Automatic-blocking forging forming die

A forging forming and automatic blocking technology, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of small mold clamping force, flashing, overflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

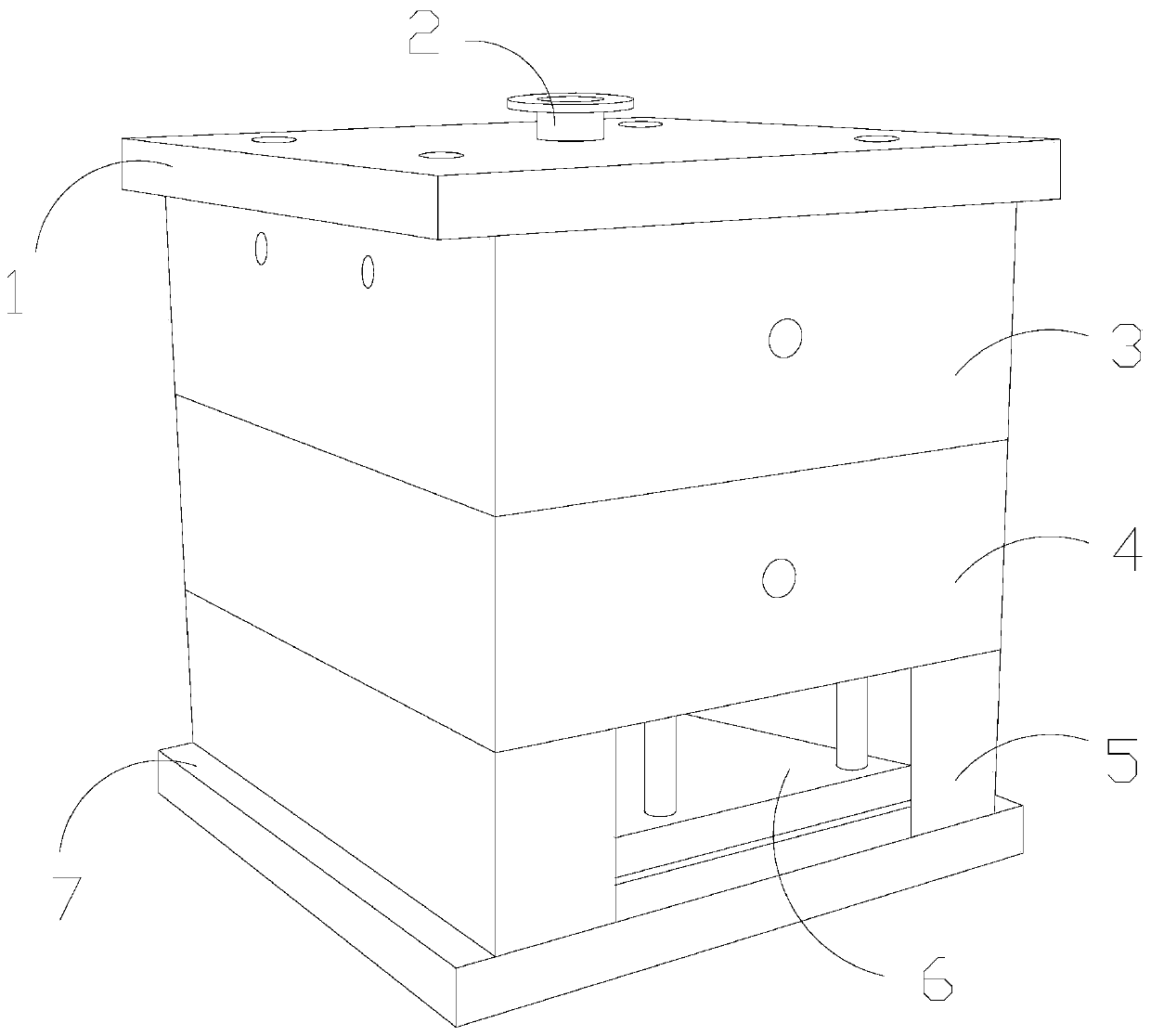

[0029] as attached figure 1 to attach Figure 7 Shown:

[0030] The present invention provides an automatic block forging molding die, the structure of which includes an upper top plate 1, an injection port 2, an upper template 3, a block lock control device 4, a lower template 5, a guide frame 6, and a bottom plate 7. The top of the upper top plate 1 There is an injection port 2 in the middle, the bottom end of the upper template 3 fits the top of the block lock control device 4, the block lock control device 4 is fixedly connected with the lower template 5, and the guide frame 6 is embedded in the The inside of the locking device 4 is blocked, and the bottom plate 7 is attached to the bottom plate 7 .

