Small-spacing BGA automatic wire outgoing method and device

A small-pitch, automatic technology, applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of long design cycle, complicated wiring methods, and low design efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

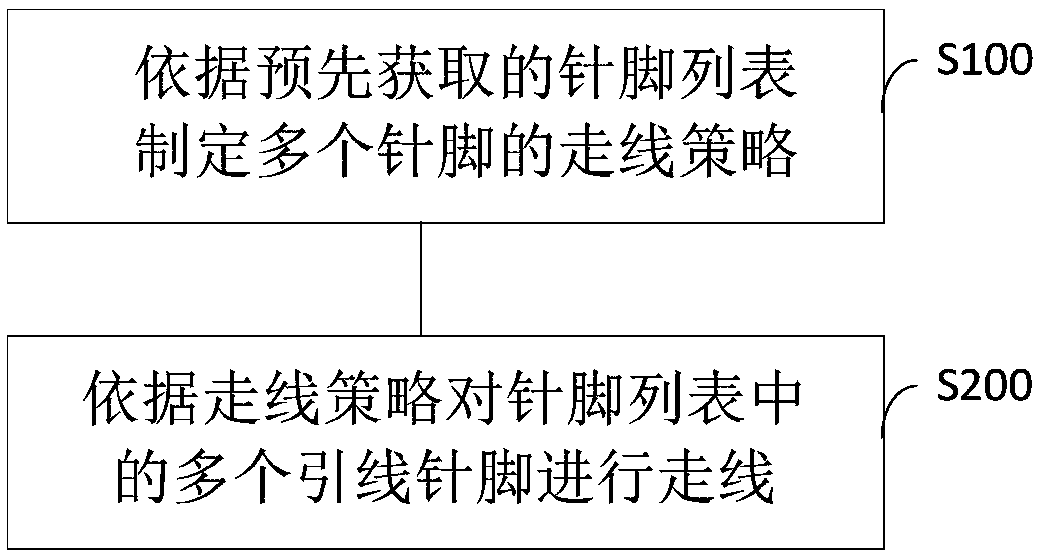

[0065] see figure 1 , this embodiment provides an automatic wiring method for small-pitch BGAs. The automatic wiring method for small-pitch BGAs provided by this embodiment can shorten the design cycle, reduce labor costs, and improve wiring efficiency.

[0066] The small-pitch BGA automatic wire-out method provided in this embodiment is mainly used for BGAs below 0.8 mm, which can ensure that small-pitch BGAs can be wire-out normally, shorten the design cycle, reduce labor costs, and improve wire-out efficiency.

[0067] Specific steps are as follows:

