Strong rear propelling tube bending control method of tube bending machine and system

A technology of pipe bending control and pipe bending machine, which is applied in the field of pipe bending machine's strong back-boosting pipe bending control. It can solve the problems of complex mechanical structure, poor boosting synchronization, unfavorable design and installation, etc., and achieve simple mechanical structure and strong versatility. Sexuality and convenience for technological transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

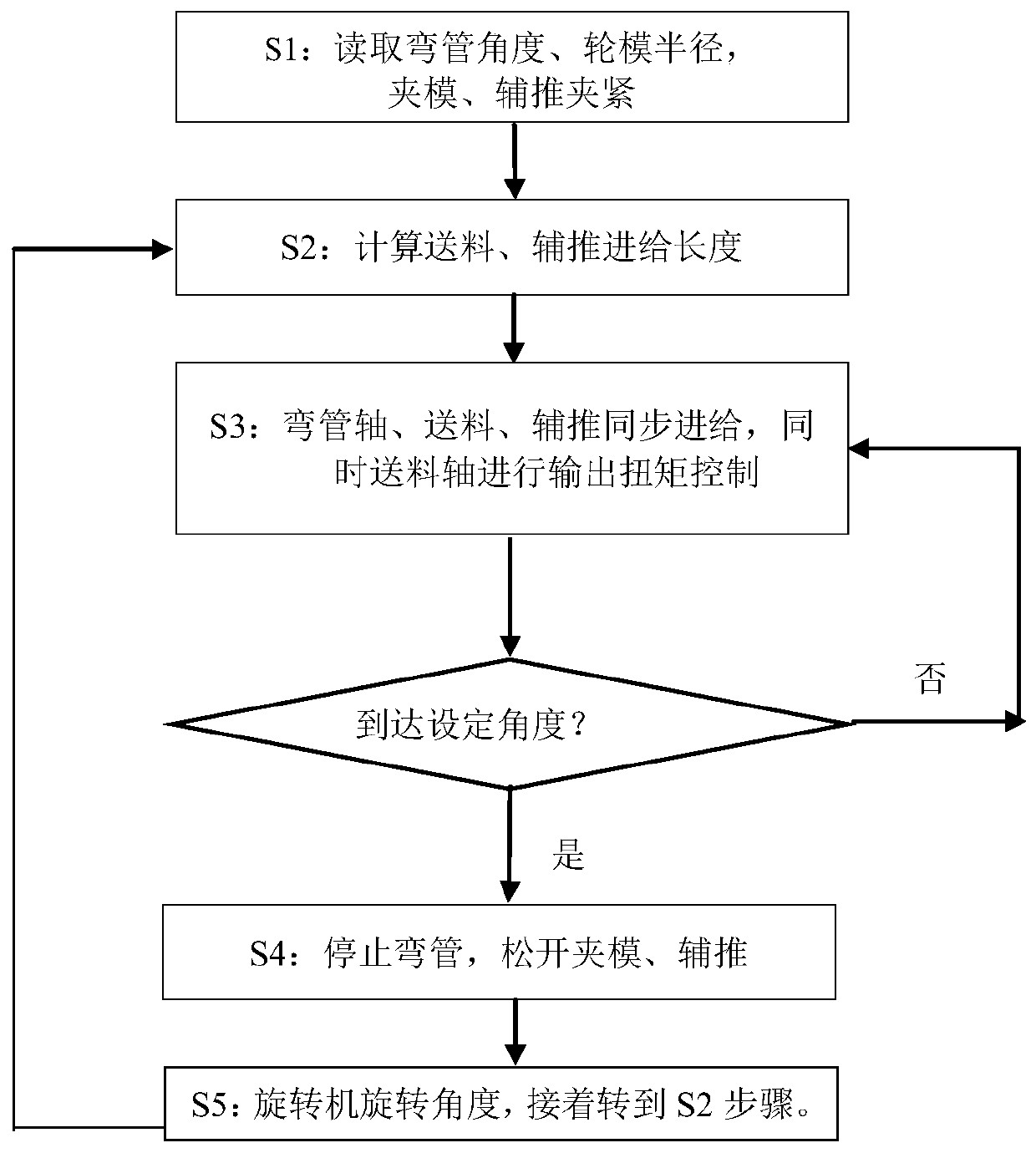

[0028] Such as figure 1 as shown, figure 1 It is a flow chart of Embodiment 1 of the present invention. Embodiment 1 of the present invention provides a method for controlling bending of a pipe bender after strong force, and the steps of the method are as follows:

[0029] S1: Read the angle of the elbow, clamp the mold, and push the auxiliary clamp;

[0030] The bending angle C, bending radius R and wheel mold radius are read by the pipe bending machine control system, and the pipe fittings are clamped by the clamping die and the auxiliary push shaft after loading;

[0031] S2: Calculate the feeding length and auxiliary feeding length;

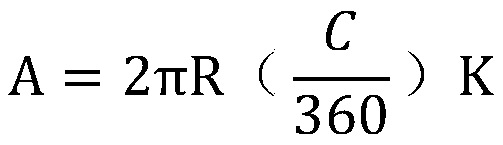

[0032] According to the elbow bending radius R and bending angle C technical parameters read by S1, the feeding feed length Y and auxiliary feed length F are calculated; the calculation method is as follows:

[0033] Known: bending radius R, bending angle C, coefficient K ranges from 0.8 to 1.2;

[0034] Suppose: the feeding length is Y, ...

