Patents

Literature

30 results about "Bioliquids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bioliquids are liquid fuels made from biomass for energy purposes other than transport (i.e. heating and electricity). Bioliquids are usually made from virgin or used vegetable and seed oils, like palm or soya oil. These oils are burned in a power station to create heat, which can then be used to warm homes or boil water to make steam. This steam can then be used to drive a turbine to generate electricity.

Modified biomass comprising synthetically grown carbon fibers

InactiveUS20100205858A1Low costLow equipment costMaterial nanotechnologyCarbon compoundsFiberCarbon fibers

Biomass particles are modified by associating the particles with carbon fibers. The carbon fibers may be coated onto the biomass particles, or may be embedded within the biomass particles. As a result of the association with carbon fibers the particles are more susceptible to conversion to bioliquid.

Owner:KIOR INC

Biological treatment method and waste-water treatment agent for refractory wastewater

InactiveUS20130299421A1Reduce generationEfficient methodBacteriaWaste water treatment from animal husbandryRefractoryWastewater

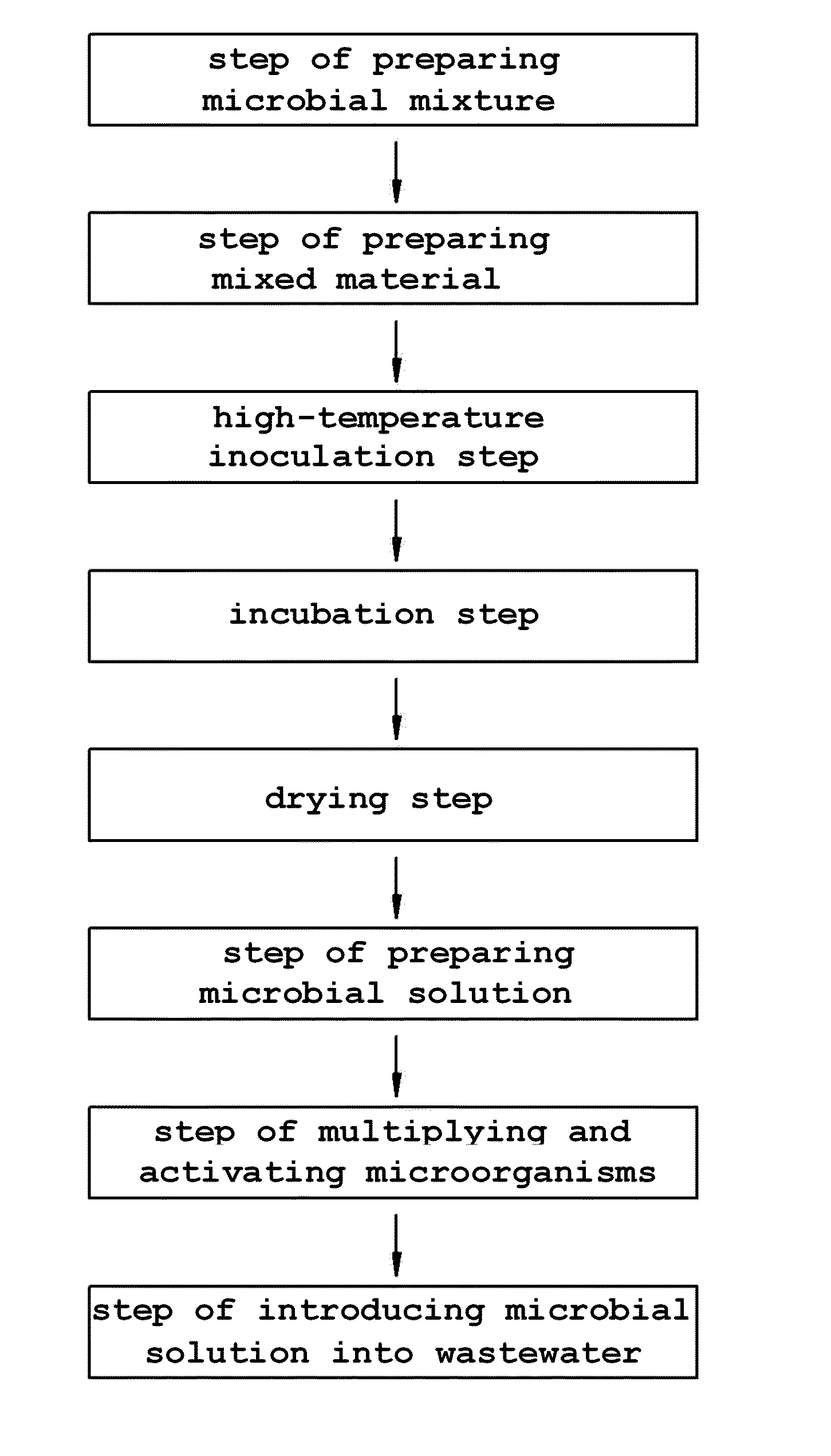

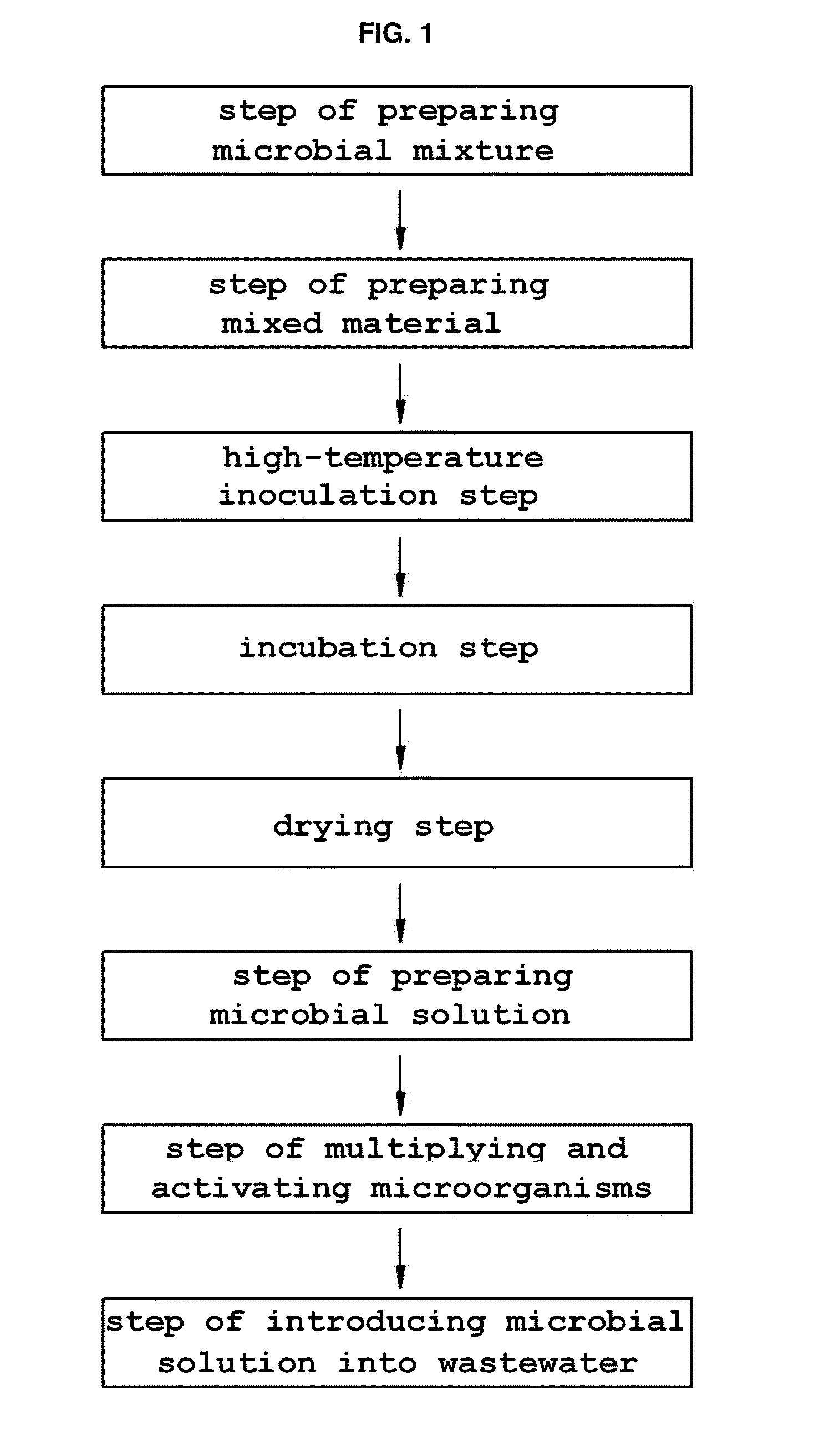

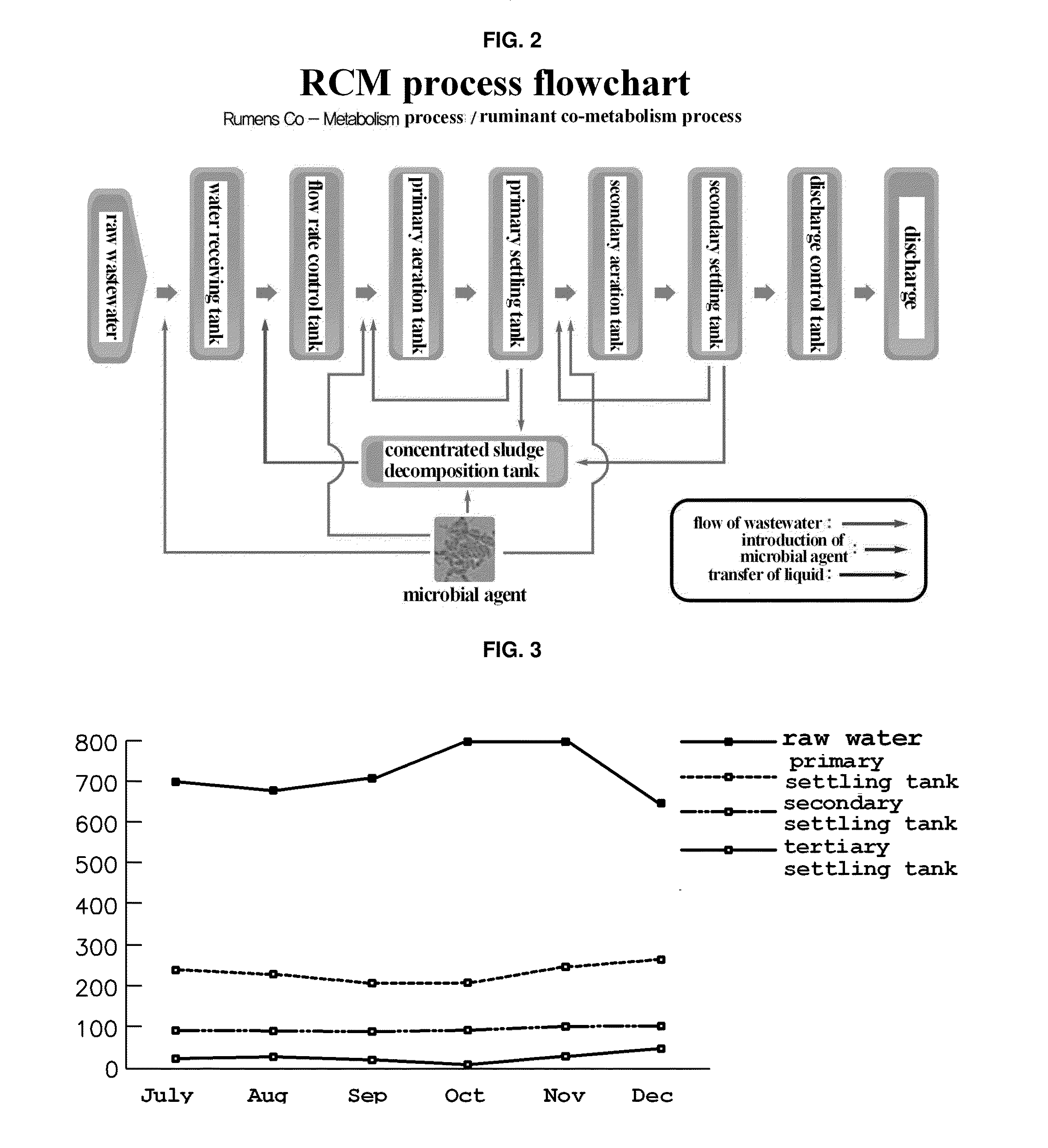

The biological treatment method for refractory wastewater of the present invention includes: a step of producing a complex microbial liquid by maintaining, at between 15 and 28° C., a complex microbial liquid obtained by mixing between 0.01 and 1 percent by weight of mixed microorganisms BM-S-1 (Repository Deposit No. KCTC 11789BP), between 0.1 and 1 percent by weight of powdered chaff, between 0.1 and 1 percent by weight of powdered peat moss, between 1 and 5 percent by weight of molasses, between 0.01 and 1 percent by weight of shiitake mushroom waste wood dust and between 92 and 98 percent by weight of water; a mixed stock production step; a high-temperature inoculation step; a culturing step; a drying step; a microbial starting broth production step; and a microbe activation step.

Owner:KOREA MARITIME UNIV IND ACADEMIC COOPERATION FOUND +1

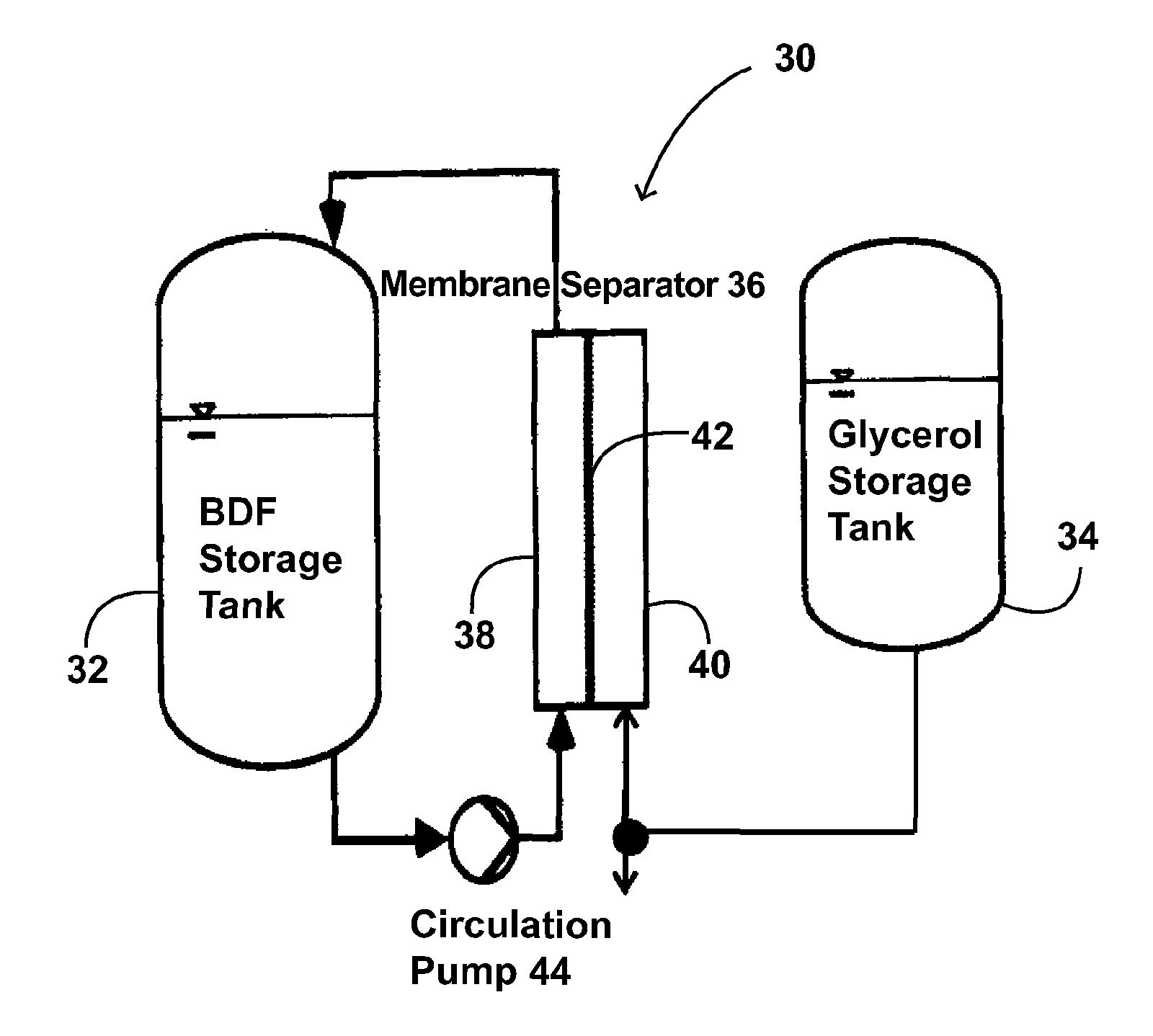

Methods and apparatus for controlling moisture in plant oils and liquid biofuels

InactiveUS20130305592A1Promote hydrolysisGood hygroscopicityFatty oils/acids recovery from wasteDewatering/demulsification with chemical meansBiodieselFuel tank

