Mold-clamping sequence control mechanism

A sequence control and template technology, applied in the field of mold clamping sequence control mechanism, can solve the problems of easily damaged structure and complexity of the mold clamping sequence control mechanism, and achieve the effect of simple structure, easy realization and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

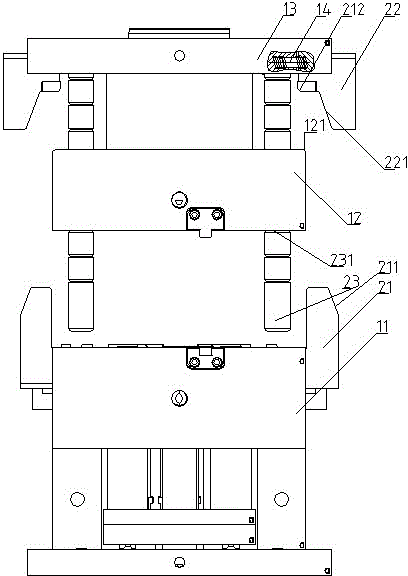

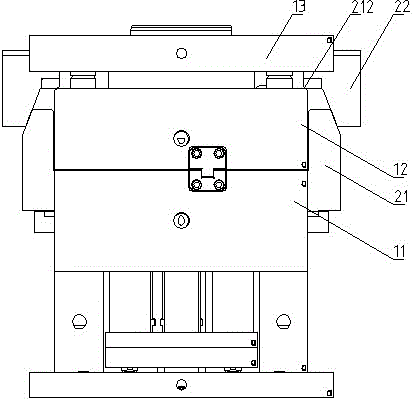

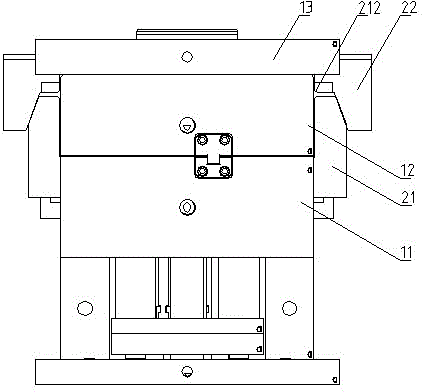

[0034] like Figure 1-3 Shown is a mold clamping sequence control mechanism described in this embodiment, which includes a shifting block 21 and a movable block 22, wherein the shifting block 21 is columnar and long, fixedly arranged on the movable template 11, and the shifting block 21 One end of block 21 long side direction has drive surface 211; Described movable block 22 is arranged on fixed template 13 and is suitable for resetting and moving toward fixed template 13 direction, and described movable block 22 is provided with described drive surface 211 opposite and The sliding fit guide surface 221 and the interference portion 212 adapted to interfere with the middle template 12; the shift block 21 is suitable for pushing the movable block 22 along the guide surface 221 to move away from the fixed template 13; The middle template 12 is in a state of conflict with the conflicting part 212, the middle template 12 pushes the movable block 22 to move away from the fixed templ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com