A lamp holder automatic assembly machine

An assembly machine and assembly mechanism technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as labor-intensive, failure to meet assembly standards, and looseness of two parts, and achieve high efficiency, convenient movement and precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

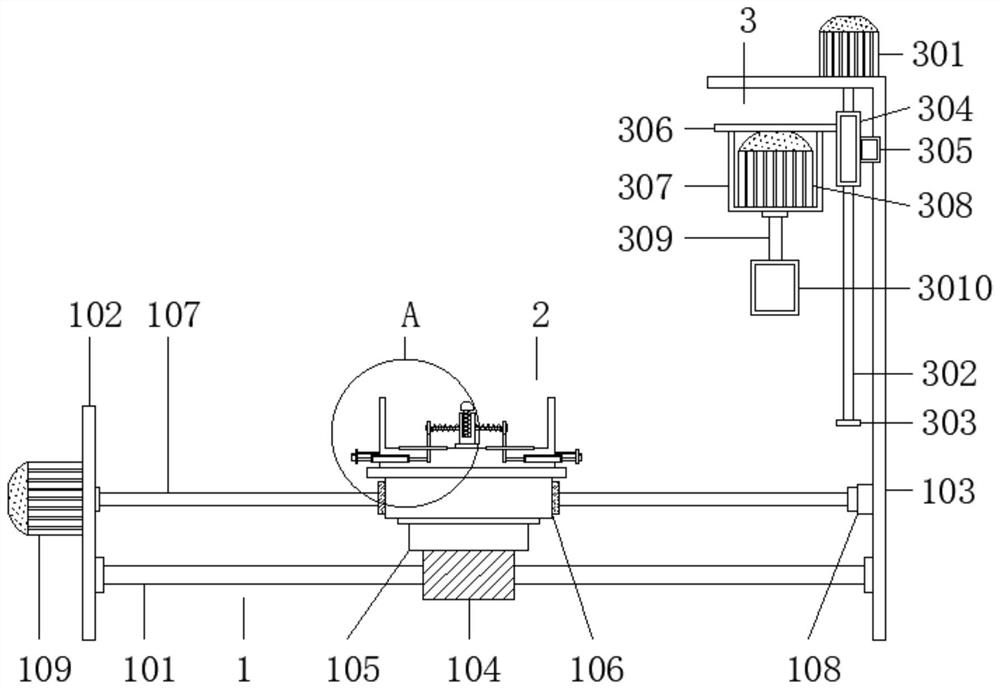

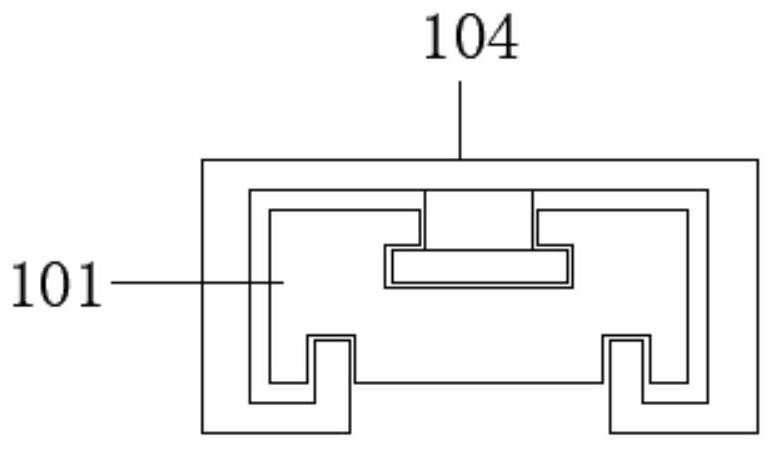

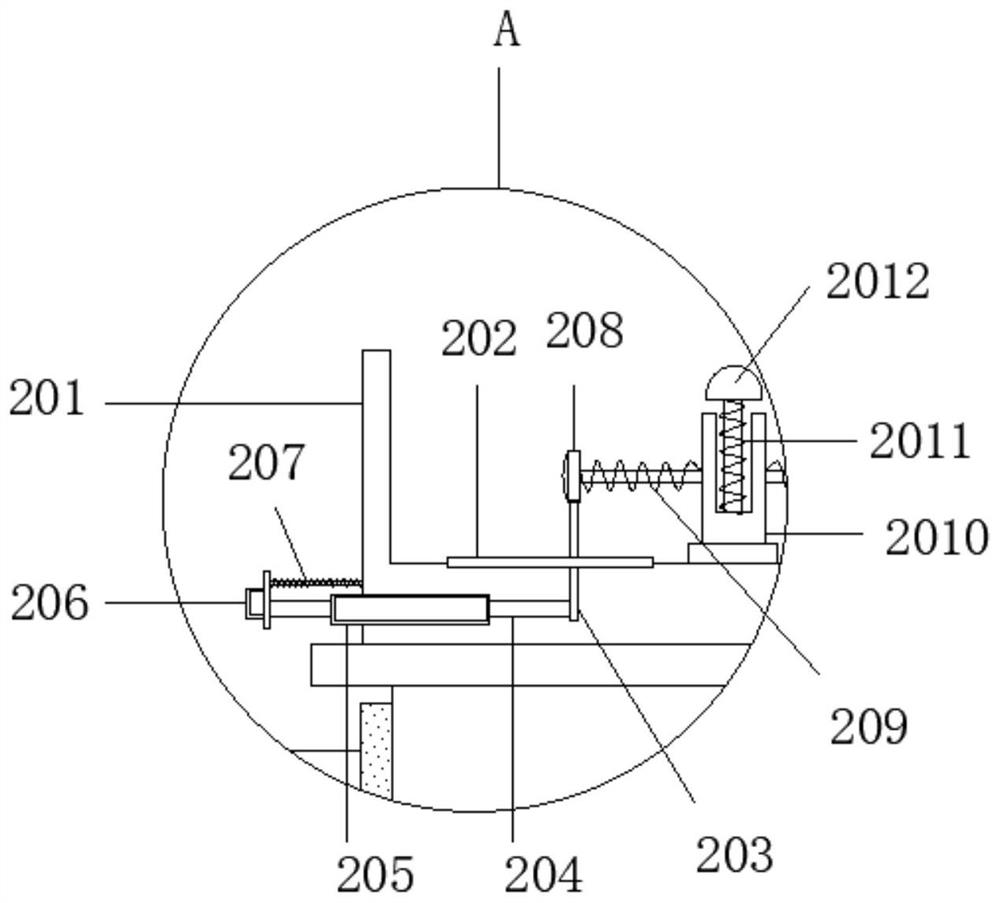

[0020] Such as Figure 1-3 As shown, this specific embodiment adopts the following technical solutions: an automatic lamp holder assembly machine, including a moving mechanism 1, a clamping mechanism 2 is arranged on the moving mechanism 1, and the moving mechanism 1 on one side of the clamping mechanism 2 An assembly mechanism 3 is arranged on it, and the moving mechanism 1 includes a slide rail 101, a left support plate 102 is fixedly connected to one side of the slide rail 101, and a left support plate 102 is fixedly connected to the other side of the slide rail 101 relative to the left support plate 102. There is a support frame 103, a slide block 104 is slidably connected to the slide rail 101, a No. 1 connecting plate 105 is fixedly connected above the slide block 104, and the No. 1 connecting plate 105 is slidably connected to the slide rail 101 through the slide block 104, A No. 1 movable threaded sleeve 106 is fixedly connected to the other side of the No. 1 connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com