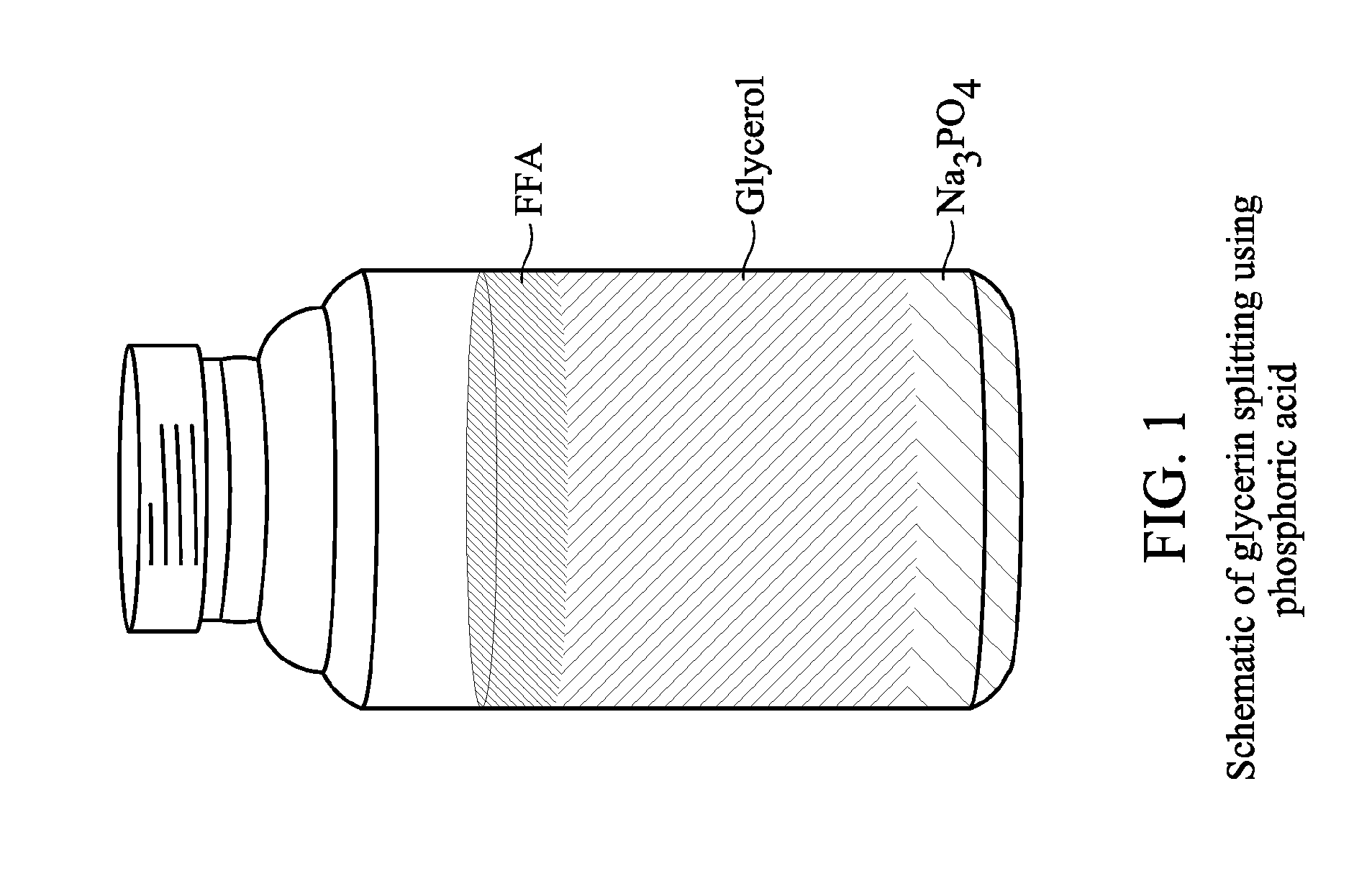

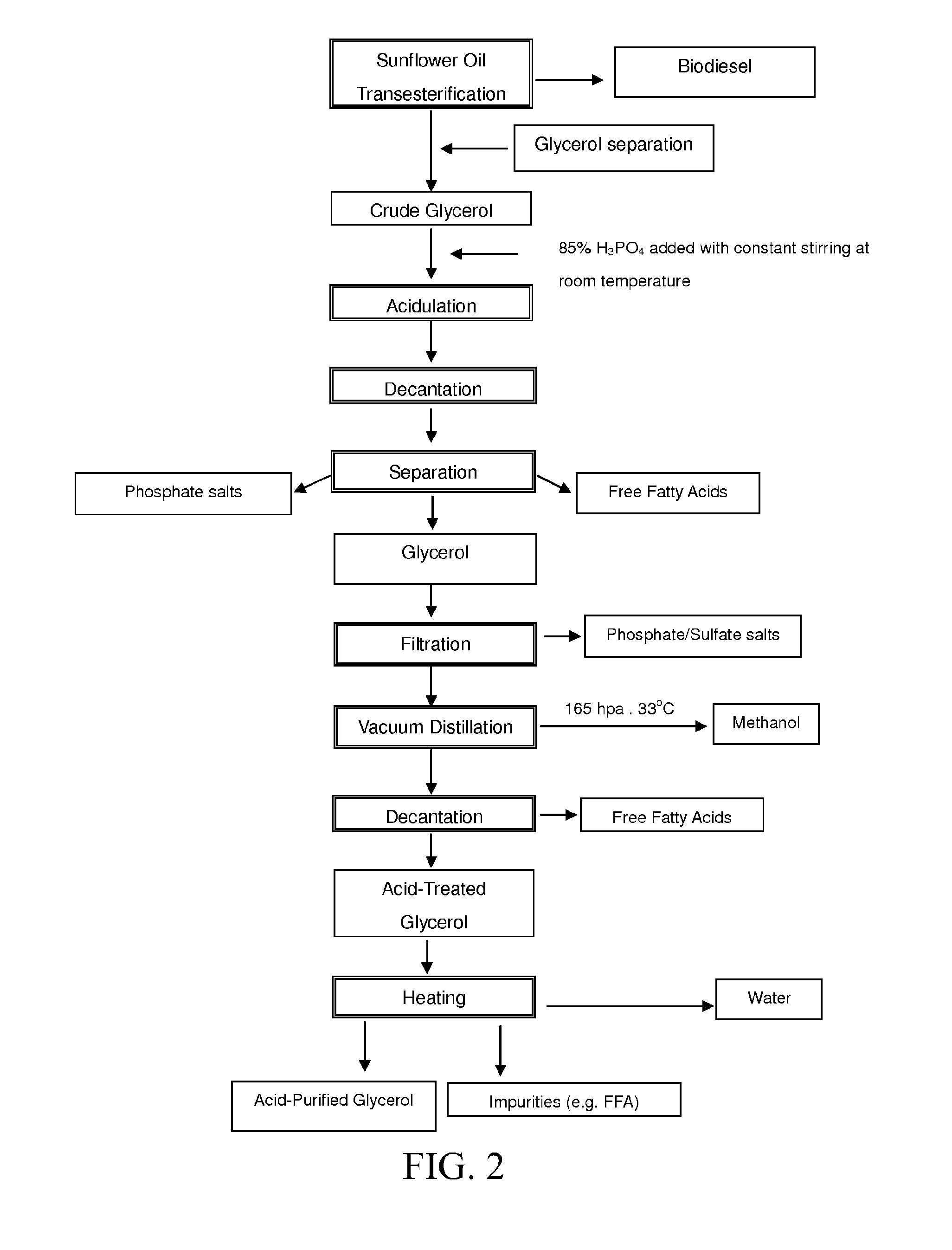

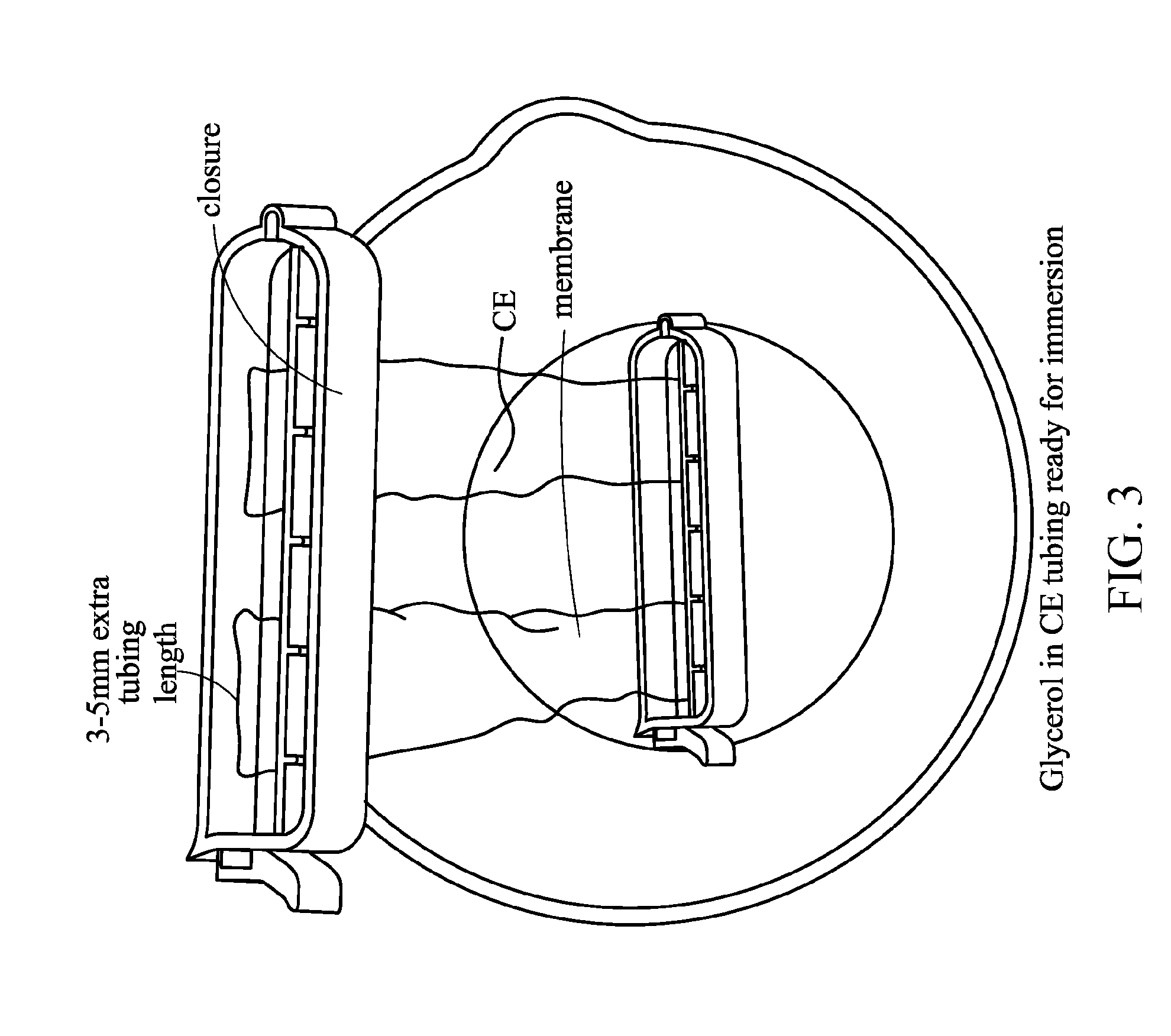

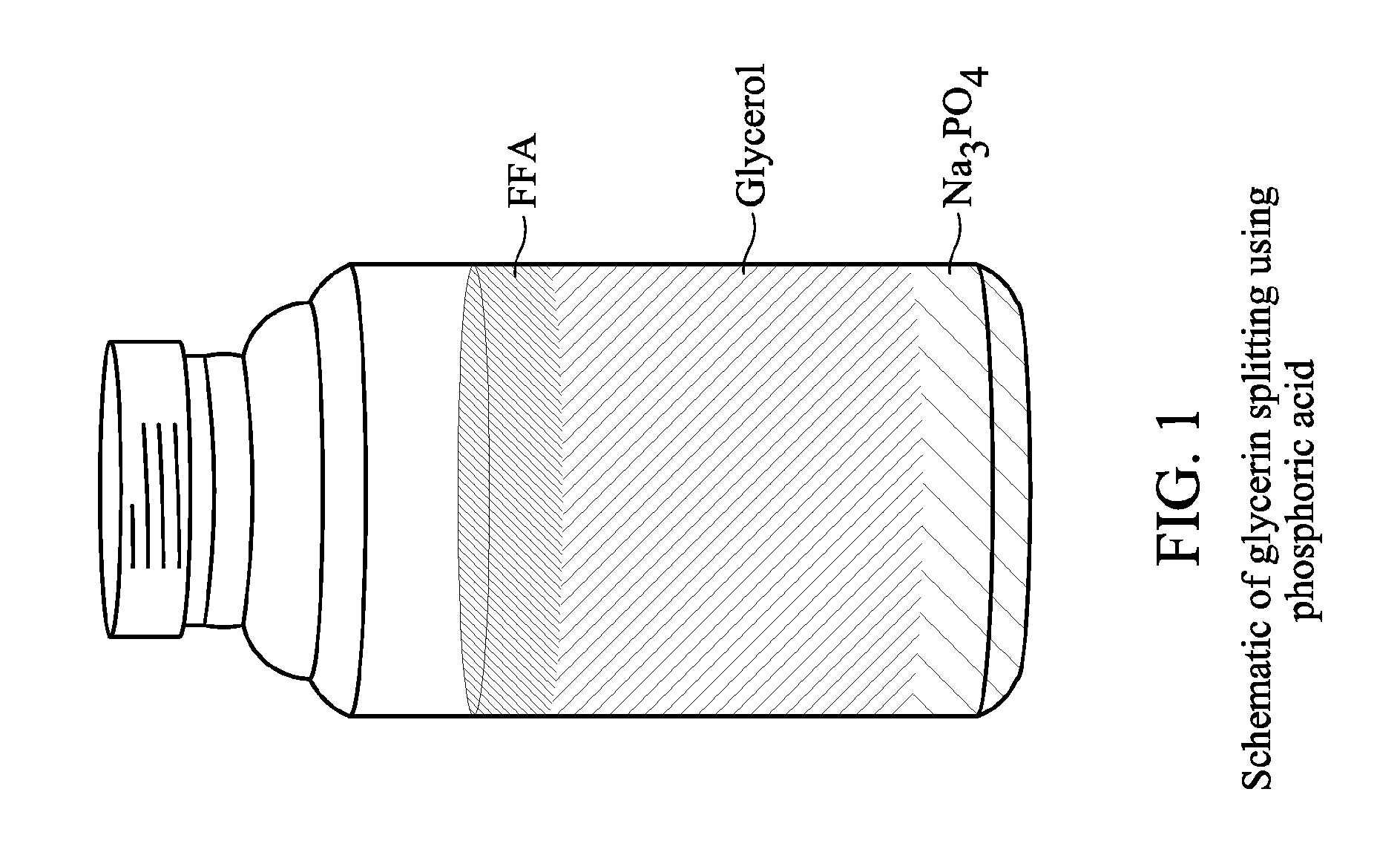

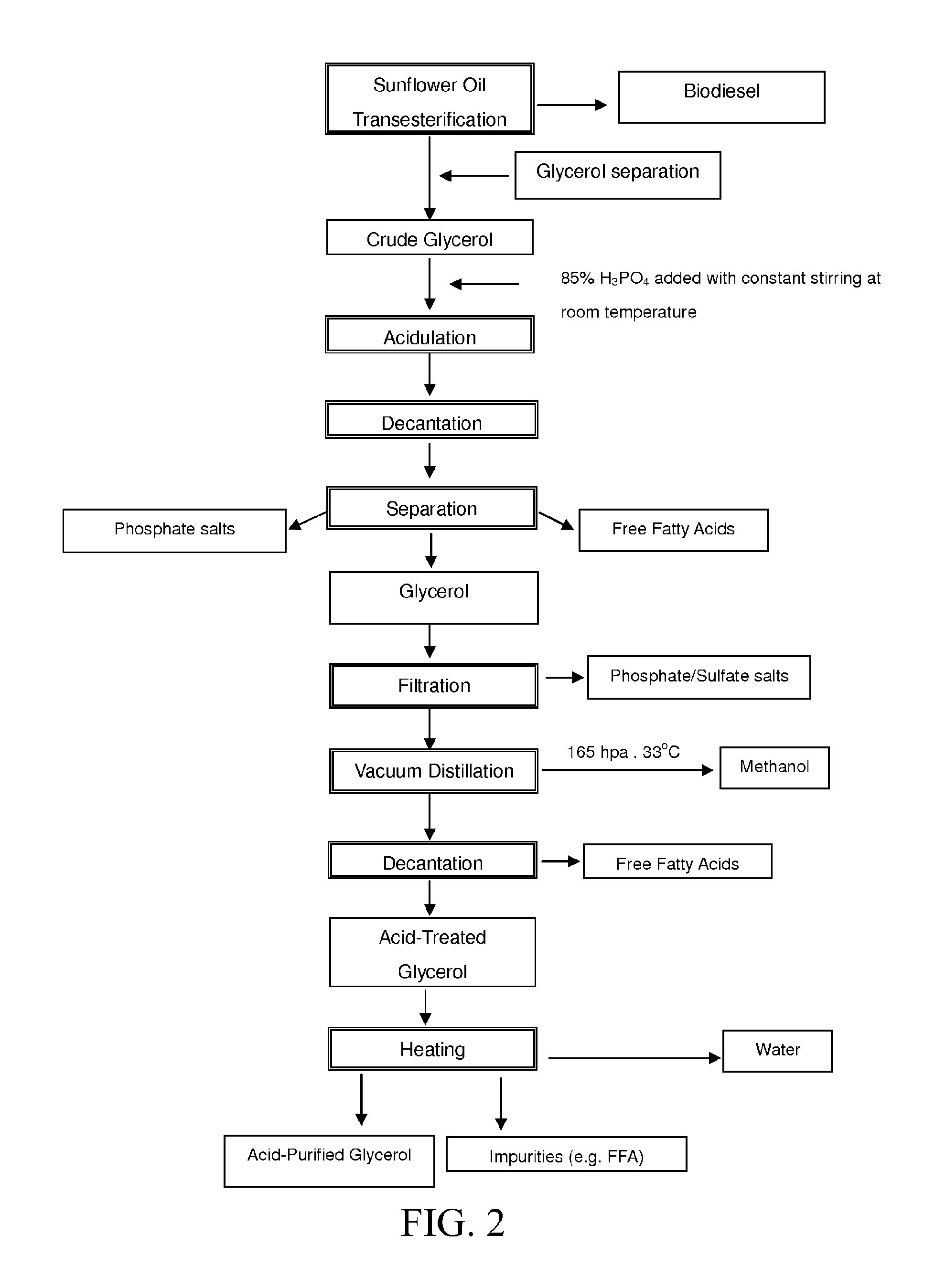

The moisture absorption capacity of biofuels can be more or less 10 times that of fossil diesel oil, causing biofuels to form acids that induce metal corrosion and form deposits in the fuel tank and pipe lines. Methods for removing moisture from stored biofuels and plant oils are described wherein glycerol is used as a solvent to extract the moisture from the bioliquid or oil, comprising the steps of placing the biofuel or oil in fluid contact with glycerol, incubating for a time, and then removing the glycerol. A cellulous ester dialysis or other semi-permeable membrane may be used to prevent the glycerol from contaminating the biofuel while allowing moisture to pass. Crude glycerol produced as a by-product of biodiesel production may be used in the method of the disclosed invention with good result. Preferred embodiments of apparatus that employ the method of the subject invention are described.

