Automatic transfer switching equipment

A technology of automatic transfer switch and micro switch, which is applied in the direction of electric switches, circuits, electrical components, etc., can solve the problems of inability to accurately reflect the working status of automatic transfer switch electrical appliances, potential safety hazards, and inaccurate feedback of contacts, and achieve simple structure , high reliability and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

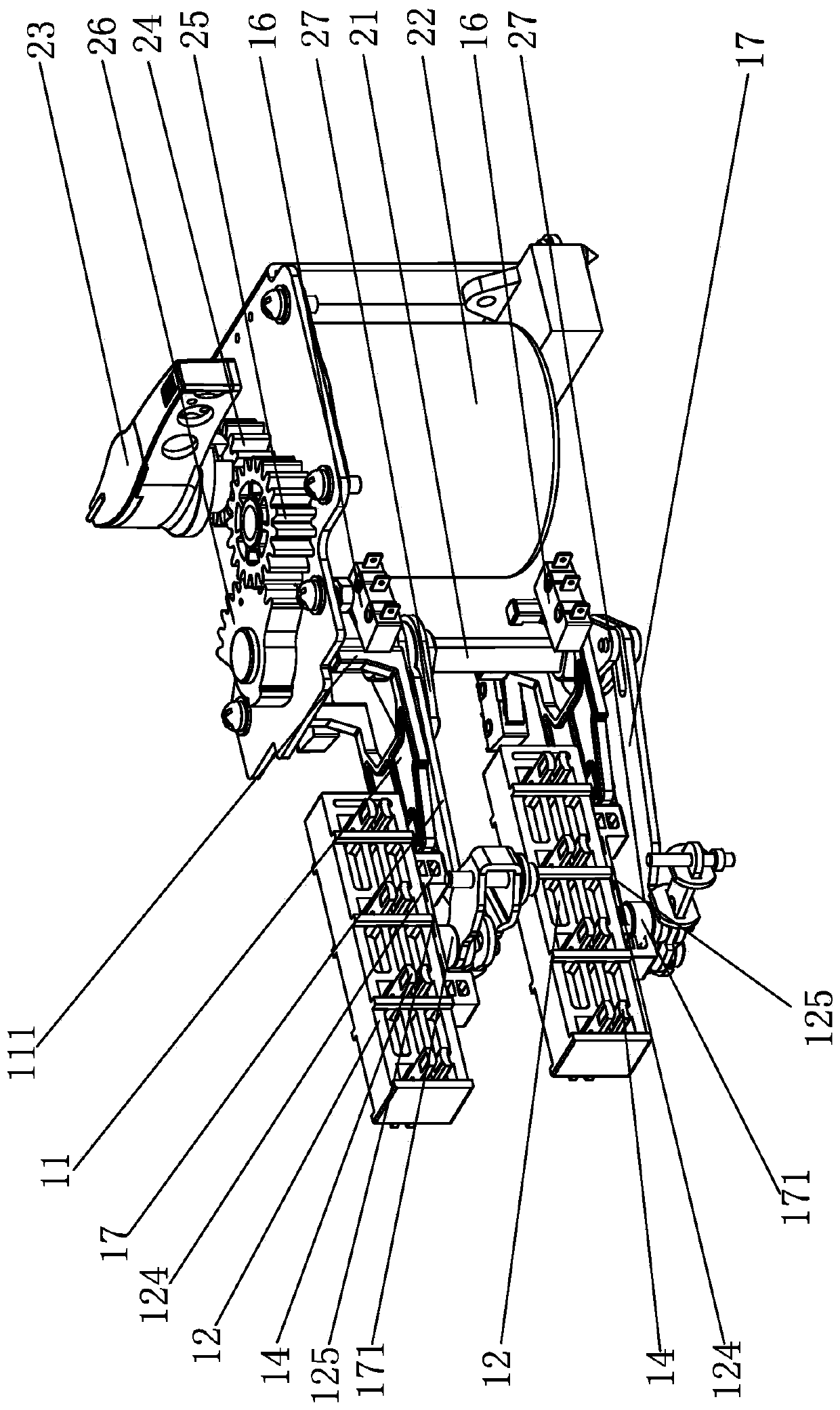

