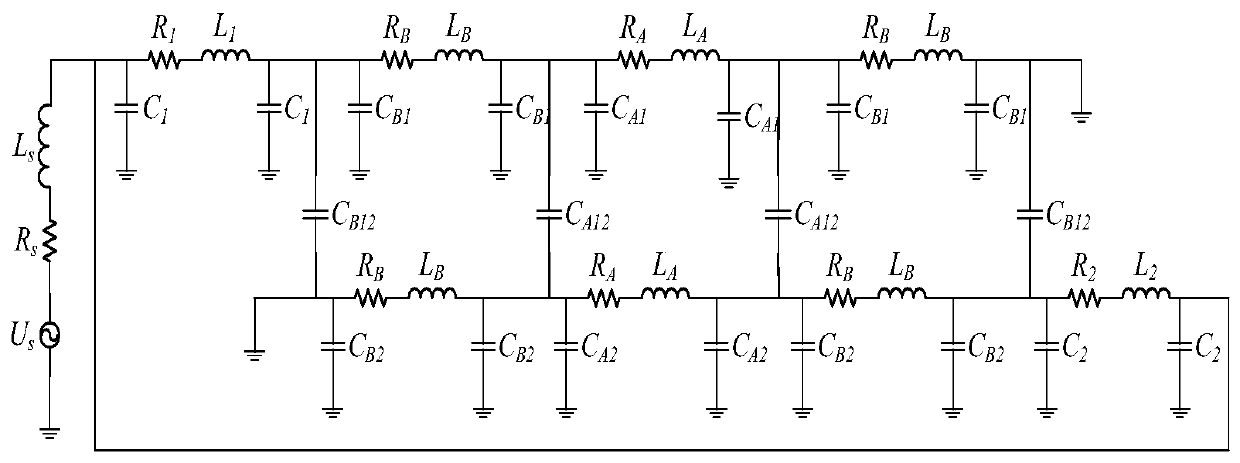

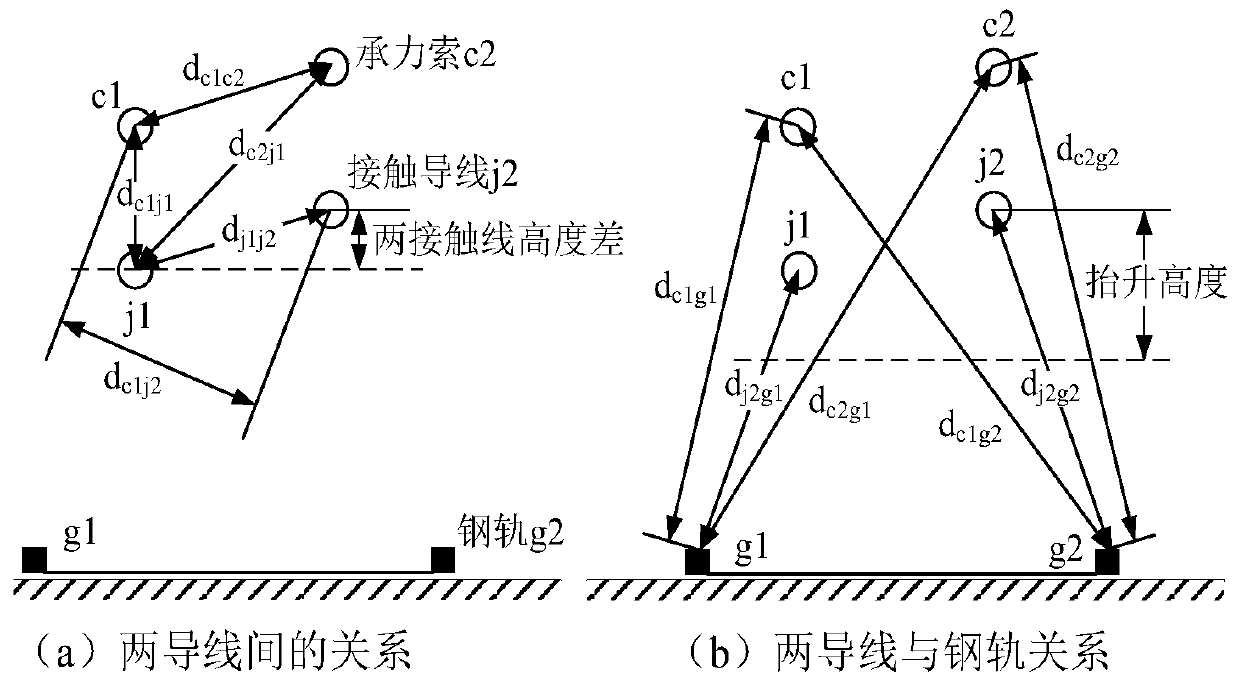

[0024] 1. Circuit modeling of the traction network system including the articulated electric segment of the anchor segment

[0025] attached figure 1 It is the actual installation diagram of the articulated electric segmental contact suspension of a five-span anchor section of a high-speed railway with a speed of 250 kilometers per hour in my country. Among them, ZF1, ZF2, ZF3, and ZF4 are the conversion columns, h1 and h2 are the vertical distances between the two contact lines at the conversion columns, and Δα is the horizontal distance between the two wires. Divide the electrical segment into three segments A, B, and C to establish an equivalent circuit model of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com