Owner:MATSUMURA MASATOSHI

Method for catalyzing liquefaction of plant raw material by supercutical fluid

ActiveCN103555353AIncrease liquefaction rateReduce pollutionLiquid hydrocarbon mixture productionPtru catalystPropanoic acid

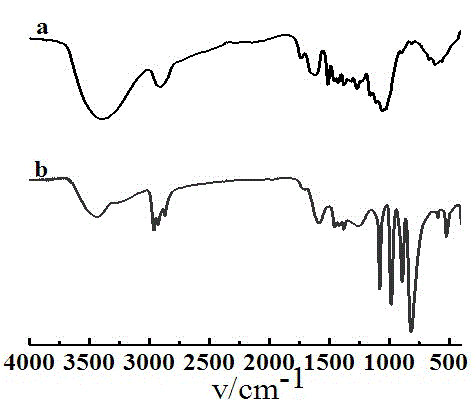

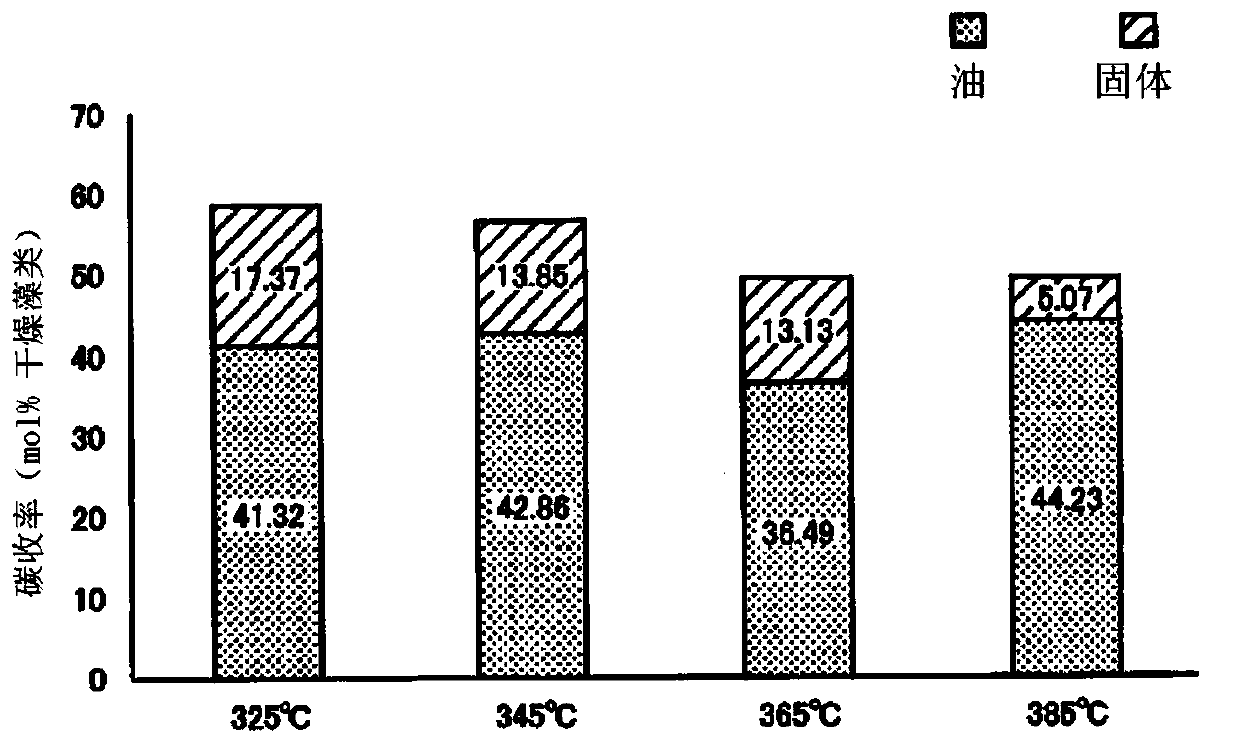

The invention discloses a method for catalyzing the liquefaction of a plant raw material by a supercutical fluid. The method comprises the following steps: 1, crushing the plant raw material, sieving by a 40-60 mesh sieve, and drying; and 2, adding the plant raw material and an alcoholic solvent into an autoclave, reacting in a supercritical state for 10-50min with a solid heteropoly acid as a catalyst, eluting the obtained liquefied product with anhydrous ethanol, carrying out pumping filtration, and carrying out rotary evaporation to obtain biomass oil. The method substantially improves the liquefaction rate of the plant raw material; the method adopting the solid heteropoly acid as a catalyst to substitute a traditional liquid strong acid catalyst, such as H2SO4, HCl and HNO3, has the advantages of small environmental pollution, no corrosion to an apparatus, easy separation and the like; and the obtained biomass oil has a high content of esters, has a highest levulinate content reaching 20.82%, can be directly used as a gasoline additive and biological liquid fuel oil, has the advantages of non-toxicity, high lubricity, high gross calorific value and the like, and is clean energy.

Owner:FUJIAN AGRI & FORESTRY UNIV

Microbial liquid manure and preparation method thereof

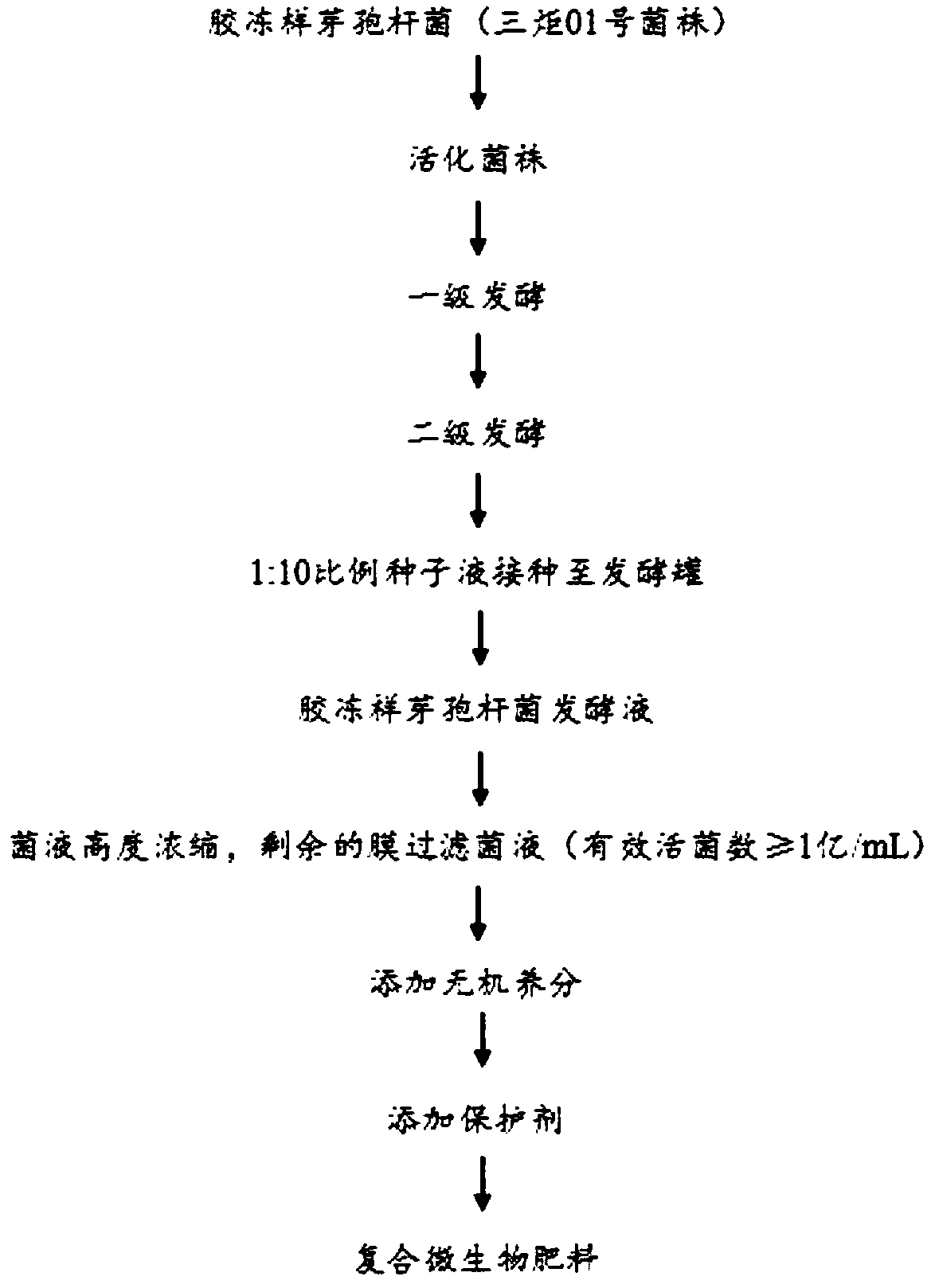

InactiveCN109879695AImprove compactionIncrease the granular structureFertilizer mixturesPotassiumBacterial strain

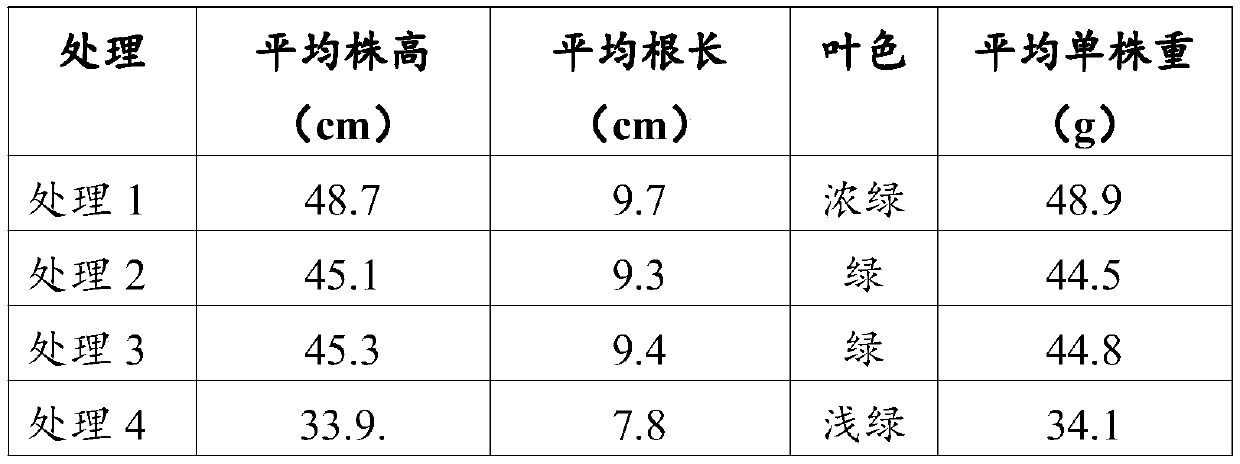

The invention provides liquid manure containing microorganisms and a preparation method of the liquid manure, and relates to the technical field of bacterial manure preparation. The liquid manure usesbacterial liquid prepared from bacillus mucilaginosus as a solvent, and is further prepared from nitrogen, phosphorus and potassium, the nitrogen, the phosphorus, and the phosphorus are counted as N,P2O5 and K2O correspondingly, and the total concentration of the N, the P2O5 and the K2O is not less than 150g / L; and the living bacterium quantity of three No. 01 bacterial strains in the bacterialliquid is no less than 10*108 / mL. The preparation method is simple, the cost is saved, soil hardening can further be improved, the soil aggregate structure is increased, soil water retention propertyis improved, a rhizosphere microbial system is improved, absorption of nutrients by crops is improved, the growth of the crops is facilitated, and thus the quality and yield of the crops are improved.

