Biological liquid fuel and preparation system and method thereof

A technology for the preparation of biological liquids and fuels, which is applied in the direction of liquid carbon-containing fuels, waste fuels, fuels, etc., and can solve the problems of general stirring effect, single stirring method of stirring tank, and low flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

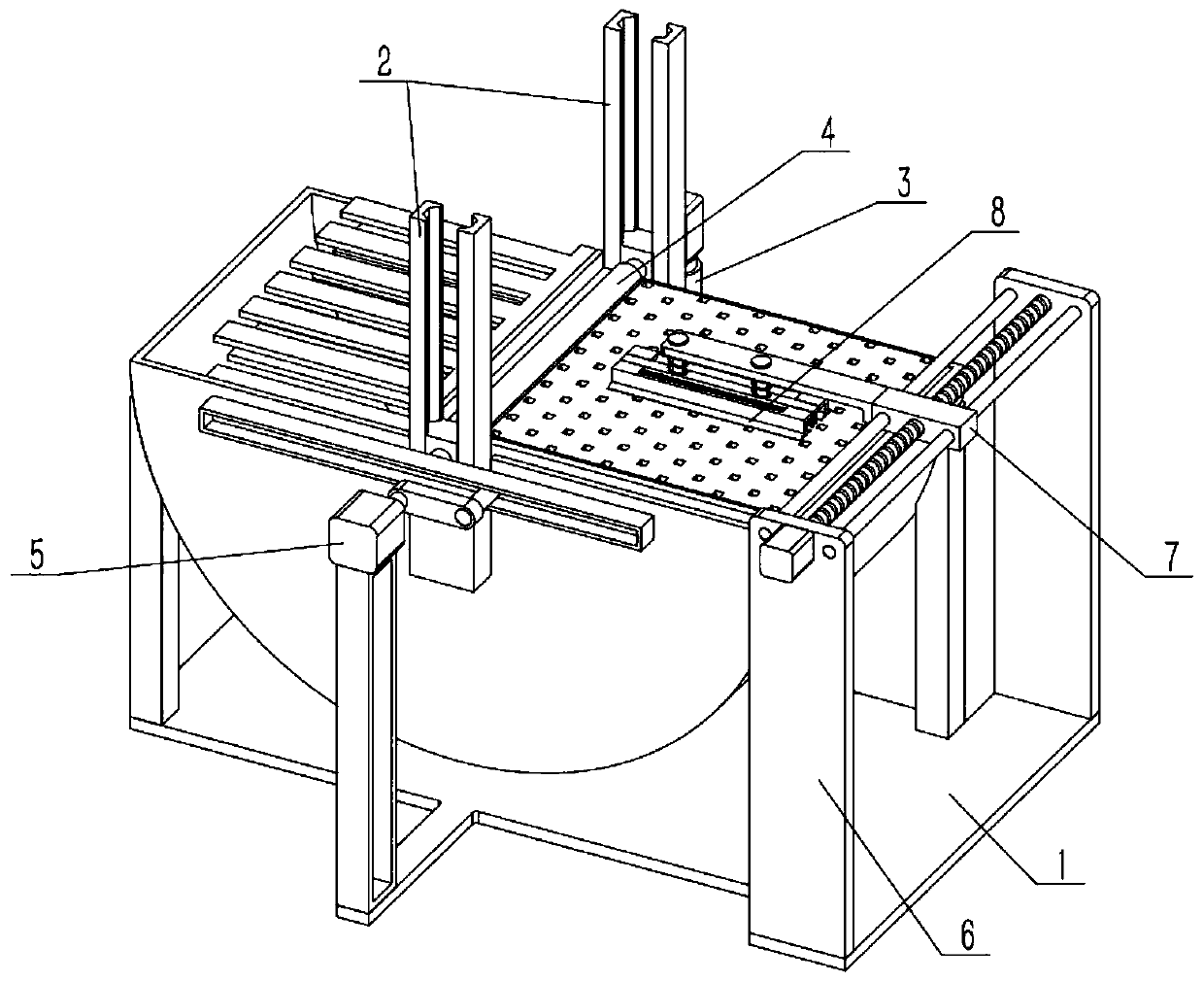

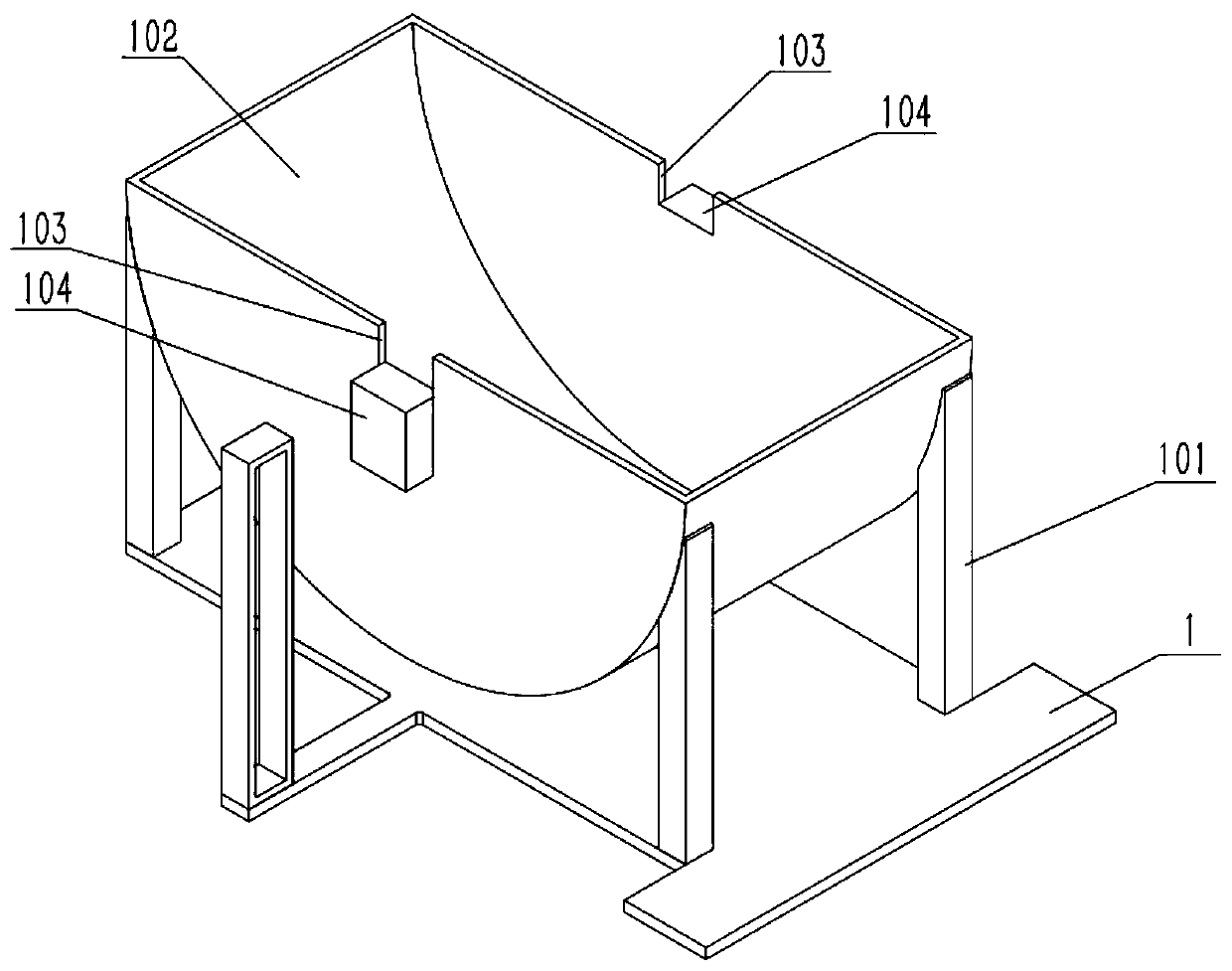

[0034] Such as Figure 1-9 As shown, a biological liquid fuel preparation system includes a base 1, a column 101, a preparation box 102, a casing 4, a filter screen 401 and a first stirring piece 402, the base 1 is fixed to the column 101, and the preparation box 102 is fixed Connected to the upper end of the column 101, one end of the casing 4 is provided with an integrally formed frame-like structure, and the filter screen 401 is affixed in the frame-like structure, and fixed at a position mirrored symmetrically with the filter screen 401 on the sleeve pipe 4 Connected to the first stirring piece 402 , the filter screen 401 performs the filter residue and stirring operation when the filter screen 401 performs circular motion in the preparation box 102 , and the first stirring piece 402 performs the stirring operation when the reciprocating swing movement is made in the preparation box 102 . When the sleeve pipe 4 starts to make a circular motion, the sleeve pipe 4 drives the...