Embodiment 2

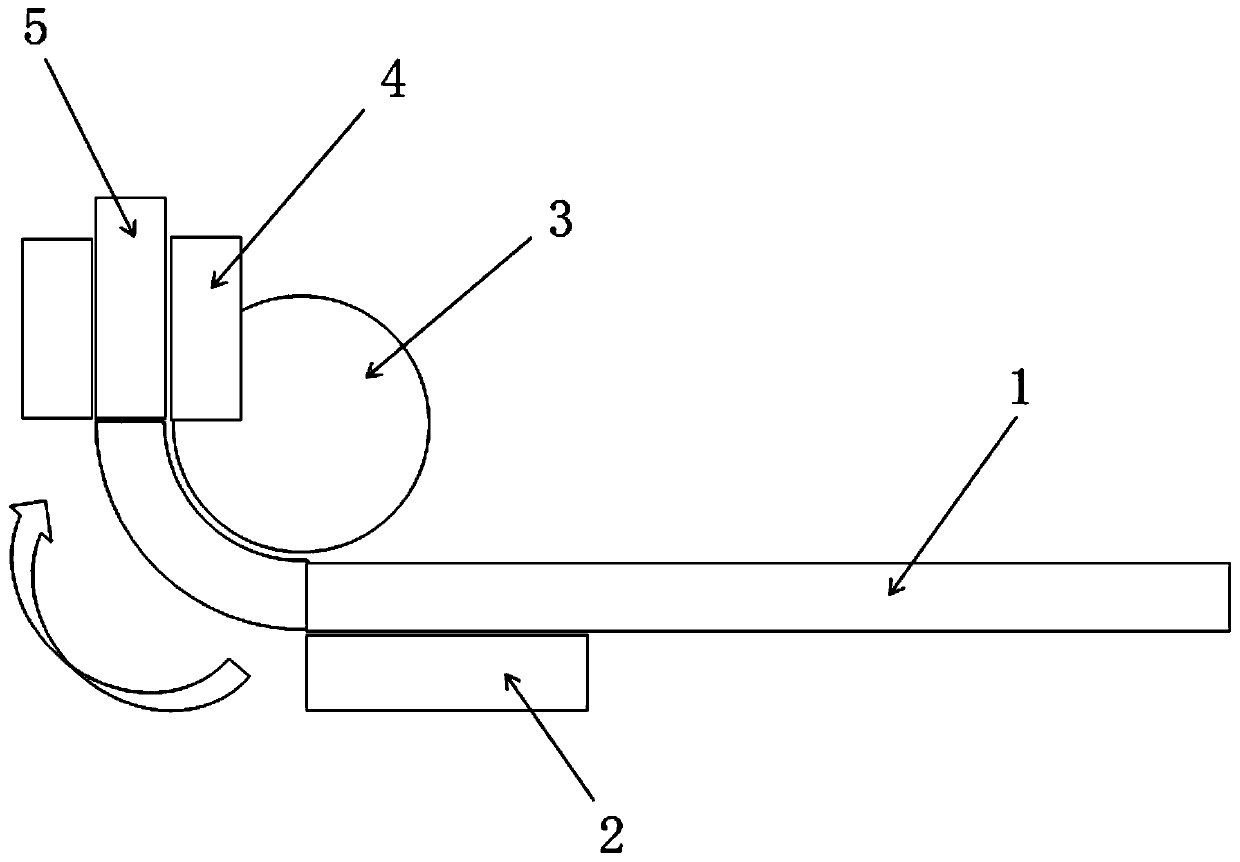

[0047] Such as figure 2 As shown, Embodiment 2 of the present invention also proposes a post-bend boost control system. The control system uses the powerful post-bend tube bend control method of the above-mentioned Embodiment 1 to achieve 1.5D small bending To meet the production requirements of curved pipes with a radius, the control system includes feeding shaft 1, auxiliary pushing shaft 2, wheel mold 3 and clamping die 4. One end of the pipe fitting 5 is clamped by the feeding shaft 1, and the other end is clamped by the clamping die 4. The auxiliary pushing shaft The shaft 2 is arranged outside the middle part of the pipe fitting 5, and the auxiliary pushing shaft 2 is close to the pipe fitting 5, and the figure 2 The direction of the arrow in the figure is the direction of the bent pipe, which is only for illustration and does not limit the present invention.

[0048] Through the implementation of Embodiment 2 and Embodiment 1, compared with the traditional bending mo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap