High-voltage gas circuit breaker breaking performance evaluation method and system

A high-voltage gas circuit breaker technology, applied in the field of power electronics, can solve the problem of comprehensive evaluation of thermal breakdown and electrical breakdown characteristics of high-voltage gas circuit breakers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

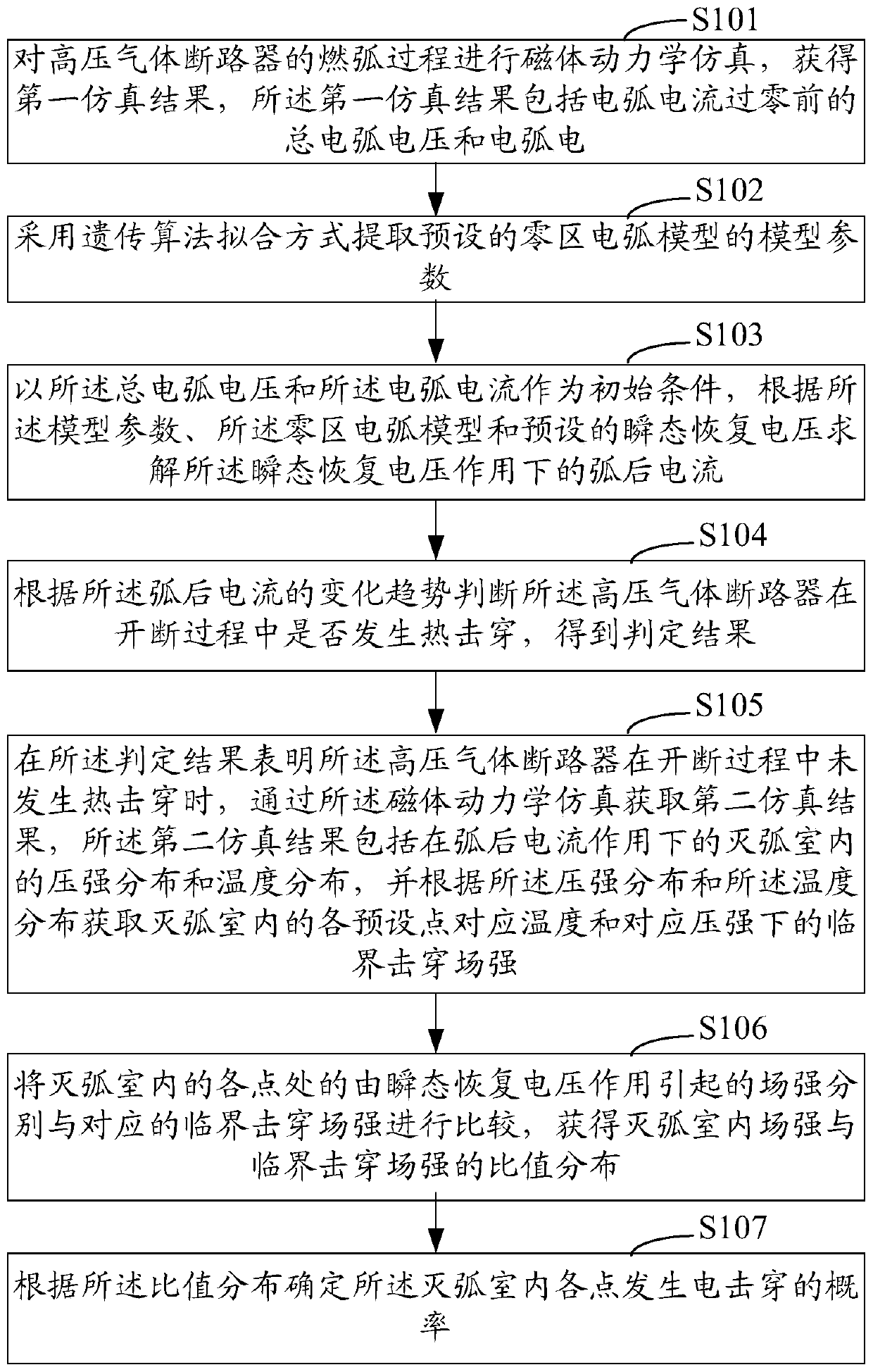

[0035] Embodiment 1 of the present invention provides a method for evaluating the breaking performance of a high-voltage gas circuit breaker. see figure 1 As shown in FIG. 1 , it is a schematic flowchart of the implementation of the method for evaluating the breaking performance of a high-pressure gas circuit breaker in Embodiment 1 of the present invention. Such as figure 1 As shown, the method for evaluating the breaking performance of a high-voltage gas circuit breaker in this embodiment includes the following steps:

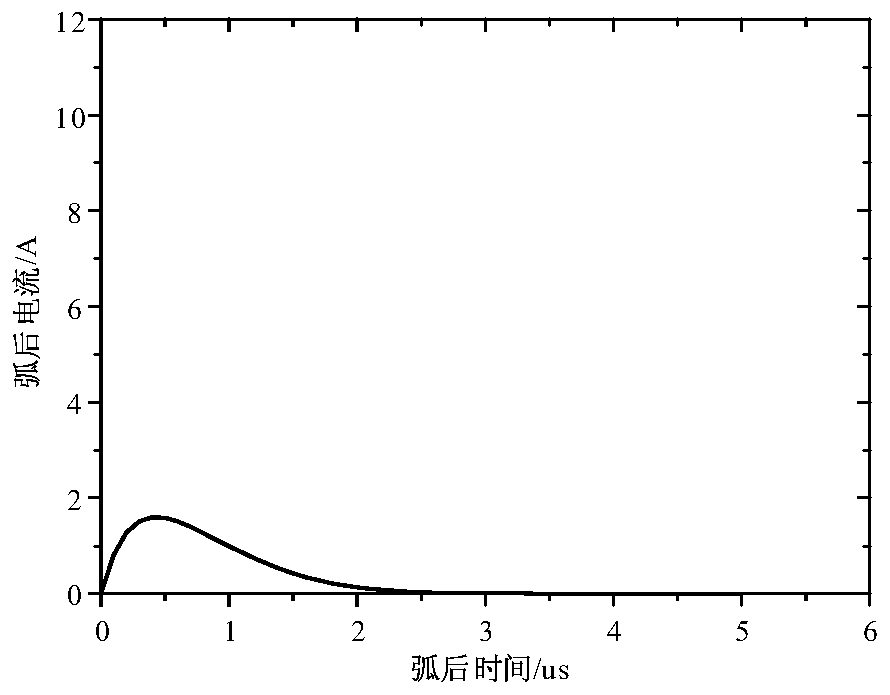

[0036] Step S101: Perform magnet dynamics simulation on the arcing process of the high-voltage gas circuit breaker to obtain a first simulation result, the first simulation result including the total arc voltage and arc current before the arc current crosses zero;

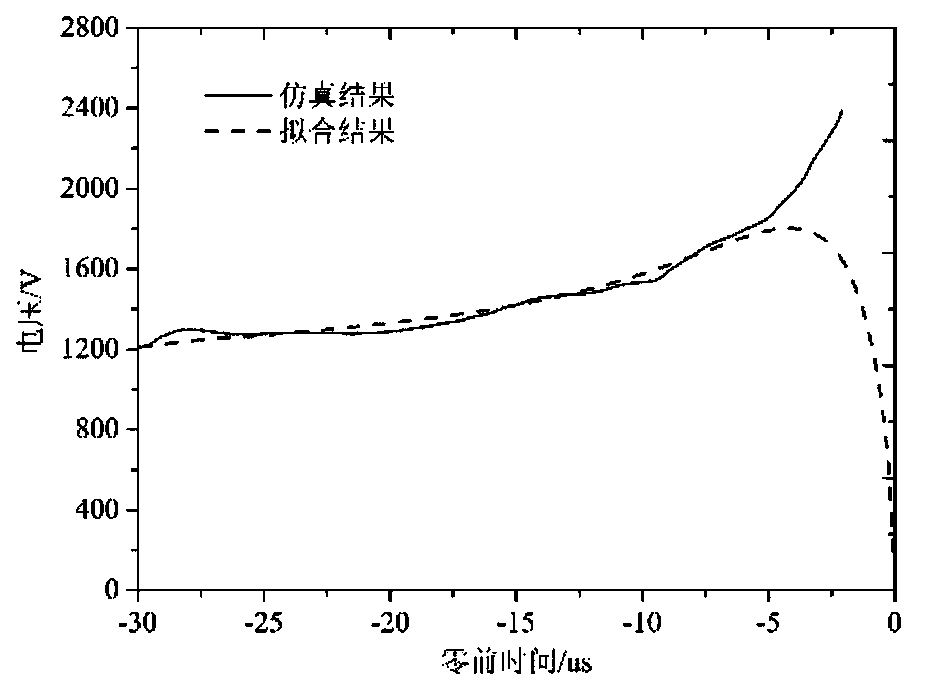

[0037] Considering the symmetry of the high-voltage circuit breaker structure, a two-dimensional axisymmetric arc model can be used to simulate the arc for magnet dynamics. The control equation ...

Embodiment 2

[0071] According to the method for evaluating the breaking performance of the high-voltage gas circuit breaker in the above embodiments, the present invention further provides a system for evaluating the breaking performance of the high-voltage gas circuit breaker. Figure 9 It is a schematic diagram of the composition and structure of the high-voltage gas circuit breaker breaking performance evaluation system according to the second embodiment of the present invention. Figure 9 A schematic diagram of a preferred composition structure of the high-voltage gas circuit breaker breaking performance evaluation system according to Embodiment 2 of the present invention is shown in . According to different consideration factors, when implementing the high-voltage gas circuit breaker breaking performance evaluation system of the present invention, it can include Figure 9 All shown in , or just the Figure 9 Some of them shown in , the following will describe in detail the specific e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com