Owner:漳州三炬生物技术有限公司

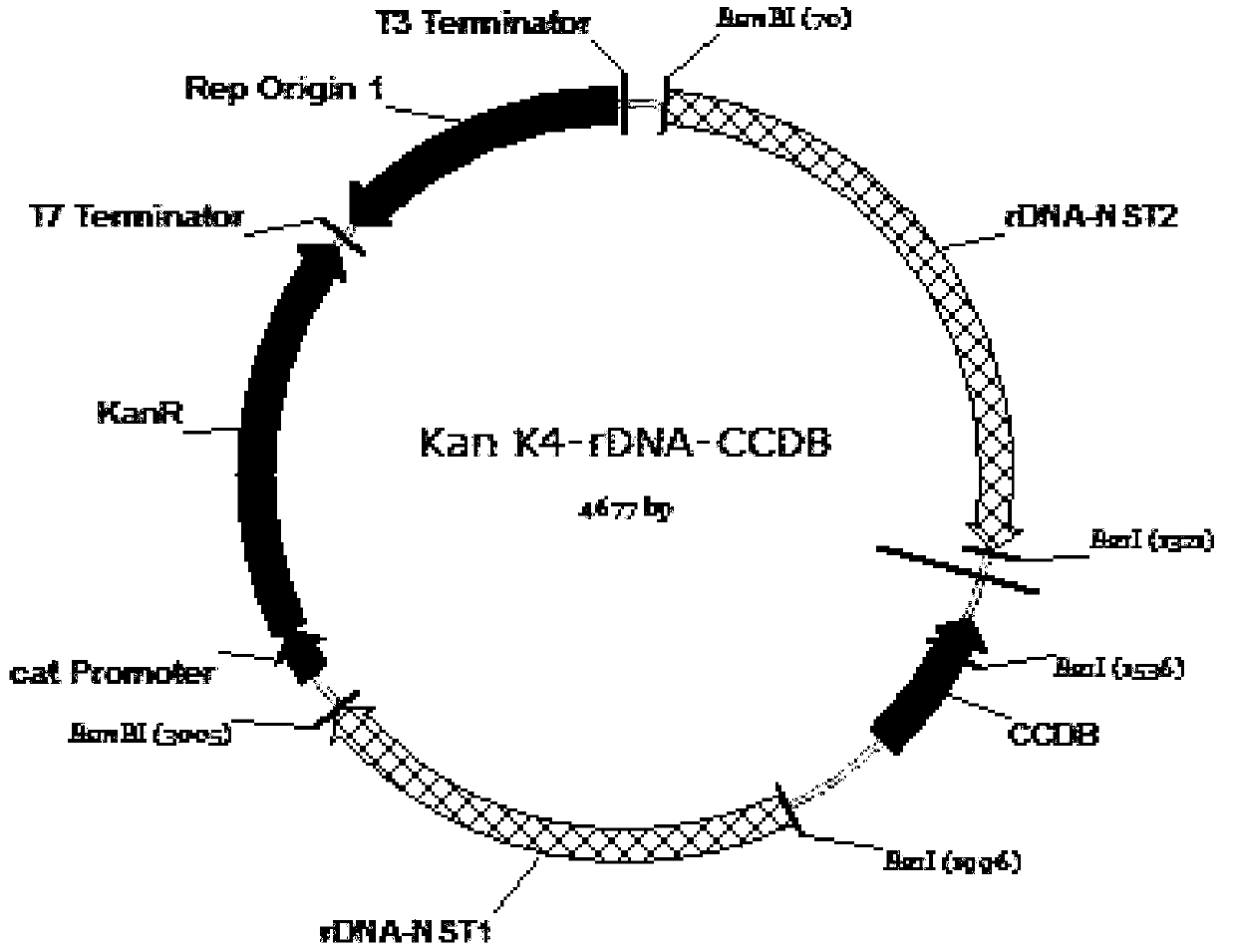

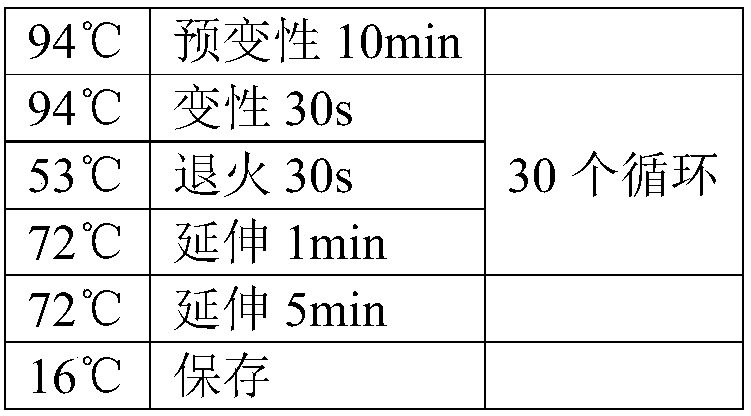

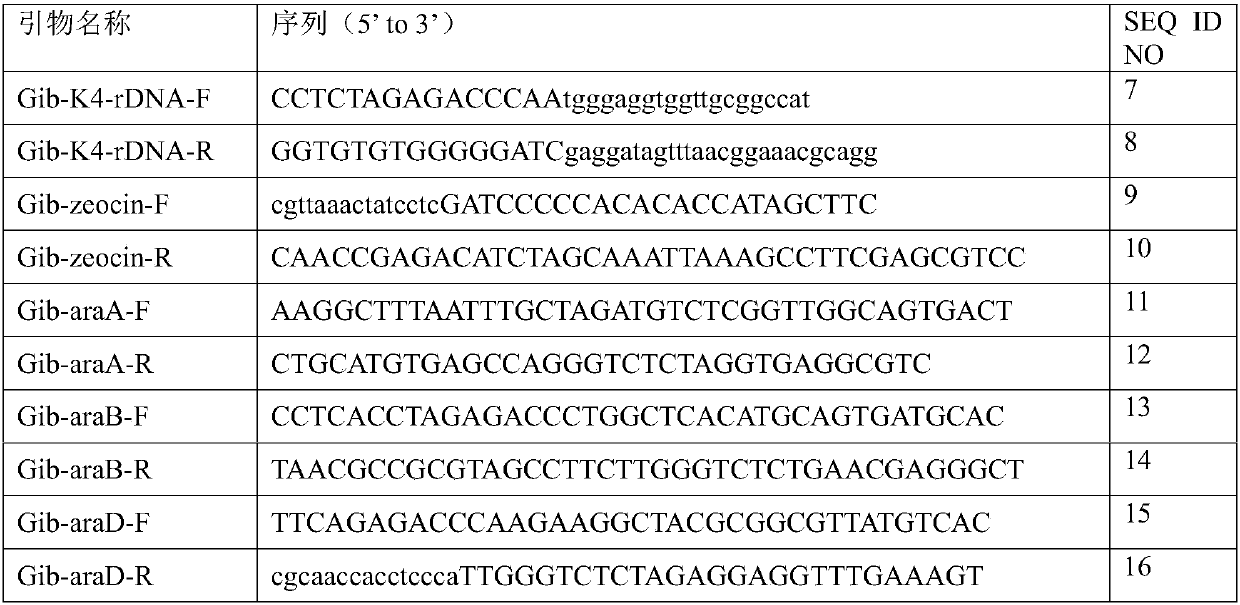

Reorganized saccharomyces cerevisia bacterial strain and preparation method and application thereof

ActiveCN109609540AExcellent fermentation performanceMetabolically efficientFungiBiofuelsBiotechnologyAlcohol sugars

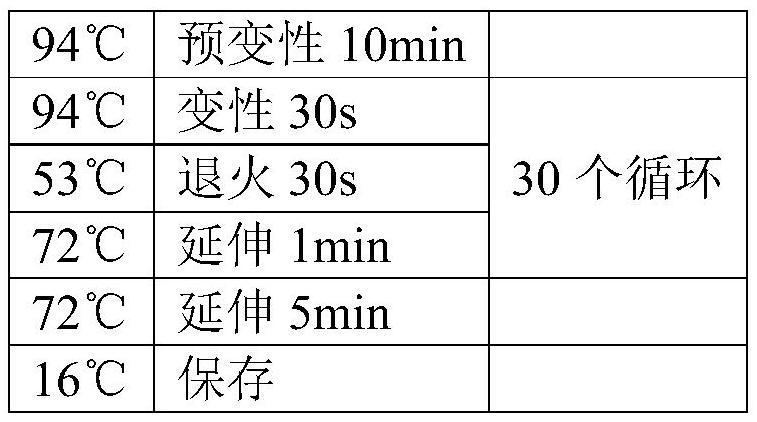

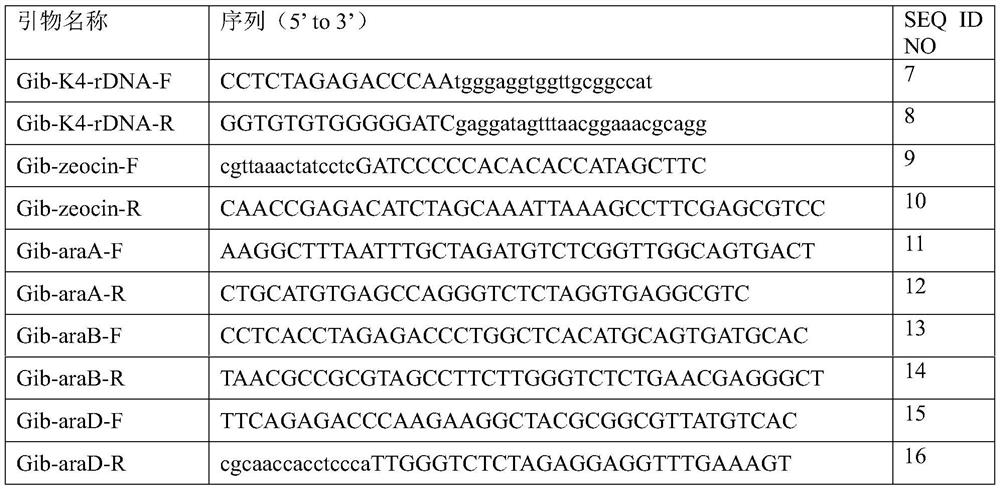

The invention relates to the fields of genetic engineering and metabolism engineering, discloses the fields of genetic engineering and metabolism engineering, and particularly relates to a reorganizedsaccharomyces cerevisia bacterial strain and a preparation method and application thereof. The reorganized saccharomyces cerevisia bacterial strain can express gene expression boxes of genes (1) to (3): (1) araA genes from pediococcus acidilactici; (2) araB genes from lactobacillus plantarum; and (3) araD genes from plant bacterium lacticum. The reorganized saccharomyces cerevisia bacterial strain has arabinose integrated exogenously as a metabolism way of a carbon source, in a technology for preparing biofluid fuel ethanol through fermentation of lignocellulose raw materials, glucose can beused, and arabinose can also be used, conversion rate of 93.2% of sugar alcohol in the lignocellulose raw materials can be realized, the bacterial strain is favorable in fermentability, the yield of ethanol in each ton of the raw materials is increased, the raw material utilization factor is increased, and the reorganized saccharomyces cerevisia bacterial strain is suitable for mass production ofcellulosic ethanol.

Owner:JILIN COFCO BIOCHEM +2

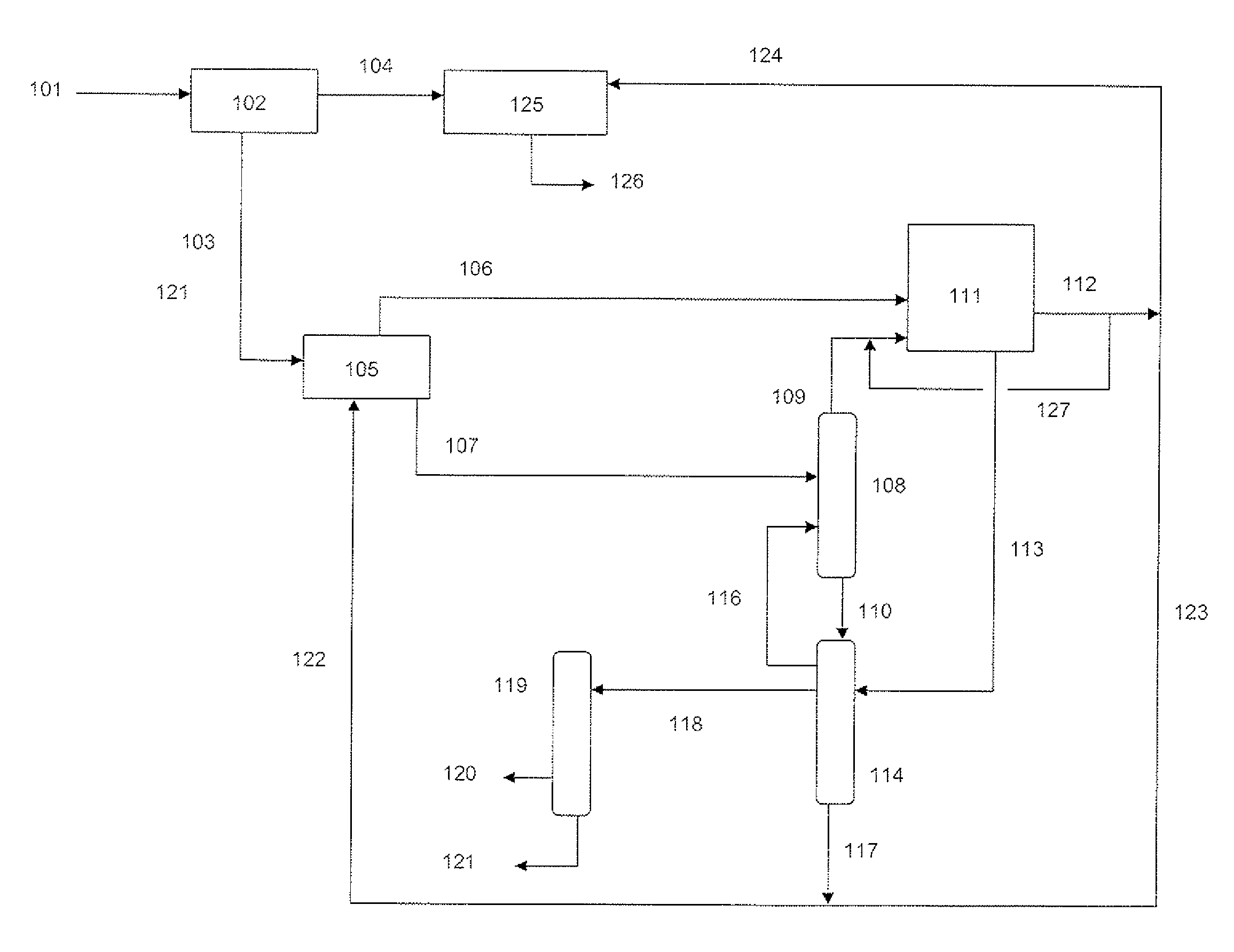

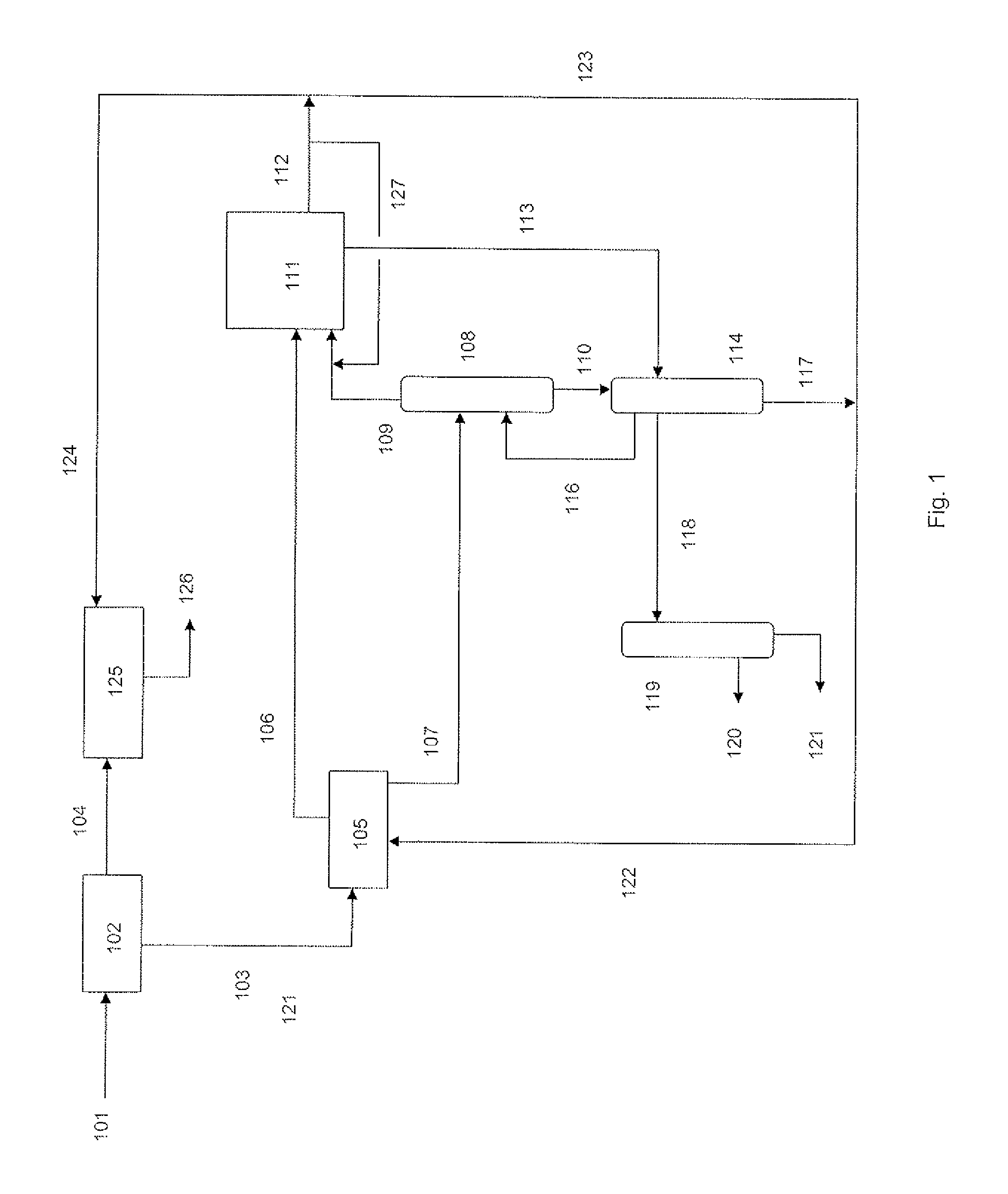

Combined first and second generation biofuels process

A process to integrate a first biofuels process and a second generation cellulosic biofuels process is provided. The pyrolysis means which produces the char stream and a bioliquid stream. The low pressure hydrotreating component, a high pressure hydrotreating component, the low pressure hydrotreating component which produces the hydrocarbon stream, the high pressure hydrotreating component which produces the steam stream and bioliquid stream. A distillation means, which produces a green gasoline stream and a green diesel stream from the bioliquid stream. The second biofuels process may be a first generation bio-ethanol process, which produces a bio-ethanol stream. The hydrogen production unit, which produces the hydrogen stream and the steam stream. The hydrogen production unit may be a steam reformer or partial oxidation unit.

Owner:AIR LIQUIDE LARGE INDS U S LP

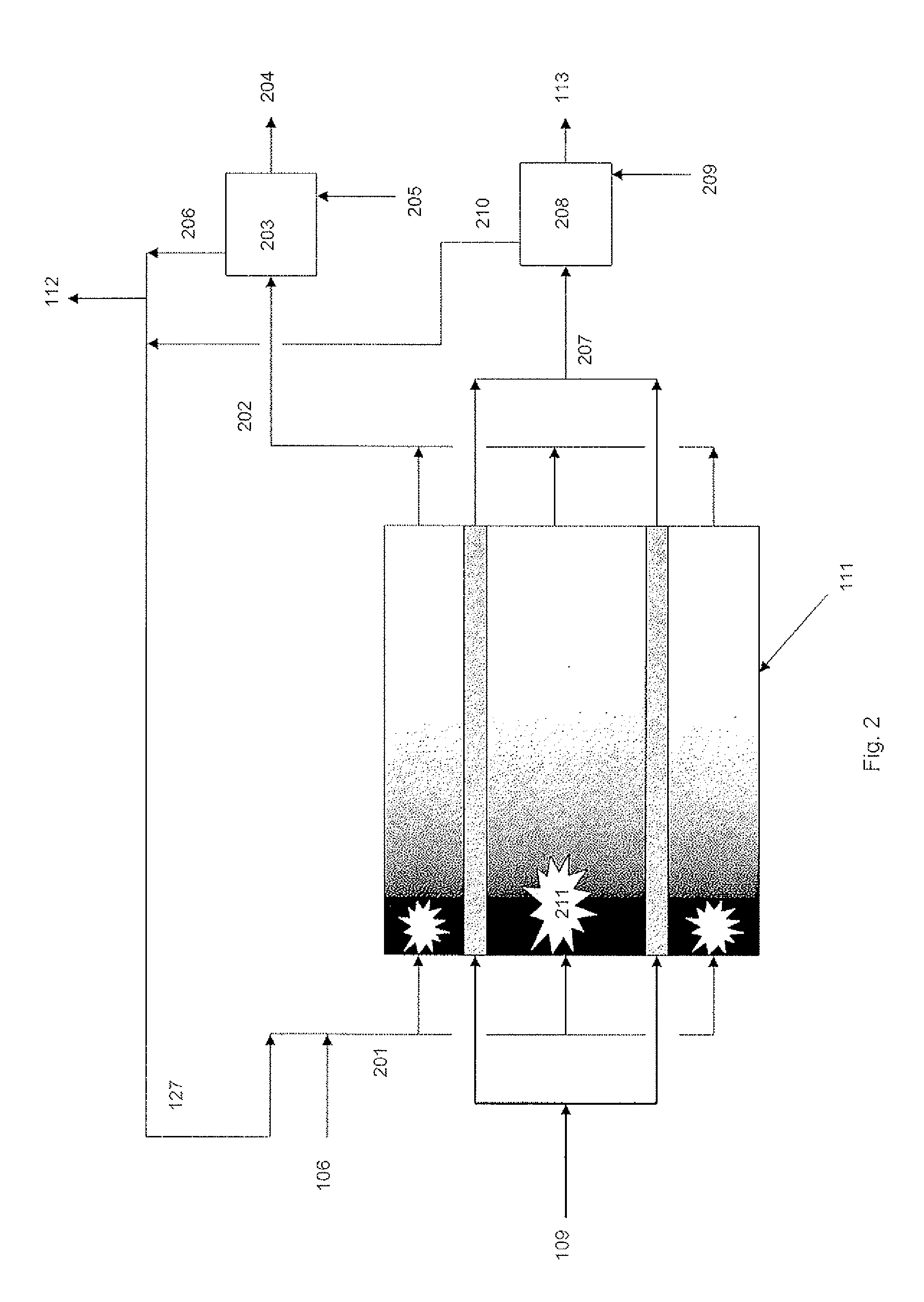

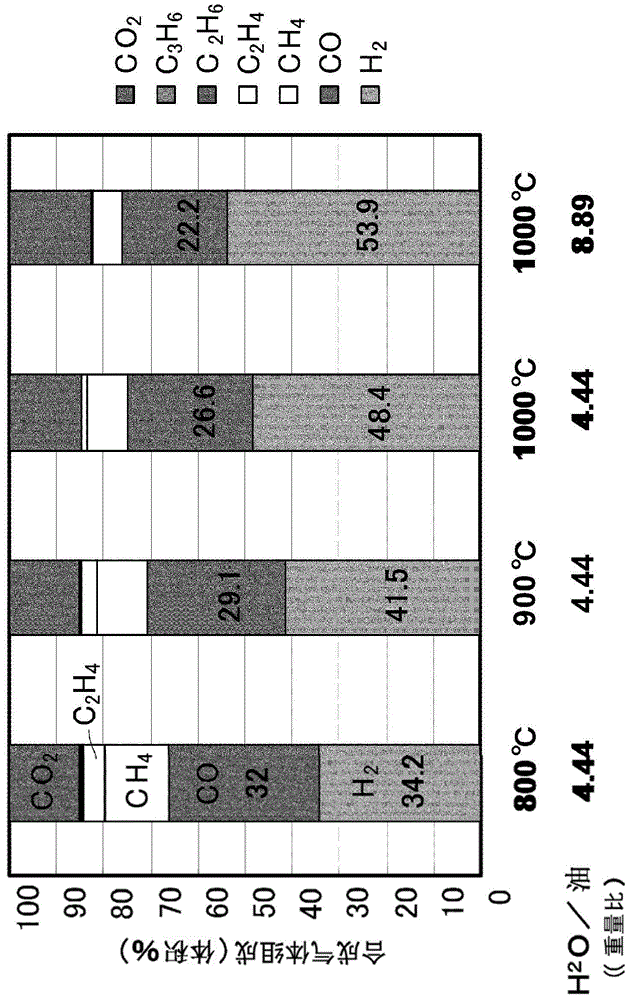

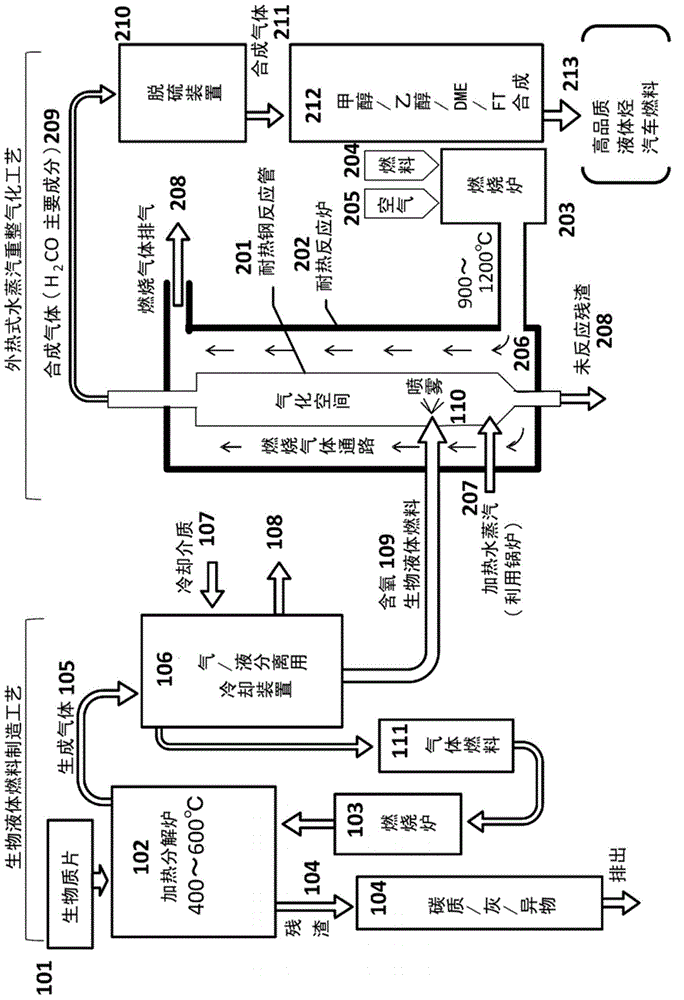

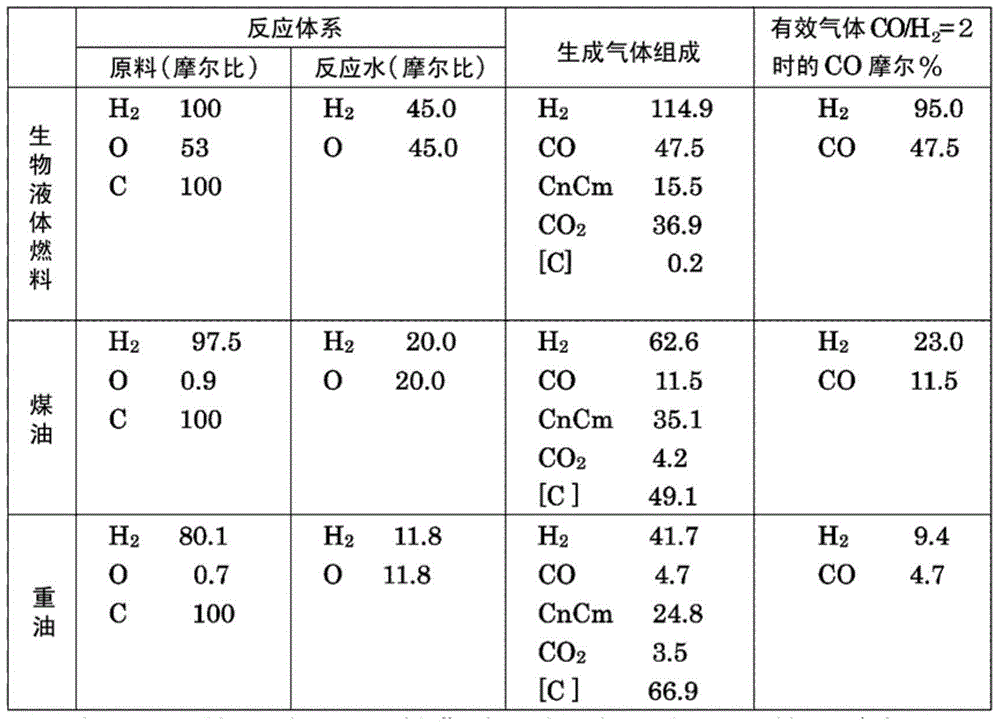

Method and device for producing synthetic gas and method and device for synthesizing liquid fuel

InactiveCN104159845AEasy to handleEasy to collectDirect heating destructive distillationBiofuelsSteam reformingForming gas

Provided is a method for producing synthetic gas with which a virtually soot-free synthetic gas having a good composition can be efficiently obtained by a simple device using a liquid biofuel as the starting material, and it is thereby possible to produce a high-quality liquid fuel such as methanol, gasoline or kerosene. Steam and a liquid biofuel produced by pyrolysis of a biomass are fed to the gasification space inside a reactor tube that is not loaded with a catalyst inside the reactor tube and heated to 800 to 1,200ºC from the outside via the reactor tube walls to induce an endothermic reaction and thereby a steam reforming chemical reaction between the steam and the liquid biofuel. By setting the molar ratio of the fed steam and carbon in the liquid biofuel ([H2O] / [C]) at 0.3 or higher, a synthetic gas having a good composition that is virtually free of tar and soot and is primarily H2 and CO is obtained.

Owner:NAGASAKI INSTITUTE OF APPLIED SCIENCE +2

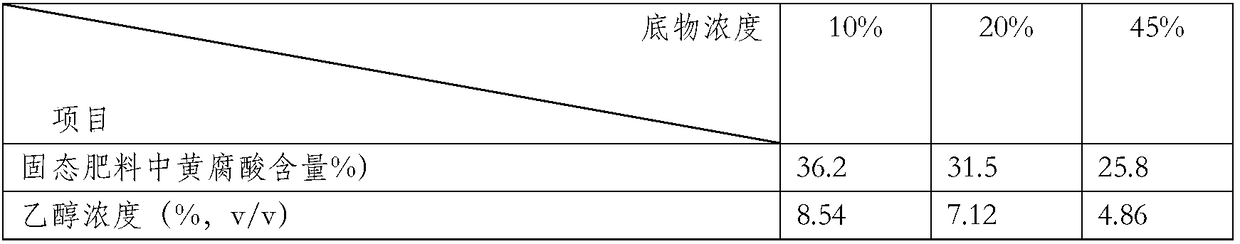

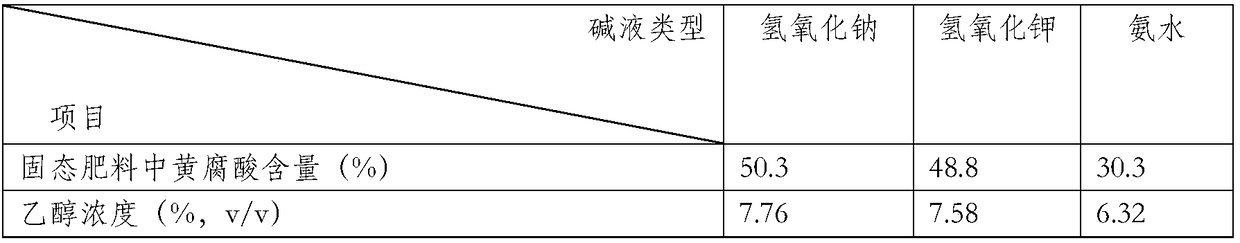

Method for producing biology liquid fuel through biomasses

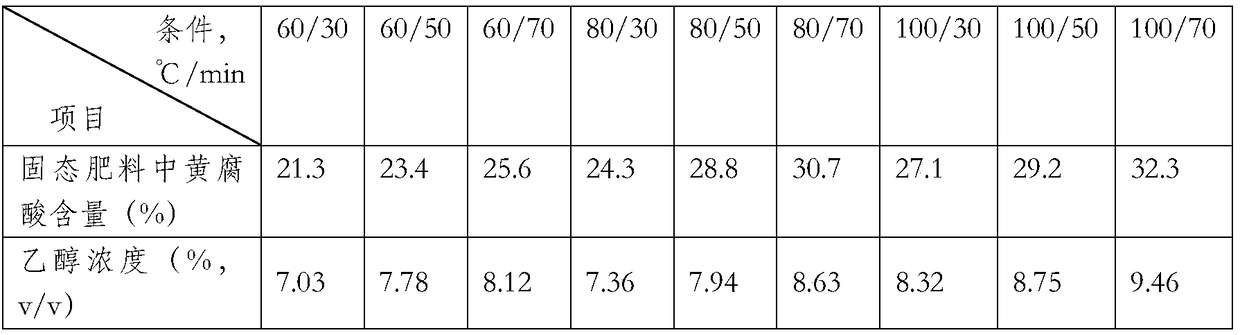

PendingCN109402196AImprove economyReduce consumptionBiofuelsBioloigcal waste fertilisersCelluloseHigh concentration

The invention provides a method for producing biology liquid fuel through biomasses. A high value-added solid fertilizer or a liquid fertilizer can be obtained while the biology liquid fuel with the high concentration is prepared. The method at least includes the steps that sulfite or hydrosulphite are added into biomass raw materials, the mixture is heated for cooking, the cooked materials are subjected to solid-liquid separation to obtain a liquid phase and a solid phase containing cellulose, an auxiliary material is added into the liquid phase to form the solid fertilizer or the liquid fertilizer, an enzyme preparation is added into the solid phase containing the cellulose for hydrolysis and sugar production, and the biology liquid fuel is obtained through fermentation of strains into asugar solution. The method for producing the biology liquid fuel through the biomasses can be used in joint production of the biology liquid fuel and organic fertilizers, and has broad application prospects.

Owner:GUOTOU BIO TECH INVESTMENT CO LTD

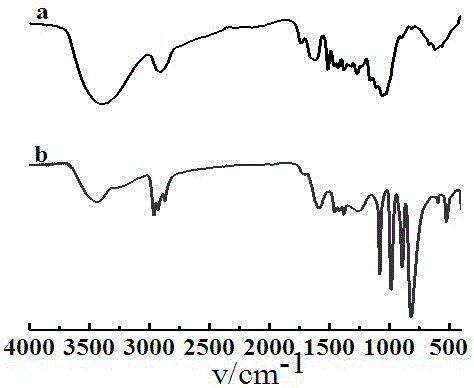

A method for supercritical fluid catalyzed liquefaction of plant raw materials

ActiveCN103555353BIncrease liquefaction rateReduce pollutionLiquid hydrocarbon mixture productionPtru catalystHeteropoly acid

The invention discloses a method for supercritical fluid catalyzed liquefaction of plant raw materials, which comprises the following steps: (1) crushing the plant raw materials, passing through a 40-60 mesh sieve, and drying; (2) adding plant raw materials and Alcohol solvent, using solid heteropoly acid as a catalyst, reacting in a supercritical state for 10-50 minutes, washing out the liquefied product with absolute ethanol, and obtaining biomass oil through suction filtration and rotary evaporation. The invention can greatly improve the liquefaction rate of plant raw materials; use solid heteropolyacid as a catalyst to replace traditional liquid strong acid catalysts such as H2SO4, HCl, HNO3, etc., and has the advantages of less environmental pollution, no corrosion of equipment, and easy separation; the obtained The content of esters in biomass oil is high, especially the content of levulinic acid ester is as high as 20.82%. It can be directly used as gasoline additives and biological liquid fuels. It has the advantages of non-toxicity, high lubricity, and high calorific value. It is a kind of clean energy .

Owner:FUJIAN AGRI & FORESTRY UNIV

Special gasification burner for biological liquid fuel and combustion method

Owner:中天新能源农业科技投资有限公司

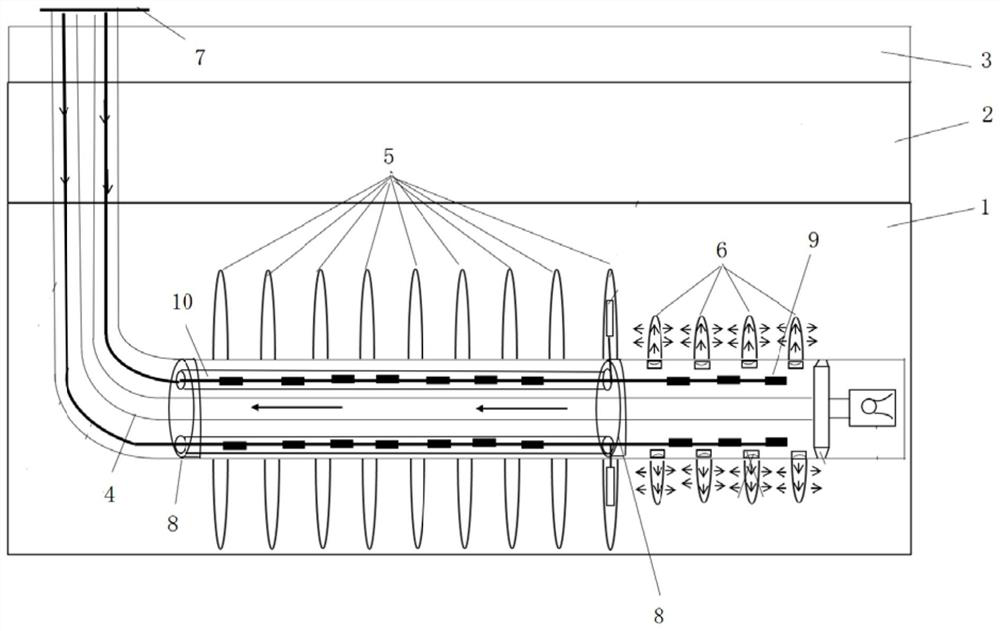

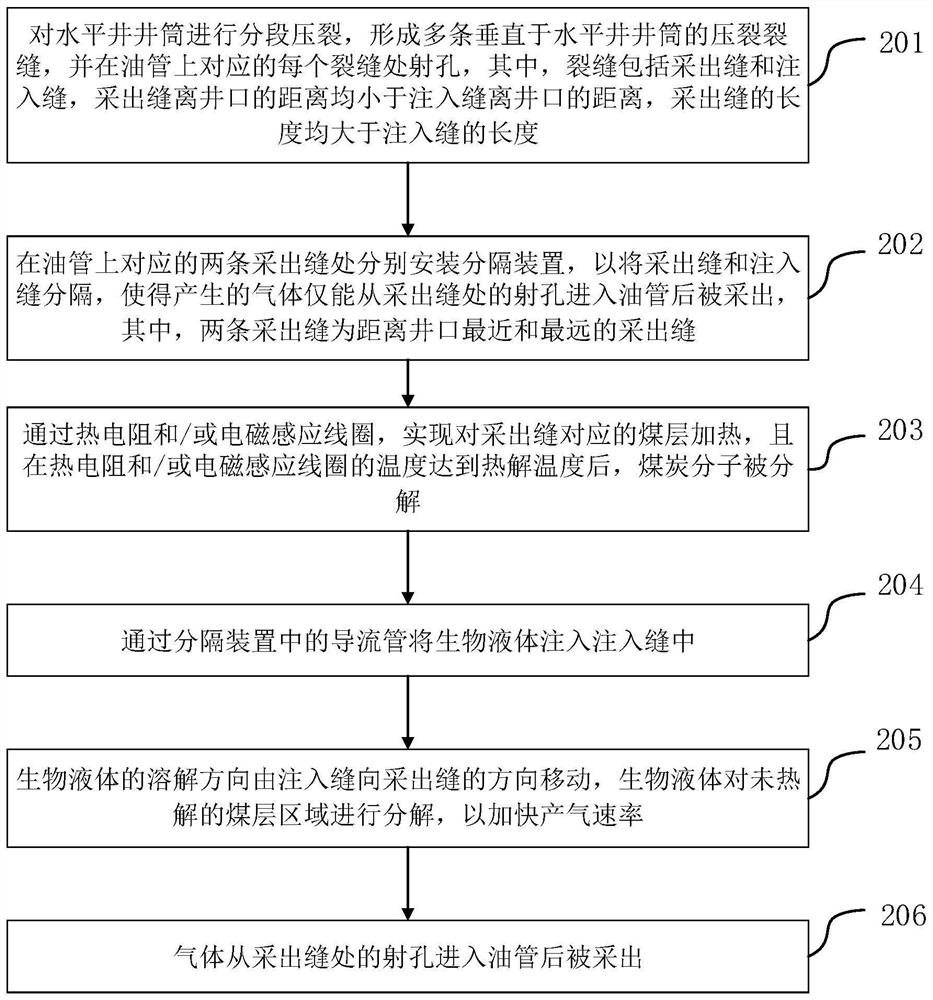

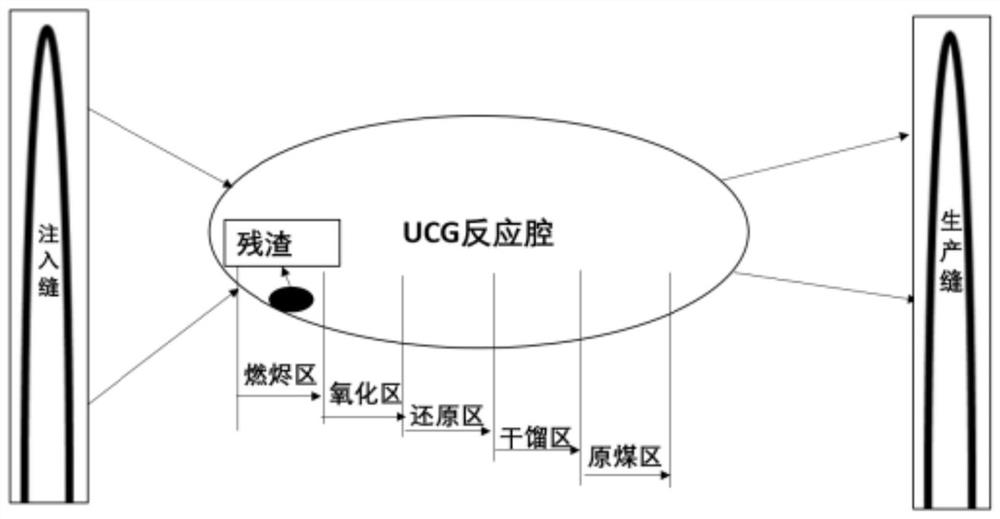

Method and processor for in-situ conversion between same well sections of coal seam horizontal well

PendingCN113669045AReduce distanceIncrease the number ofConstructionsFluid removalThermodynamicsHorizontal wells

The invention relates to a coal mining technology, and discloses a method and a processor for in-situ conversion between same well sections of a coal seam horizontal well. An oil pipe is arranged in the horizontal well. The method comprises the following steps of: performing staged fracturing on a horizontal well shaft to form a plurality of fracturing cracks perpendicular to the horizontal well shaft, and perforating at each corresponding crack on the oil pipe, wherein the cracks comprise production cracks and injection cracks, the distance between each production crack and a well mouth is smaller than the distance between each injection crack and the well mouth, and the length of each production crack is greater than the length of each injection crack; mounting separation devices at two corresponding production cracks on the oil pipe; heating coal seams corresponding to the production cracks through thermal resistors and / or electromagnetic induction coils; injecting biological liquid into the injection cracks through flow guide pipes in the separation devices; moving the dissolution direction of the biological liquid from the injection cracks to the production cracks, and decomposing a non-pyrolyzed coal seam area by the biological liquid; and enabling gas to enter the oil pipe from perforations at the production cracks and then be produced. Therefore, the number of development wells is reduced, and the development efficiency is improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Biological liquid fuel oil produced by wax of rice bran, and preparation method

InactiveCN101050384ANo pollution in the processImprove atomization effectTreatment with plural serial stages onlyLiquid carbonaceous fuelsCatalytic pyrolysisMolecular sieve

This invention relates to a method for preparing biological liquid fuel oil from rice bran wax. The biological liquid fuel oil is prepared from rice bran wax and antioxidant (0.01-0.5 wt. %). The method comprises: performing catalytic pyrolysis and catalytic fractionation on rice bran wax in the presence of petroleum pyrolysis catalyst, decoloring with 3A molecular sieve, and adding the antioxidant. The obtained biological liquid fuel oil is similar to mineral oil in the properties, and has such advantages as good atomization effect, adequate combustion, easy cold start in winter, no need for combination with other fuels, low cost, and simple process.

Owner:李光

Method for preparing sugar alcohol ethylation biology liquid fuel

The invention discloses a method for preparing sugar alcohol ethylation biology liquid fuel, and belongs to the field of fuels. The method includes the following steps: mixing sucrose, mannitol and glycerin; adding sodium hydroxide and monochloroethane for reaction; enabling the mixture after reaction to be subjected to standing; adjusting the pH value of the supernatant, and then adding trichloromethane in the supernatant to obtain ethylation mixed liquor; taking fruits of cornus wilsoniana, and obtaining the bio-oil of fruits of cornus wilsoniana after processes of soaking with n-butyl alcohol, grinding, filtration, and the like; mixing a catalyst prepared from calcium oxide with the bio-oil, so as to obtain hydrocarbon-enriched bio-oil; mixing the ethylation mixed liquor with the hydrocarbon-enriched bio-oil to obtain the sugar alcohol ethylation biology liquid fuel. According to the invention, sucrose, mannitol and monochloroethane (an etherifying agent) is successfully subjected to one-step reaction to realize liquidation of oligosaccharide and sugar alcohol without generating gaseous by-product, besides, the ethylation of glycerin changes fluidity and combustion performance of glycerin, and the bio-oil generated by cornus wilsoniana is added, so that the condensation point of the fuel is reduced.

Owner:梅庆波

A kind of biological liquid organic fertilizer and preparation method thereof

InactiveCN102531714BEliminate Pollution PotentialReduce alkalinityBio-organic fraction processingWaste based fuelBiologyBacilli

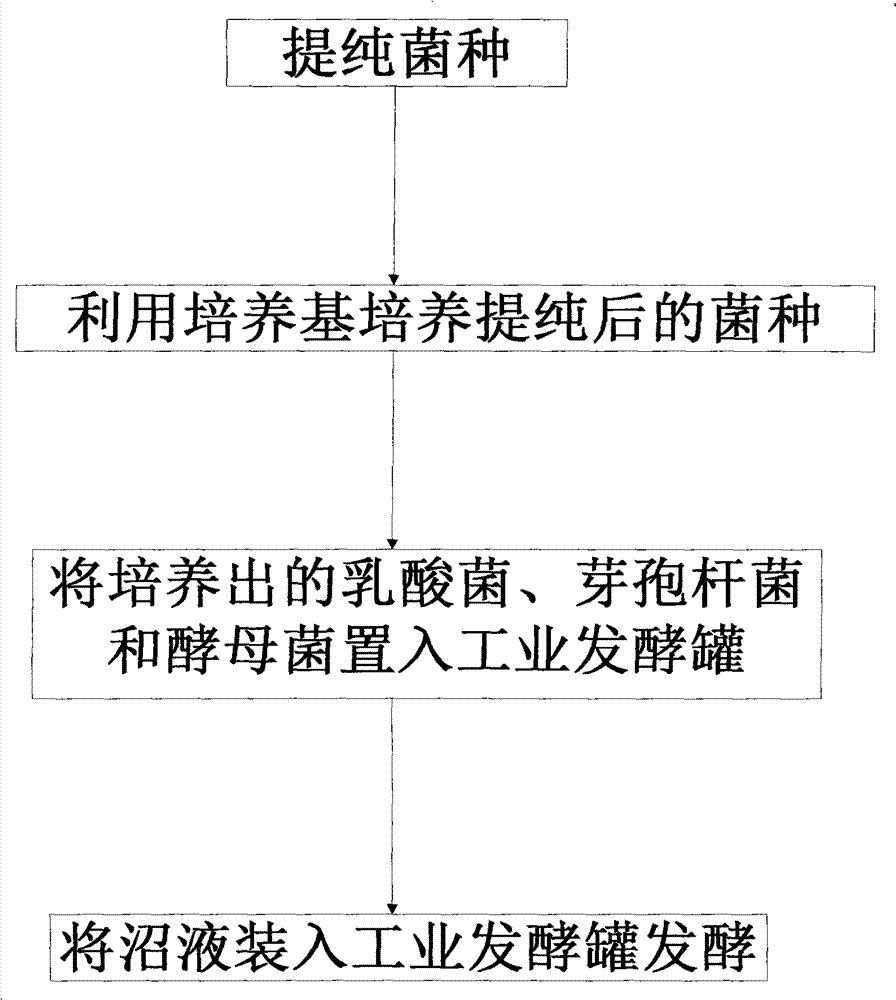

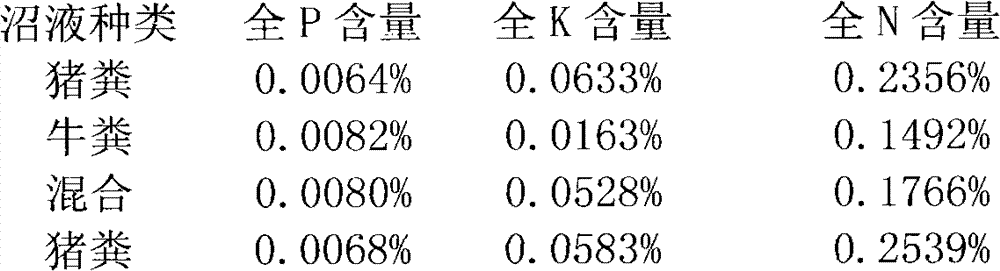

The invention discloses a biological liquid organic fertilizer and a preparation method thereof, belonging to the field of microbial fermentation. According to the preparation method, biogas slurry and biogas residue generated by a biogas digester are taken as a culture medium, lactic acid bacteria, bacillus and yeast are taken as beneficial microflora, the culture medium is used for culturing the beneficial microflora, and the biogas slurry, the biogas residue and the beneficial microflora are fermented for 72-96 hours in an industrial fermentation tank, wherein the fermentation temperature is at 60-70 DEG C. After the biogas slurry is prepared into the concentrated liquid high-efficient biological organic fertilizer, the concentrated liquid high-efficient biological organic fertilizer can be transported in a larger region, can be convenient to use and has the advantages of upgraded effect and reduced cost and the pollution hidden trouble caused by direct use of the biogas slurry is eliminated. The biological liquid organic fertilizer prepared by the method can reduce the alkalinity of soil, avoid the generation of white nitrate on the surface of land, loosen and soften soil so that the soil has good air permeability; moreover through application of the biological liquid organic fertilizer, crops can grow uniformly and vigorously the yield increasing effect is very obvious.

Owner:BEIJING HANHUA UNITED ENVIRONMENTAL PROTECTION TECH CENT

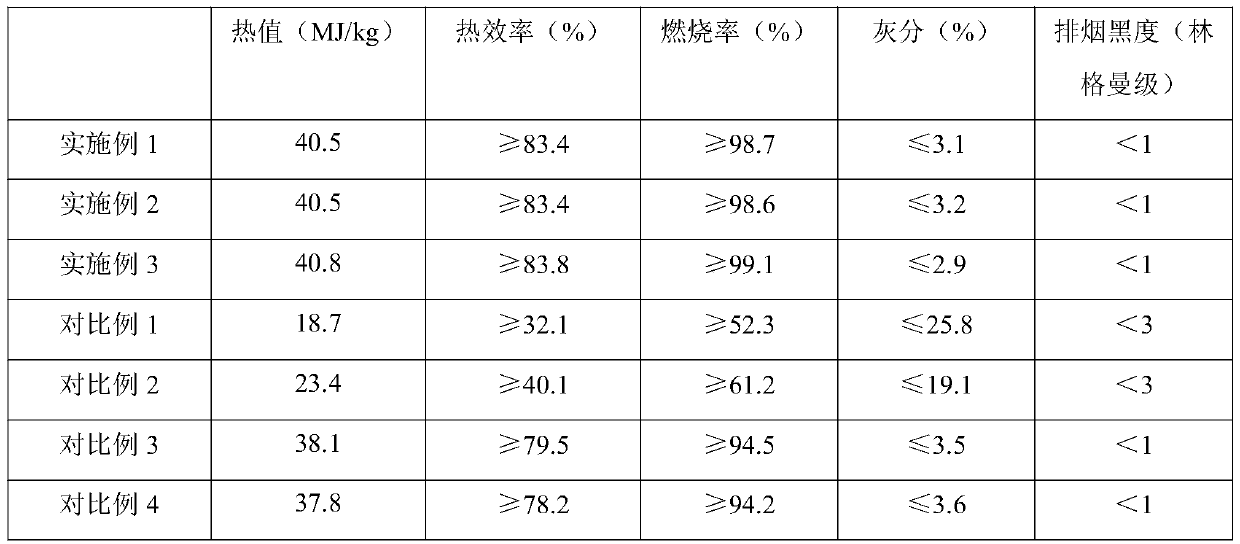

A kind of environment-friendly biological liquid fuel and preparation method thereof

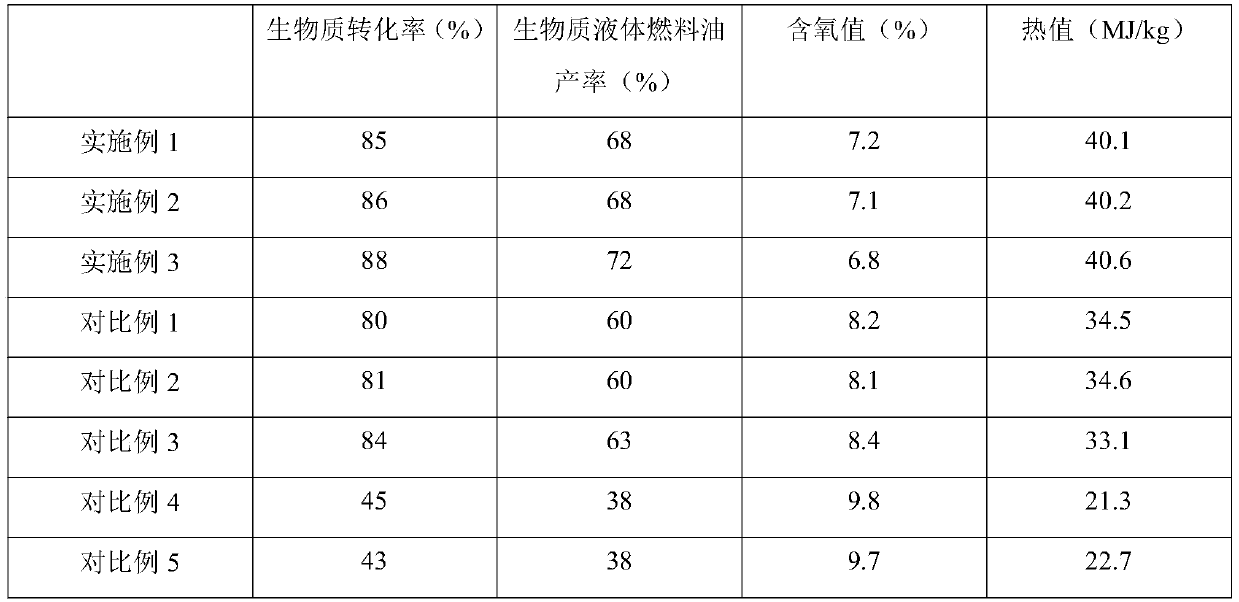

InactiveCN107446631BHigh biomass conversion ratePromote environmental protectionLiquid carbonaceous fuelsEnvironmental engineeringLiquid fuel

The invention provides environment-friendly biological liquid fuel and a preparation method of the liquid fuel. The environment-friendly biological liquid fuel is prepared by the steps of biomass pretreatment, first crack, second crack, fractionation and combustion reaction kettle reaction. The biomass conversion rate is higher, and the environmental friendliness is better. The biomass of the fuel comprises two parts: cottonseed hulls, bagasse, walnut shells and chestnut shells at a specific proportion as one part, and carrageen and ulva at a specific proportion as the other part; in a crack and conversion process of the biomass, different internal ingredients are fused mutually; and effective conversion of the biomass is promoted. The crack temperature is increased from the first crack to the second crack; the sufficient conversion of the biomass is facilitated; tar and the like are not generated in the crack process; and the environmental friendliness is better.

Owner:鑫英兰能源科技发展如皋有限公司

An organic fertilizer method that promotes the firing of smoke and grow up early and grows with water and fertilizer.

ActiveCN107027493BImprove stress resistanceRich in trace elementsAnimal corpse fertilisersGrowth substratesNutrient solutionPest control

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH

A kind of preparation method of low-viscosity carbon deposition-reduced fuel oil

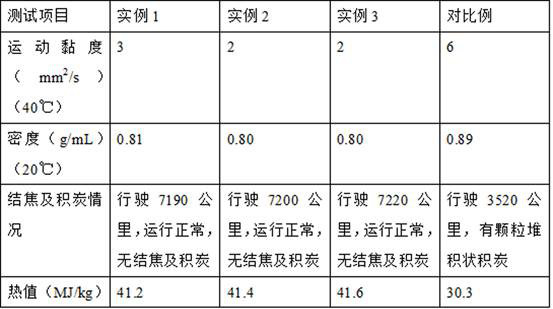

ActiveCN108929730BHigh carbon contentEmulsify and disperseLiquid carbonaceous fuelsFuel additivesIsobutanolO-Phosphoric Acid

The invention discloses a preparation method of low-viscosity carbon deposit-reducing fuel oil, and belongs to the technical field of new energy production. In the method, high-calorific value liquidbio-fuel oil is produced from chlorella, which has an obvious single-cell protein nucleus; with biogas slurry, shell powder and the like wastes being culture substrate, atomized dispersion liquid is prepared from ethanol trimer, ethylene glycol monobutyl ether, octadecyl sulfobetaine and the like, wherein the octadecyl sulfobetaine has certain cleaning performance on tar; V2O5, isobutanol and benzyl alcohol are used as raw materials and are subjected to a heating reaction in a phosphoric acid solution; methanol and isopropanol serve as a dispersion liquid; before combustion, magnesium powder can be subjected to oxidization complexing with sodium polyphosphate and triethanolamine through preheating, thus forming an oleophobic protective layer for reducing deposition of a residual carbon layer during the combustion of the fuel oil, magnesium being reduced into the magnesium powder; according to such circulating reaction with the residual carbon layer, the deposition of the residual carbon layer can be reduced. The method has extensive application prospect.

