Visual heat transfer experiment platform for microporous bubbling technology

An experimental platform and micro-hole technology, which is applied in the field of visual heat transfer experimental platform, can solve the problem of not being able to visualize the influence of bubble movement on the temperature field, and achieve the effect of visual experiment and accurate collection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

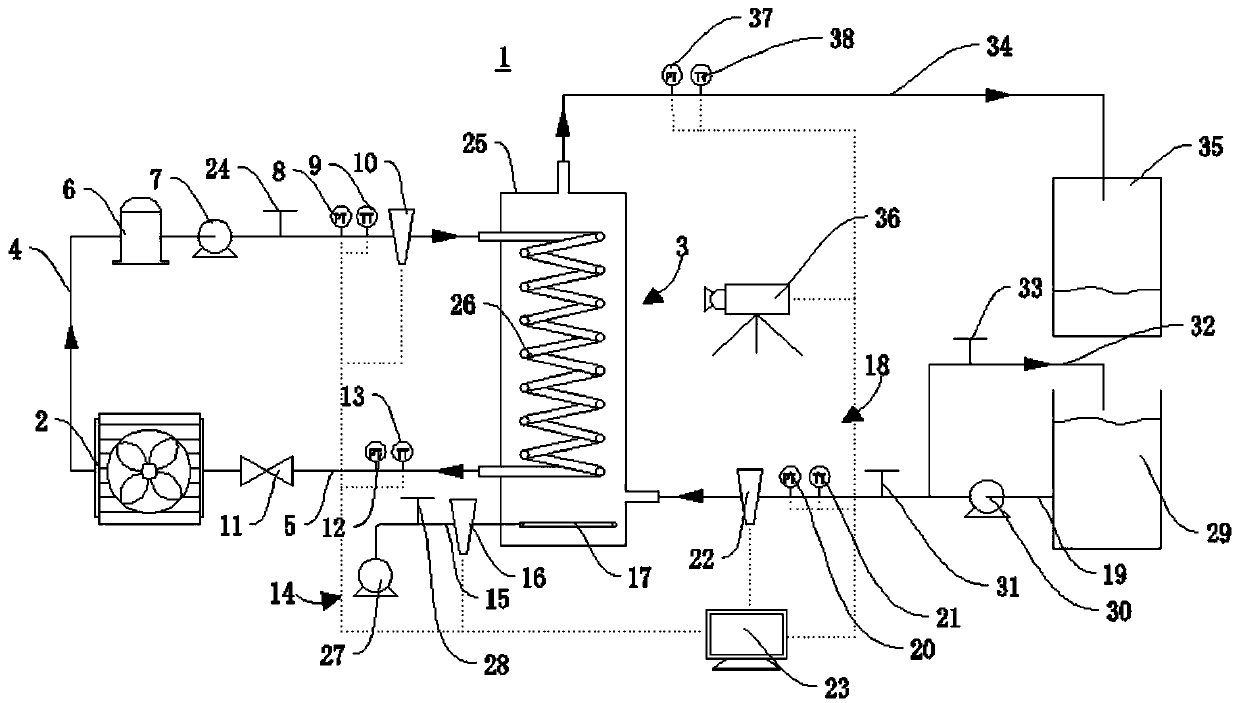

[0035] Please refer to figure 1, the present application provides a visual heat transfer experiment platform 1 for microporous bubbling technology, including an evaporator 2, a heat exchanger 3, an air supply assembly 14, a water supply assembly 18, a data collector 23 and a processor, wherein, The heat exchanger 3 between the evaporators 2 is connected through the refrigerant inlet pipe 4 and the refrigerant outlet pipe 5 respectively, and a compressor 6, a circulation pump 7, a first pressure sensor 8, and a first temperature sensor 9 are sequentially installed on the refrigerant inlet pipe 4 And the first flow sensor 10, the expansion valve 11, the second pressure sensor 12 and the second temperature sensor 13 are installed in sequence on the refrigerant outlet pipe 5; the air supply assembly 14 is connected to the heat exchanger 3 through the air delivery pipe 15, and A second flow sensor 16 is installed on the gas pipe 15 . And, the microporous bubbler 17 that is used fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com