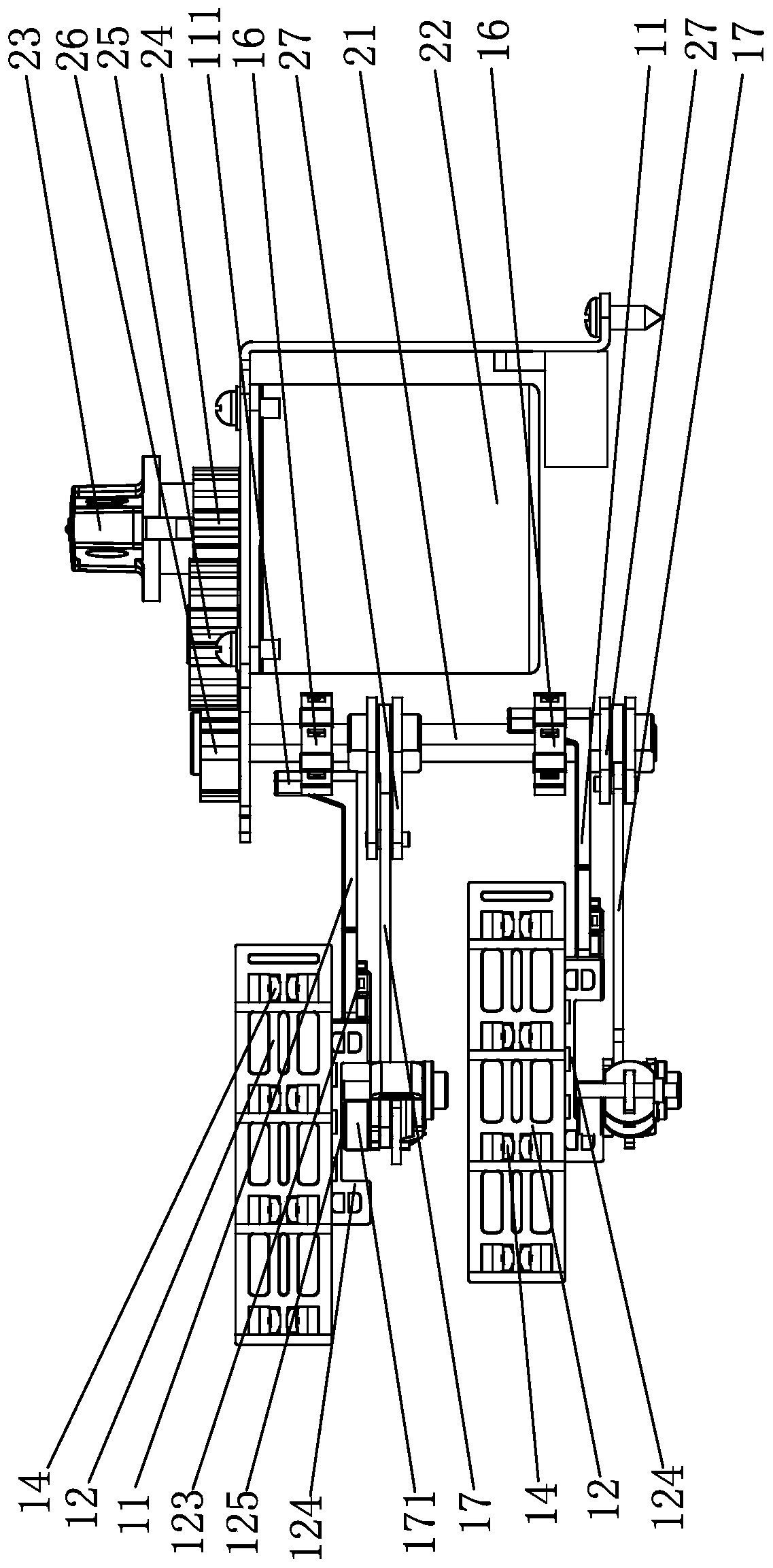

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

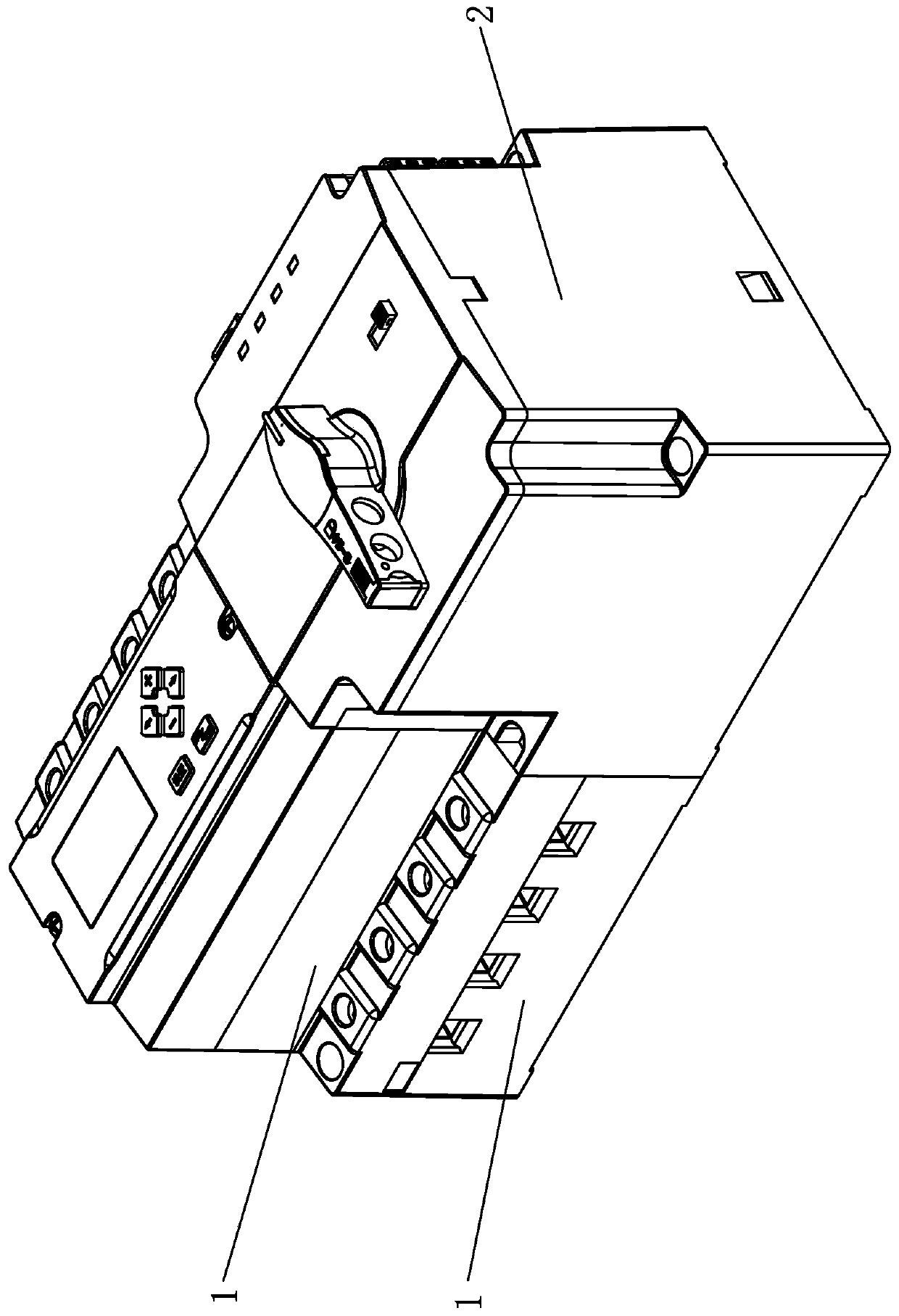

[0026] Such as Figure 1-Figure 5 As shown, the specific embodiment of the present invention is an automatic transfer switch electrical appliance including an operating mechanism 2 and two groups of contact systems 1, the operating mechanism 2 includes a casing and a drive shaft 21, a motor 22, a handle 23, and a drive shaft arranged in the casing. Gear 24, transmission gear 25, driving gear 26, driving gear 24 and handle 23 are connected on the output shaft of motor 22, driving gear 24 is arranged between motor 22 and handle 23, driving gear 26 center is connected with drive shaft 21, transmission The gear 25 is connected between the driving gear 24 and the driving gear 26. The driving shaft 21 is a semi-shaft structure. The driving shaft 21 is provided with two sets of protruding driving pieces 27. The orientations of the two groups of driving pieces 27 are inconsist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com