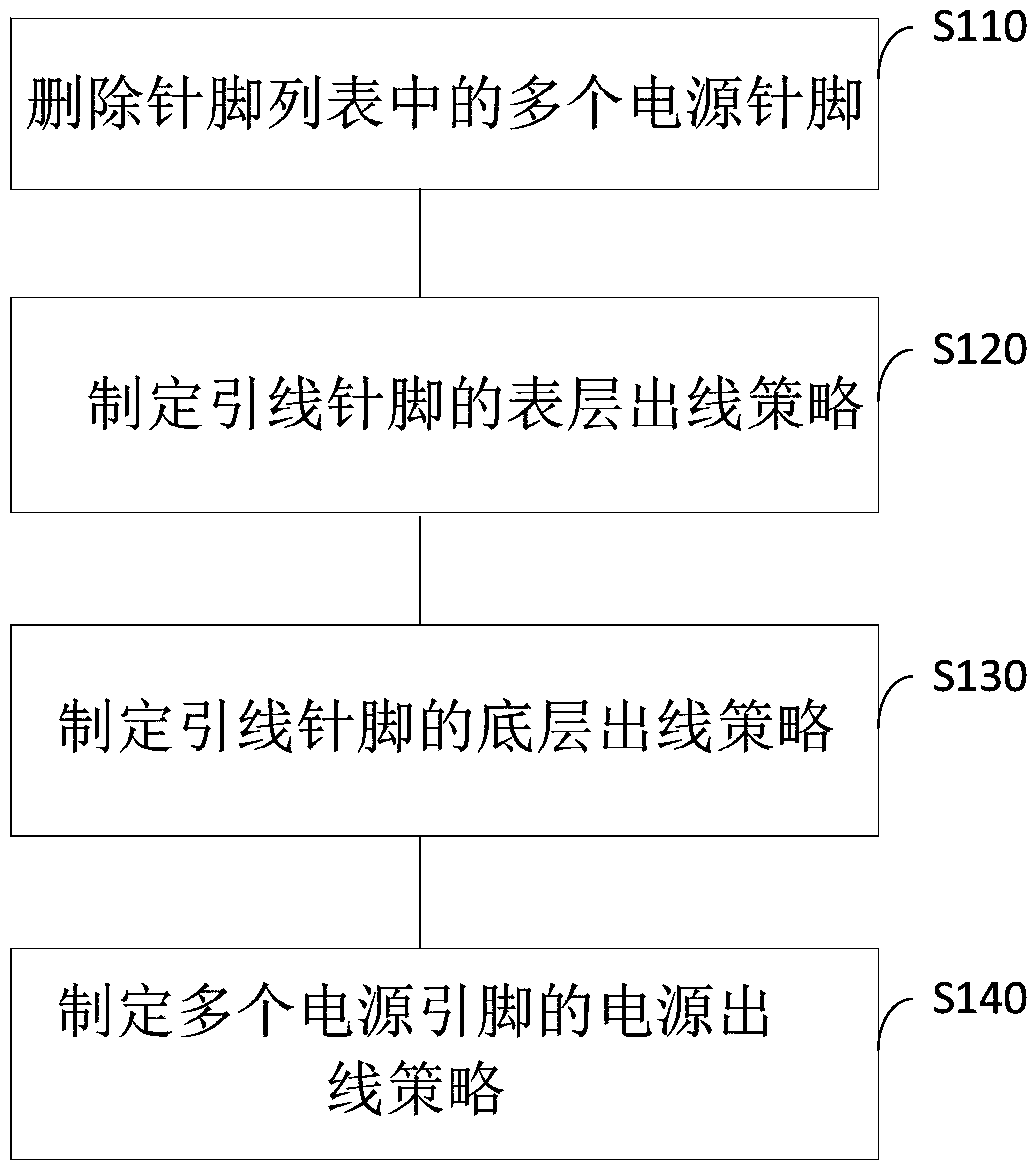

[0068] see figure 1 , step S100 , formulate routing strategies for multiple pins according to the pre-acquired pin list. Wherein, the pins include lead pins and power pins.

[0069] In this embodiment, the pin list of the BGA is obtained first, and the routing strategy for the pins in the pin list is formulated according to the pin list of the BGA.

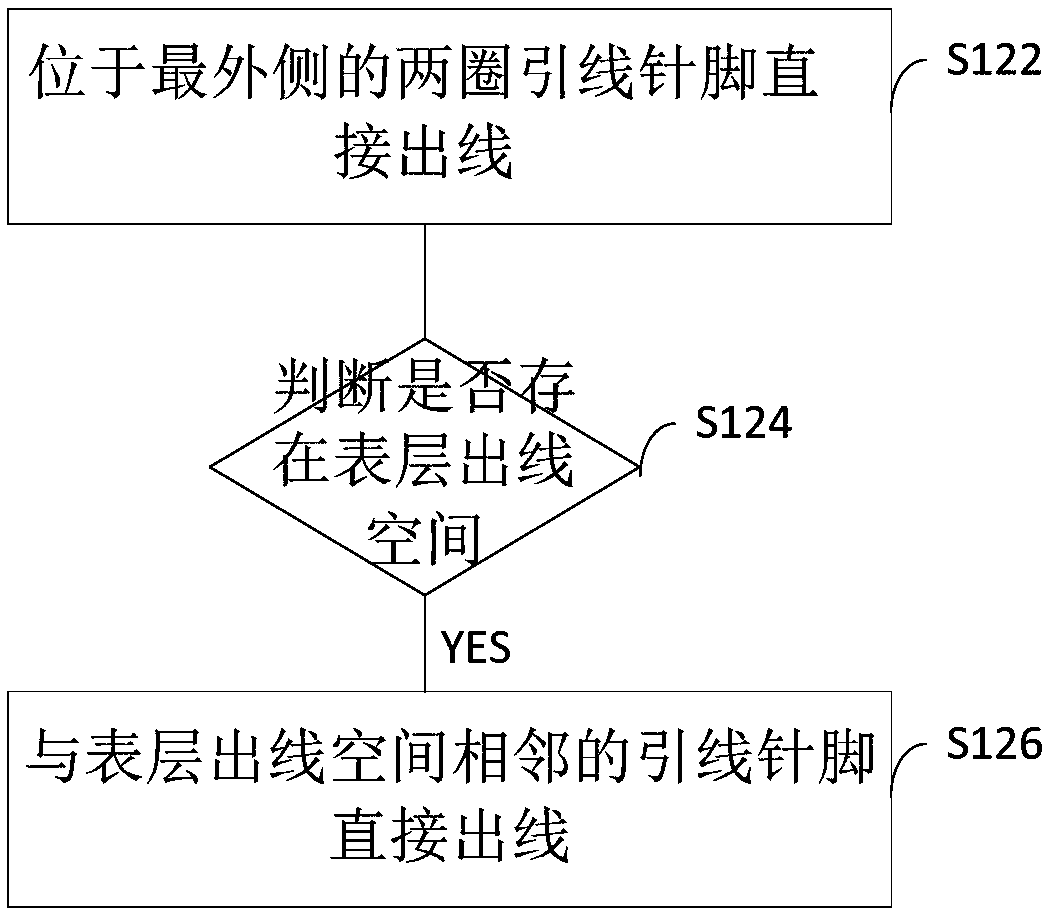

[0070] In this embodiment, before formulating the routing strategy, the f...

Embodiment 2

[0114] see Figure 7 , this embodiment provides a small-pitch BGA automatic wiring device 10, the small-pitch BGA automatic wiring device 10 provided in this embodiment can shorten the design cycle, reduce labor costs, and improve wiring efficiency.

[0115] For a brief description, reference may be made to Embodiment 1 for parts not mentioned in this embodiment.

[0116] In the present invention, the small-pitch BGA automatic outlet device 10 includes:

[0117] The strategy module 100 is configured to formulate routing strategies for multiple stitches according to the pre-acquired stitch list.

[0118] In the embodiment of the present invention, step S100 may be executed by the policy module 100 .

[0119] The routing module 200 is configured to route a plurality of lead stitches in the stitch list according to the routing strategy, wherein the plurality of lead stitches are arranged in a matrix.

[0120] In the embodiment of the present invention, step S200 may be execute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com