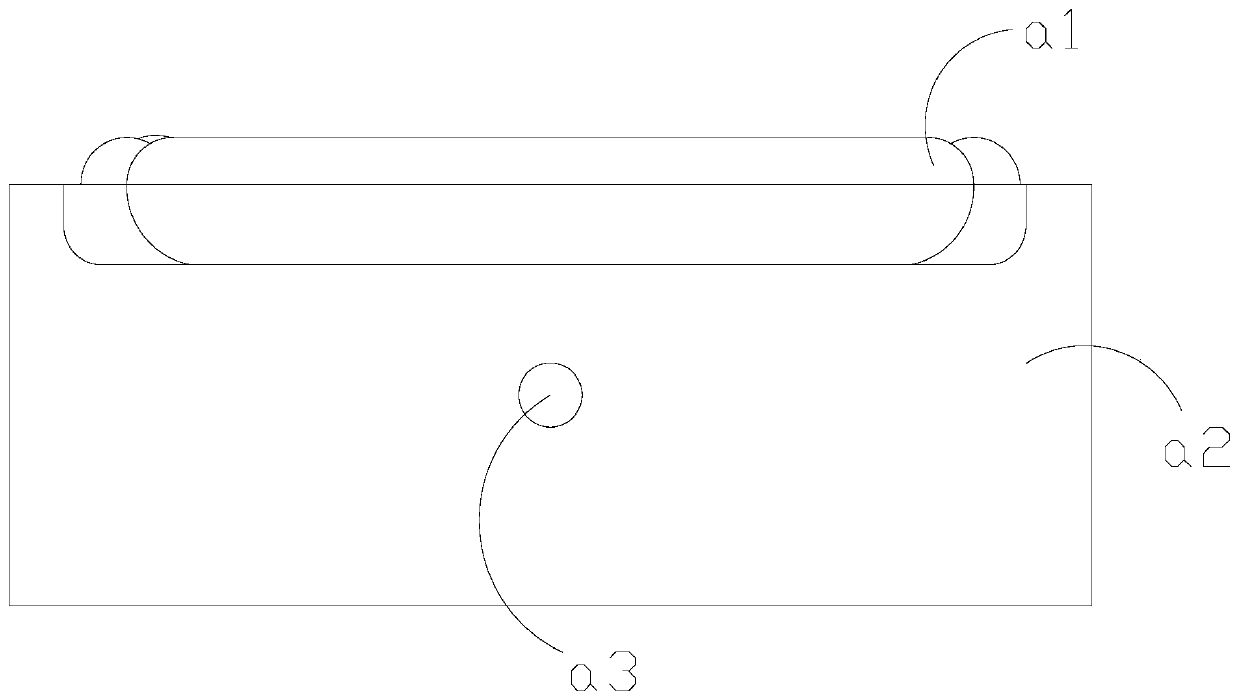

[0031] The block lock control device 4 includes an air-mounted bar a1, a die a2, and a plug a3, the air-placed bar a1 is installed inside the die a2 by embedding, and the die a2 and the plug a3 are integrated structure.

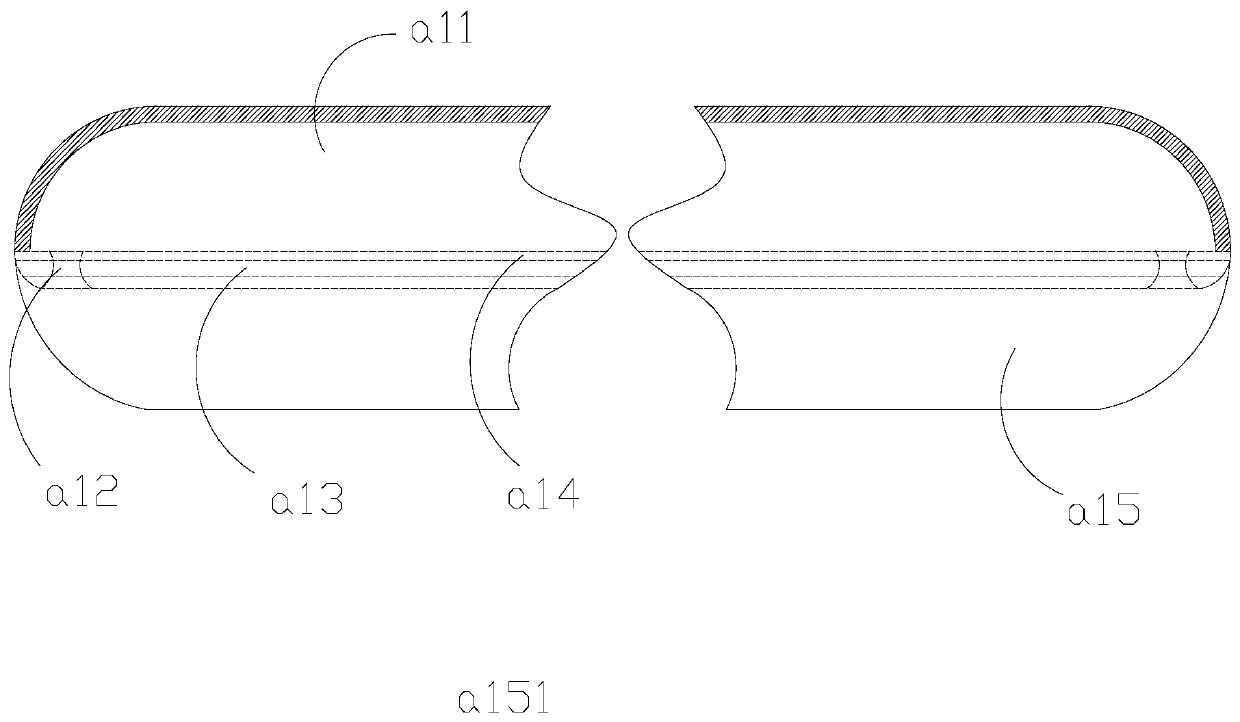

[0032] Wherein, the air placement strip a1 includ...

Embodiment 2

[0039] as attached figure 1 to attach Figure 7 Shown:

[0040] The present invention provides an automatic occlusion forging molding die. The air resistance piece q41 includes a side sliding piece q411, a bottom joint bar q412, and a resistance piece q413. There are two side slide pieces q411 fixedly installed on the resistance piece q413 On the left and right sides, the bottom connecting strip q412 is installed inside the lower part of the blocking plate q413 by embedding, and the side sliding plate q411 is directly in contact with the side chute surface, and the friction coefficient can be greatly reduced through its smooth surface.

[0041] Wherein, the arc buckle q42 is arc-shaped, and the left and right sides are smooth, and are made of high manganese steel with higher hardness.

[0042] Wherein, the envelope q2 is provided with an arc-shaped groove inside, and the right side is in a penetrating state, and the left side is in a closed state.

[0043] The specific usa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com