Curved test piece making device for hydraulic model

A technology for hydraulic model and production device, applied in hydraulic model and other directions, can solve the problems of lack of simulation effect, low precision, time-consuming and labor-intensive, etc., and achieve the effects of good stability, high control precision and accurate simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

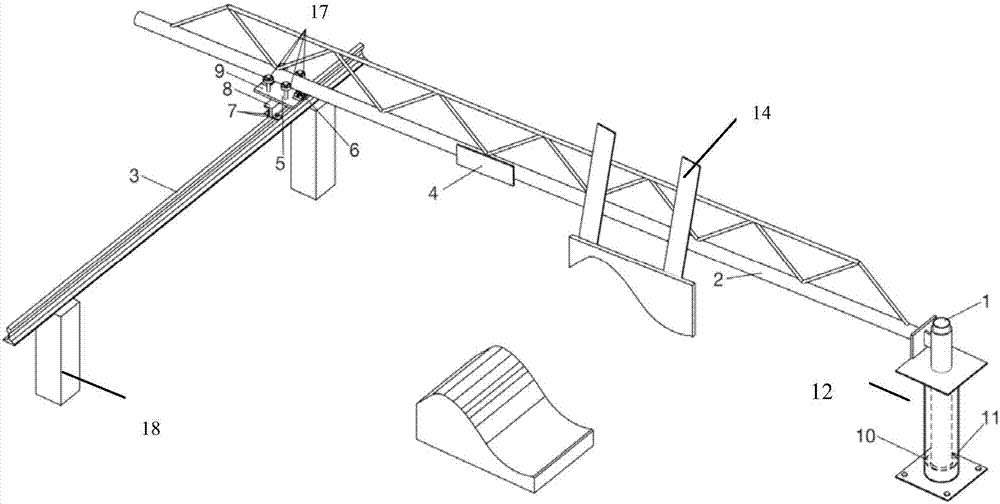

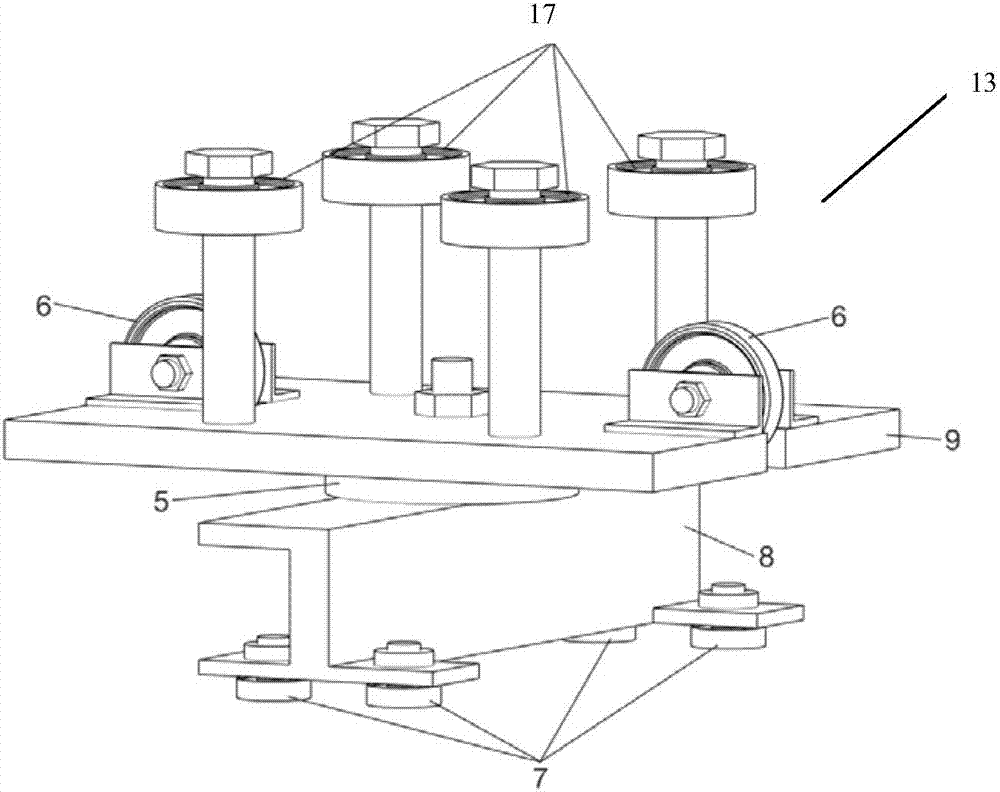

[0014] Such as figure 1 , 2 As shown, the arc test piece manufacturing device for hydraulic model of the present invention includes a horizontally arranged slide bar 2, a support 18 with a horizontal steel beam guide rail 3 and a support 12 with a vertical rotating shaft 1, A slide trolley 13 capable of sliding along the steel beam guide rail 3 is installed on the bracket 18 with the steel beam guide rail. , as the slideway trolley 13 slides on the steel beam guide rail 3, the sliding rod 2 can be adjusted at any time to insert the length of the slideway trolley 13, so that the sliding rod 2 follows the movement of the slideway trolley 13 along the steel beam guide rail 3 with the rotating shaft 1 as the center While rotating, a scraper 14 matching the arc-shaped test piece is fixed at the middle position of the slide bar 2 .

[0015] Describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com