specific Embodiment approach 2

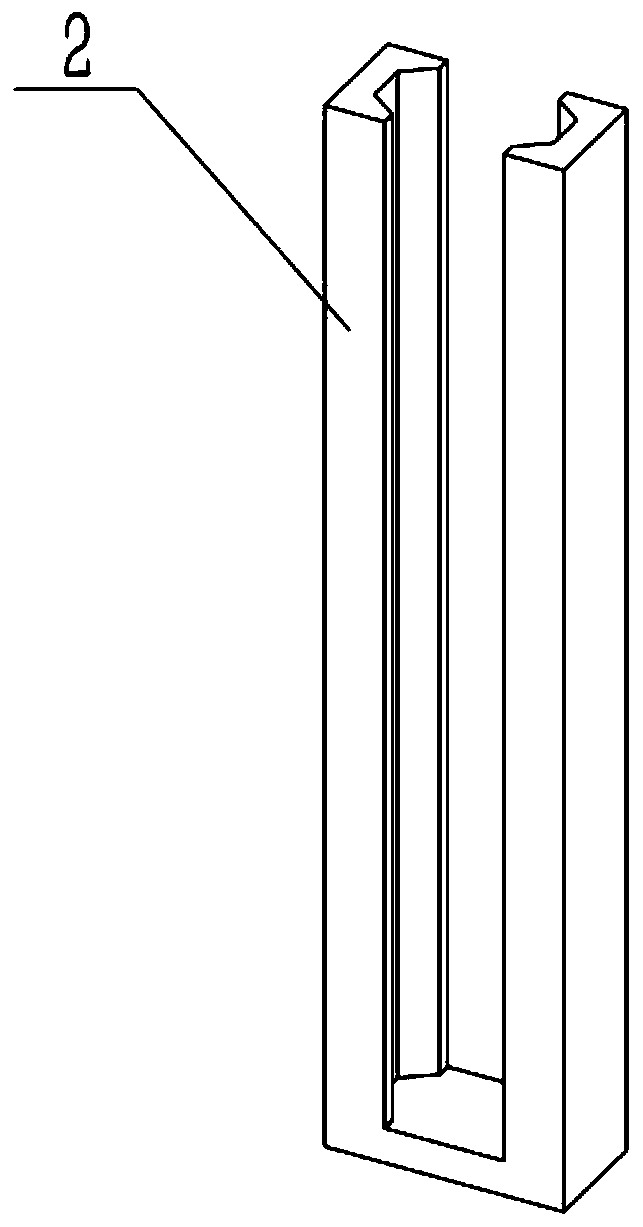

[0036] Such as Figure 1-9As shown, the biological liquid fuel preparation system also includes a base 104, a guide seat 2, an electric push rod 3, a first shaft seat 301, a main shaft 302, a second shaft seat 303, a transmission frame 304, a motor I5, a connecting rod 501 and Connect the shaft 502, the front and rear ends of the preparation box 102 are fixedly connected with a guide seat 2, the electric push rod 3 is fixed on the base 1, and the movable end of the electric push rod 3 is fixedly connected with the first shaft seat 301, the first The shaft seat 301 is rotatably connected to one end of the main shaft 302, the other end of the main shaft 302 is fixedly connected to the transmission frame 304, and the two sides of the main shaft 302 are respectively rotatably connected to a second shaft seat 303, and the two shaft seats 303 are respectively slidably connected to two guide seats. 2, the casing 4 is fixedly connected to the main shaft 302, the motor I5 is fixedly co...

specific Embodiment approach 3

[0038] Such as Figure 1-9 As shown, the biological liquid fuel preparation system also includes a second stirring piece 403, the second stirring piece 403 is fixed on the sleeve 4, the second stirring piece 403 is on the same side as the first stirring piece 402 and the two are respectively Arranged in a row, the second stirring pieces 403 are arranged in parallel with the first stirring pieces 402 and the two are arranged alternately. Alternating double row setup increases stirring effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com