Fibre strand integrated composite device for ring spindle spinning

A ring spinning and fiber technology, which is applied to spinning machines, textiles and papermaking, and continuous winding spinning machines. It can solve the problems of high hairiness and low strength in yarns, and achieve improved hairiness, low cost, and The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

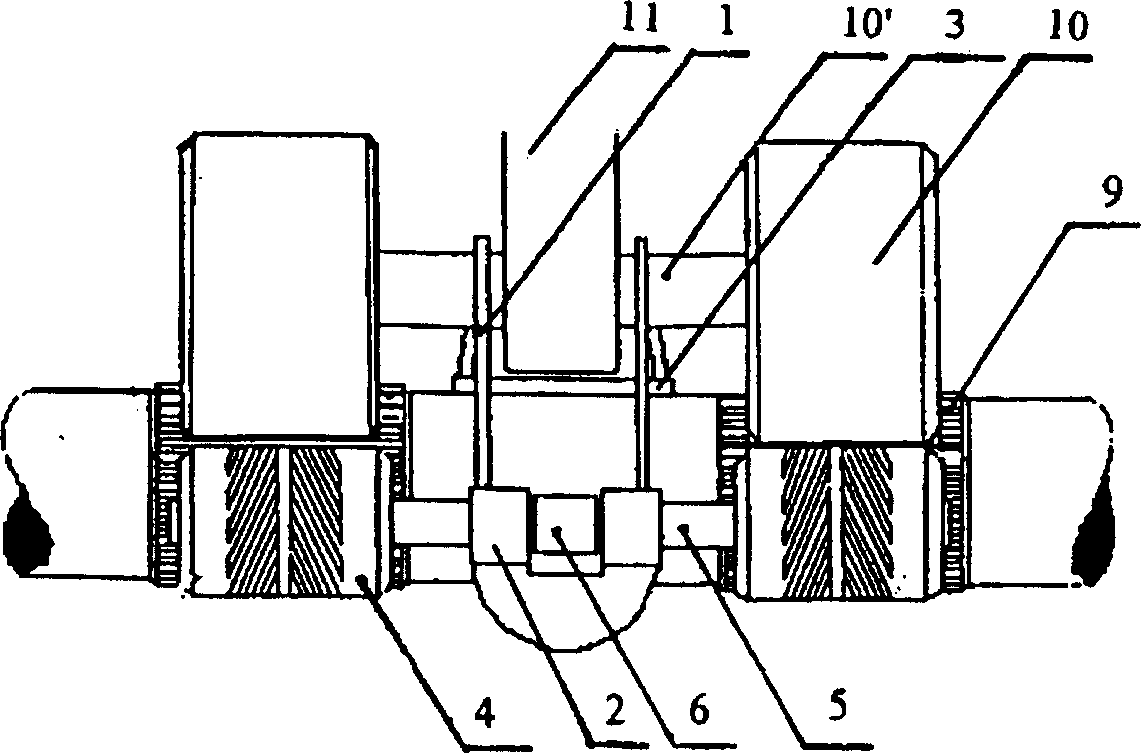

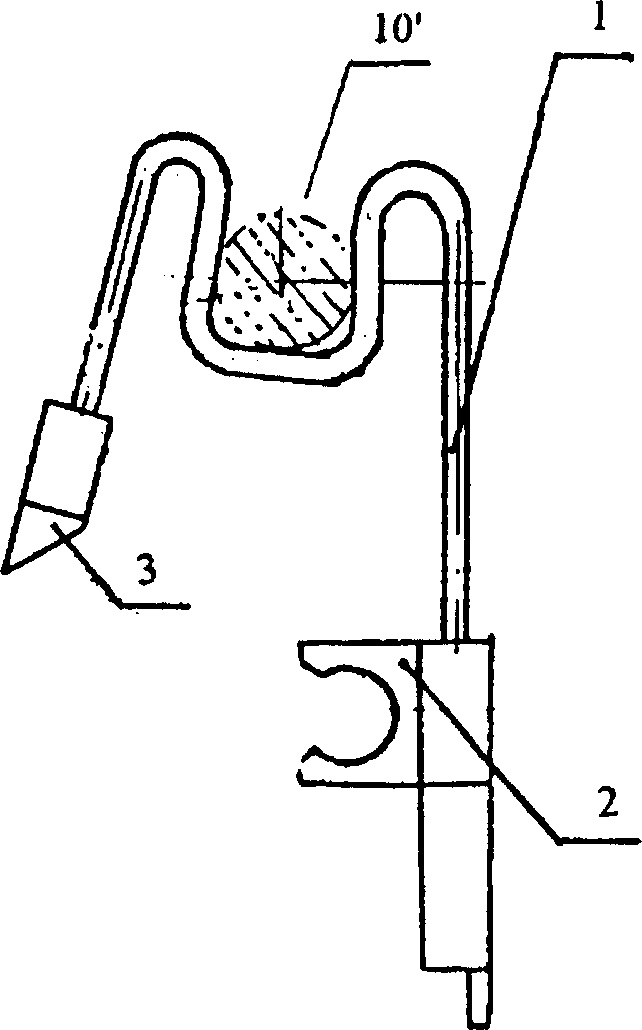

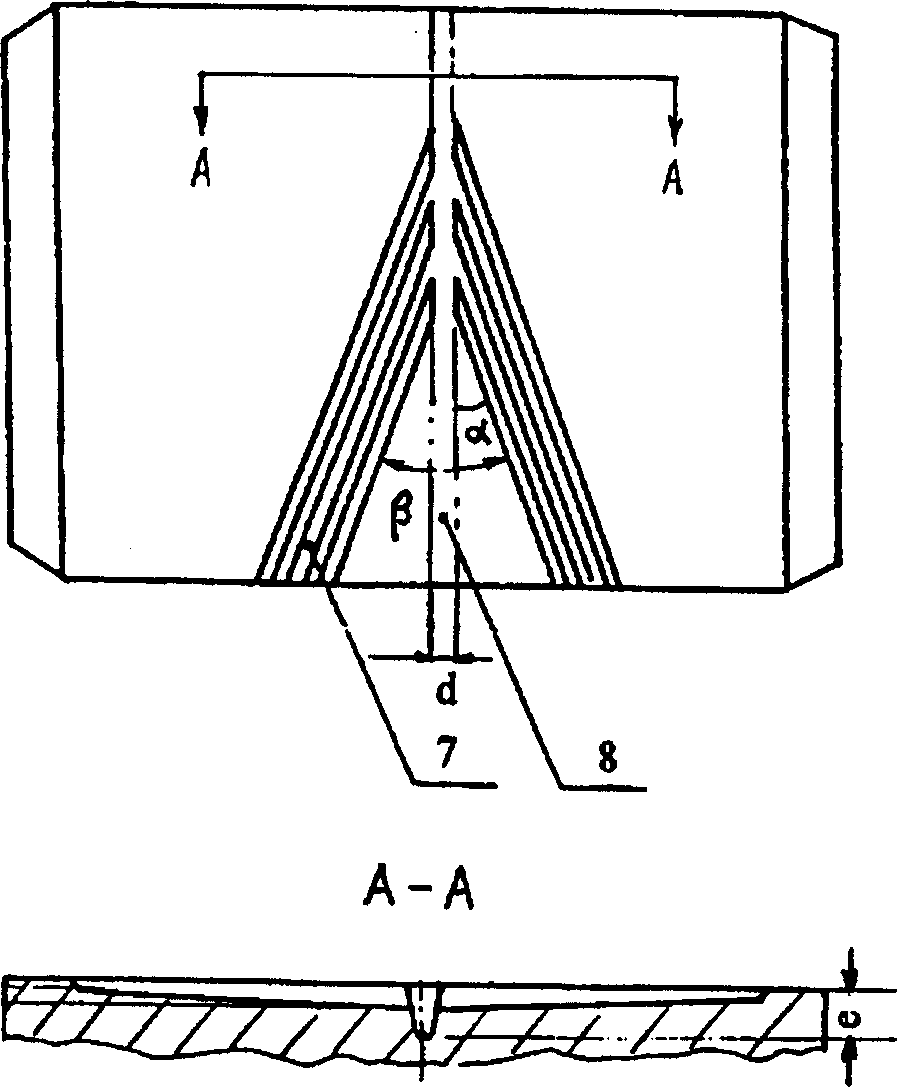

[0020] Such as figure 1 , image 3 As shown, the ring spinning fiber strand gathering device is installed at the exit of the front roller 9 nip in the front drafting area, and the diameter of a pair of gathering roller 4 of the gathering roller is smaller than that of the front roller 9, which is convenient for the front roller 9 to move At the same time, the front top roller 10 and the accumulation roller 4 are accommodated. The function of the accumulation roller is not to pull or draft the fiber strands, but the fiber strands pass through the split guide groove on the pair of accumulation rollers 4 of the accumulation rollers before entering the twisting zone. The groove 7 splits the fiber strands, and guides the split fiber strands to the accumulation groove 8 on the accumulation roller 4, and when twisting, the twisted strands will be twisted deep into the accumulation groove 8 for accumulation. The untwisted fiber strands in the groove 8 are effectively twisted, thereby...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com