Owner:江西瑞府环保石化有限公司

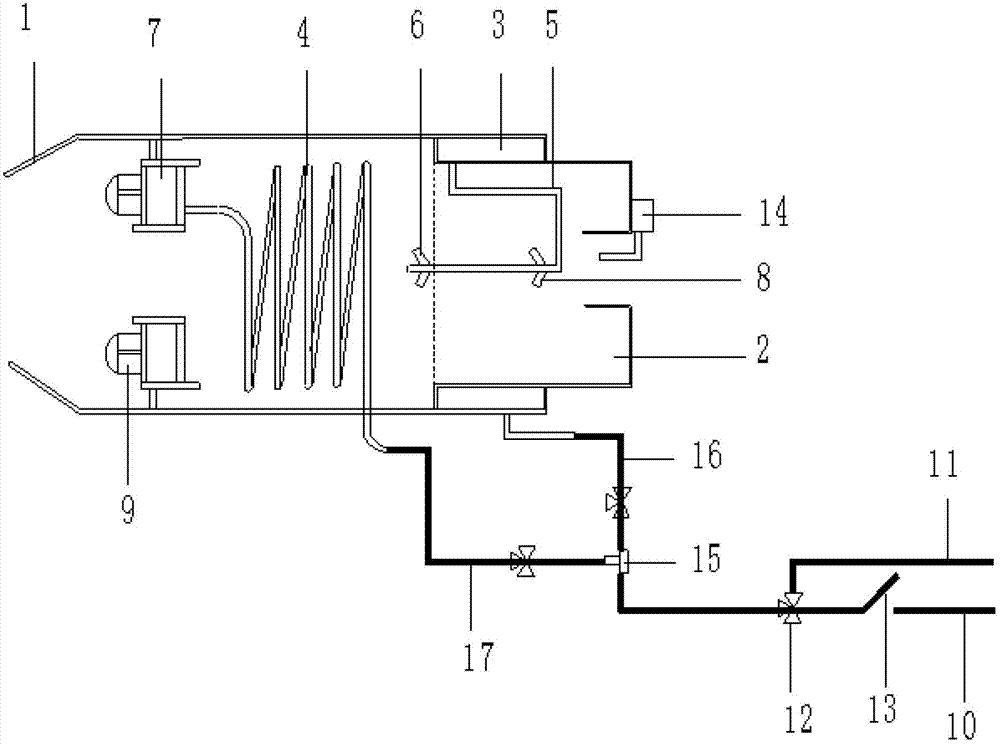

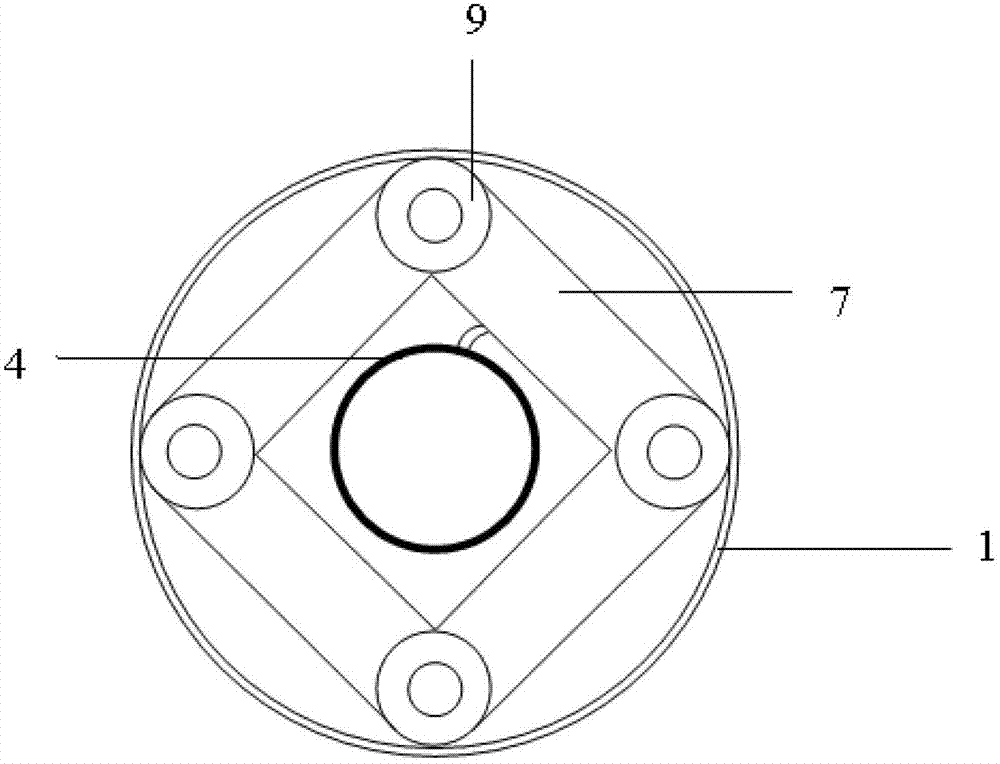

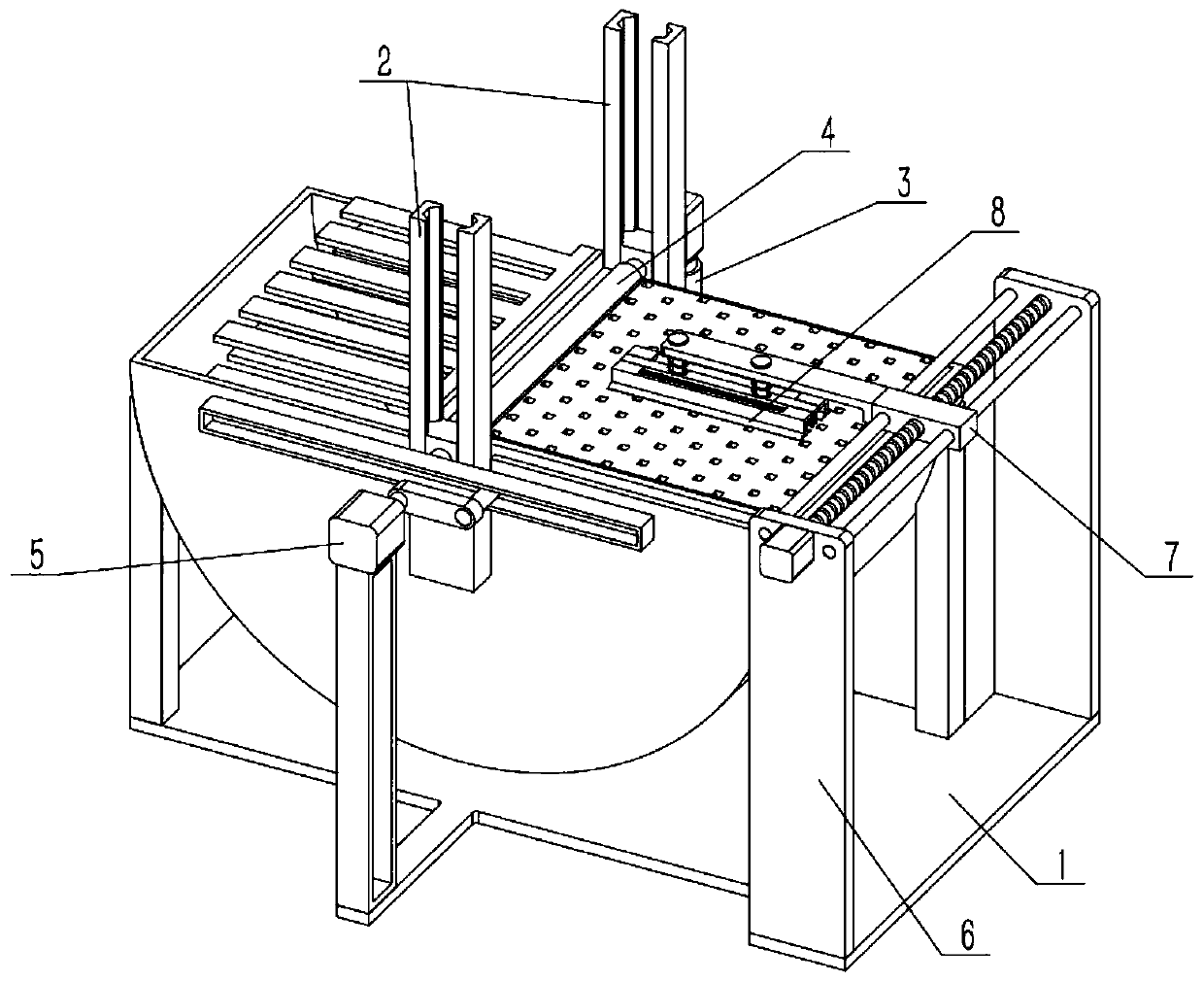

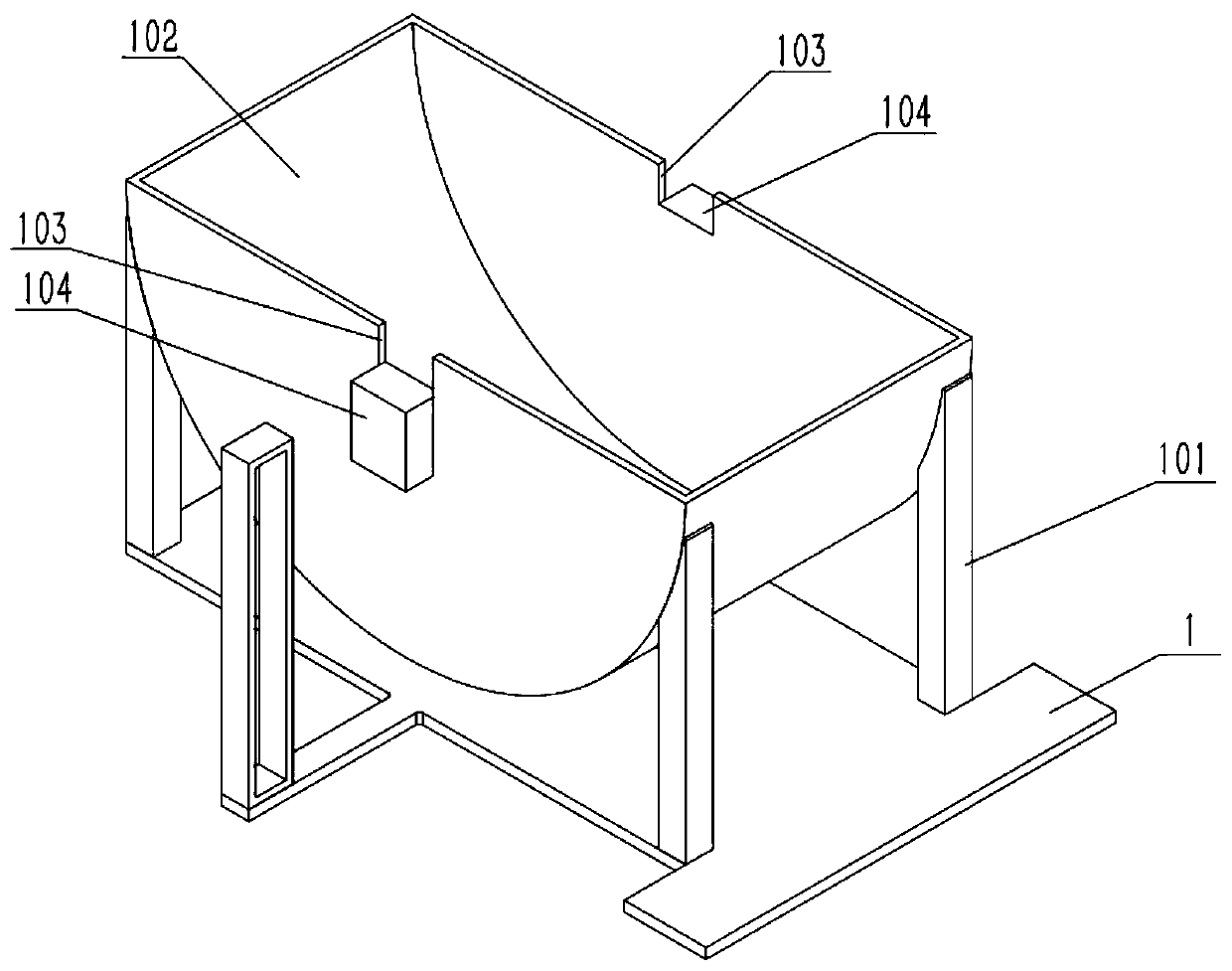

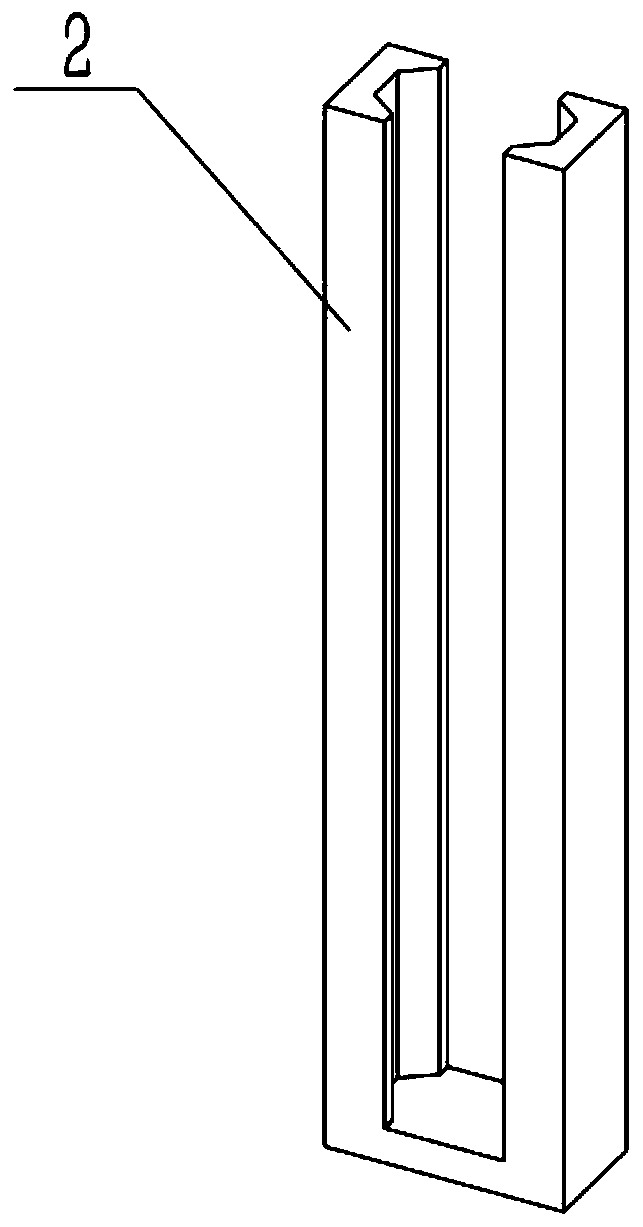

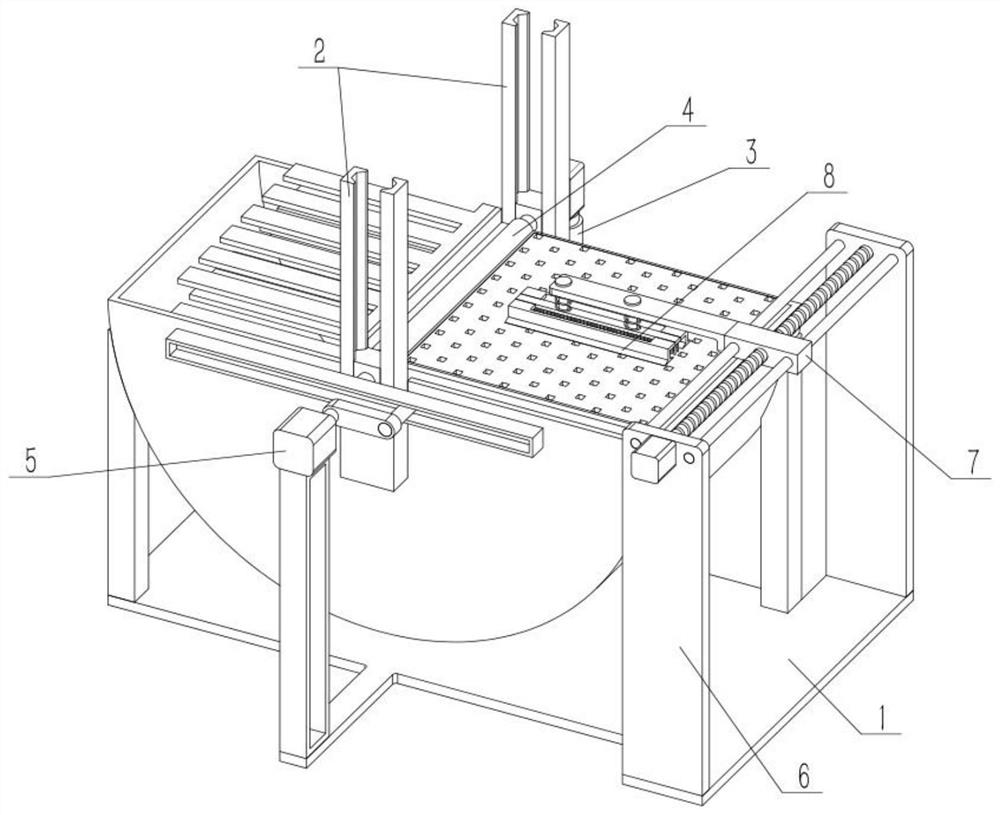

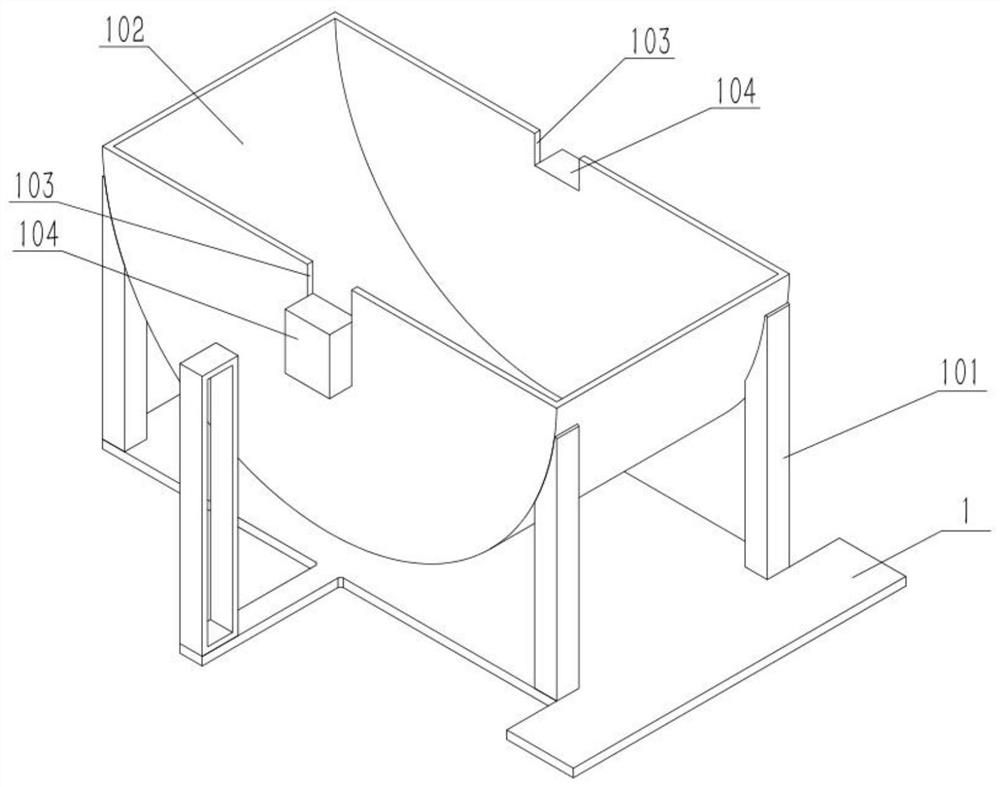

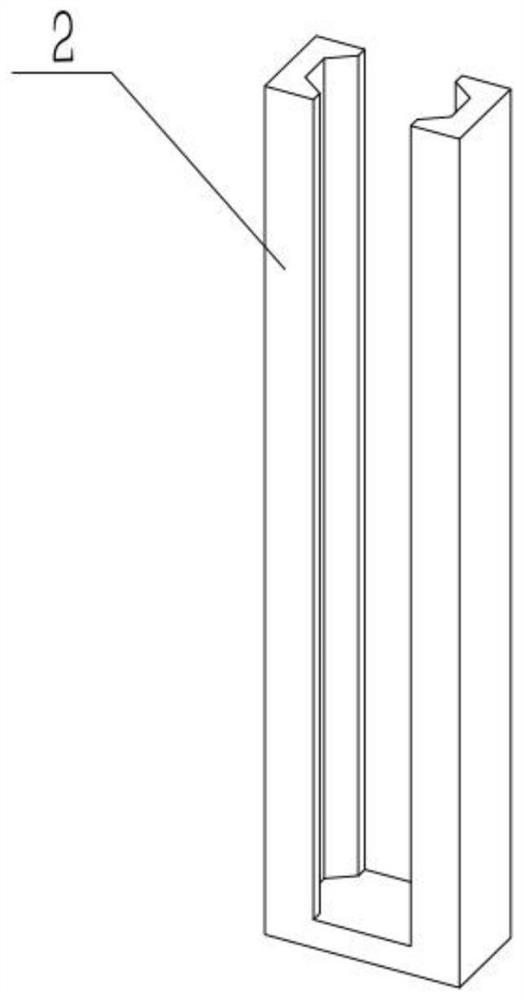

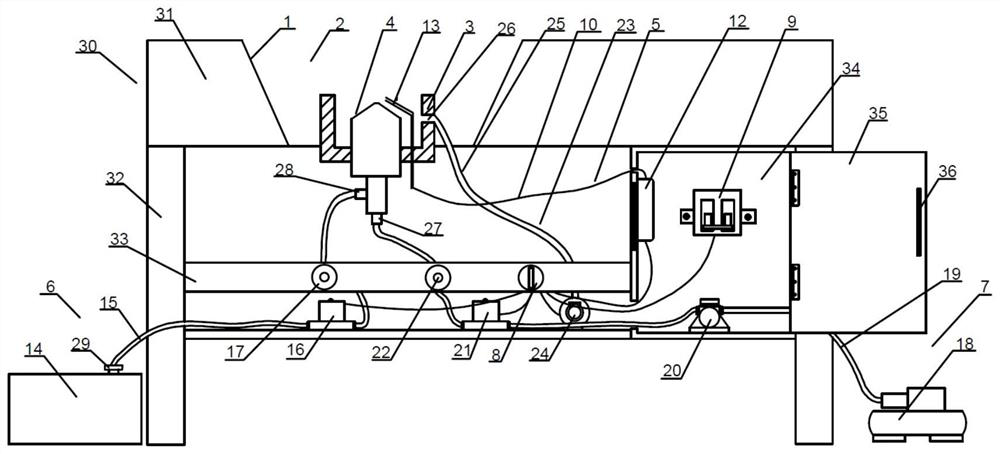

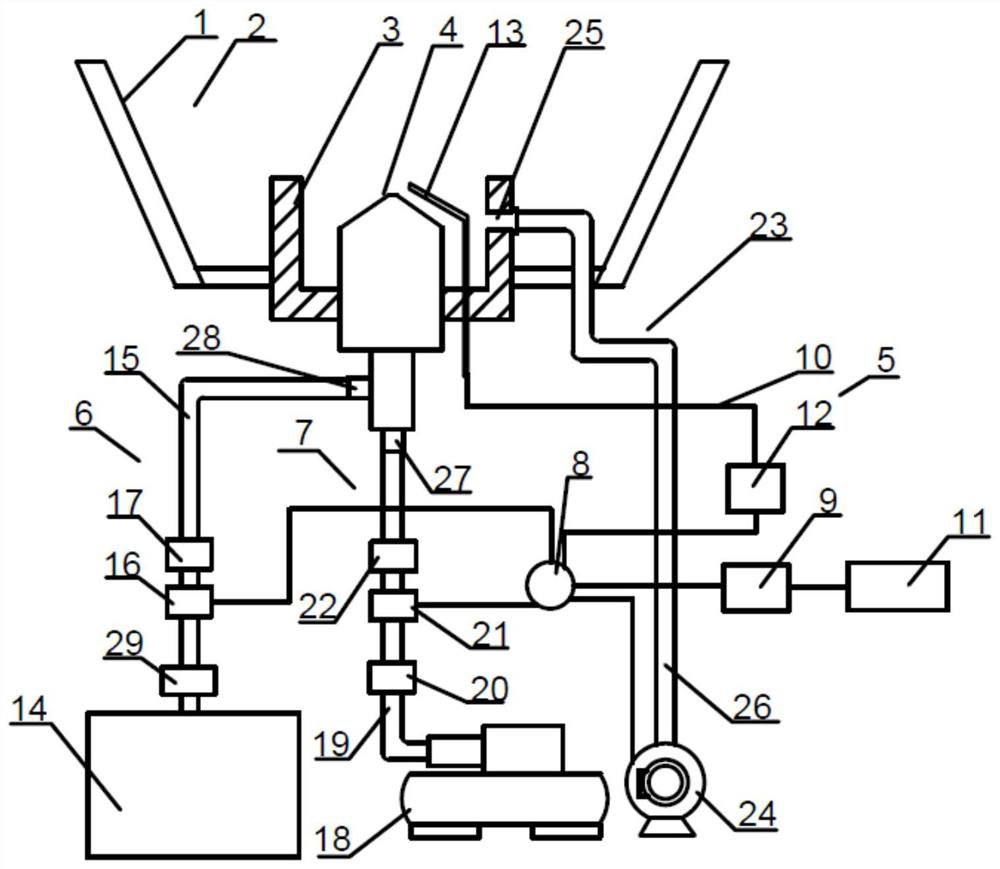

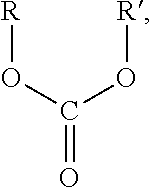

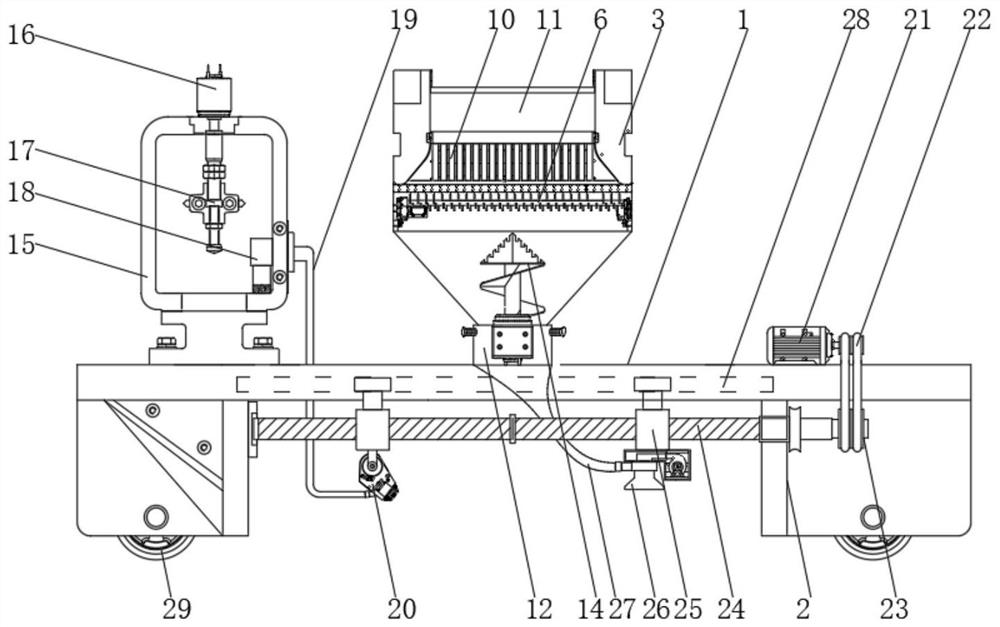

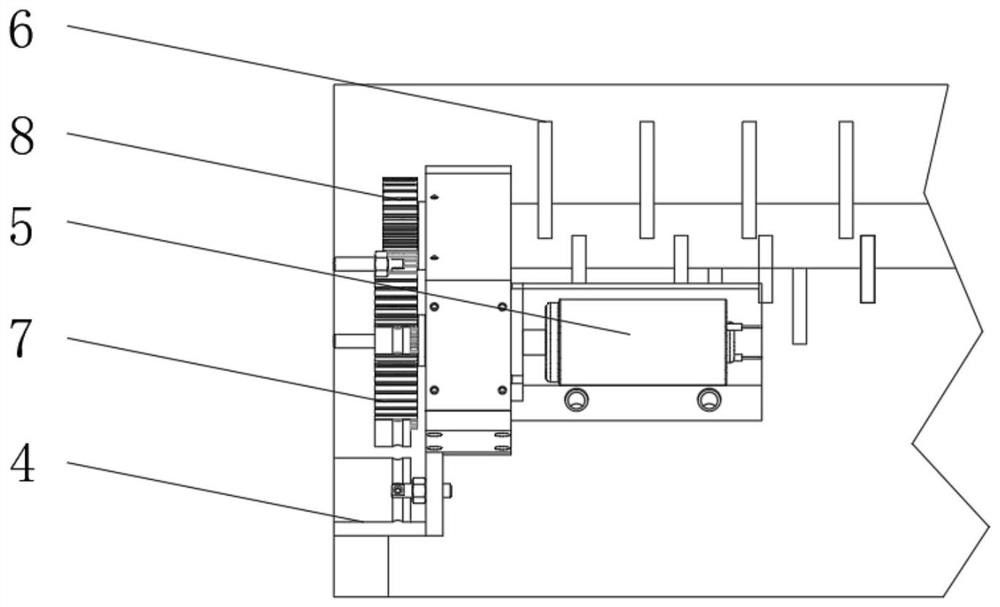

Biological liquid fuel and preparation system and method thereof

ActiveCN111408298AShaking/oscillating/vibrating mixersTransportation and packagingEngineeringLiquid fuel

The invention relates to preparation of biological liquid fuel, in particular to biological liquid fuel and a preparation system and method thereof. The system comprises a base, a stand column, a preparation box, a sleeve, a filter screen and a first stirring blade, and the operation mode of the system is controlled by changing the relative position of a connecting shaft and a transmission frame rotating center. When the highest position of the connecting shaft is positioned below the rotating center of the transmission frame, the connecting shaft drives the transmission frame to swing, so that the first stirring blade can swing back and forth to realize high-frequency stirring operation; when the rotating center of the connecting shaft and the rotating center of the transmission frame areat the same height, the transmission frame rotates by a circle to enter and exit a primary preparation box to bring out primary impurities, and the first stirring blade enters and exits the primary preparation box to perform primary stirring, so that stirring operation and filtering operation are synchronously performed.

Owner:贵州六维新能源股份有限公司

Methods and apparatus for controlling moisture in plant oils and liquid biofuels

InactiveUS9028697B2Promote hydrolysisGood hygroscopicityFatty oils/acids recovery from wasteLiquid separation auxillary apparatusBiodieselFuel tank

The moisture absorption capacity of biofuels can be more or less 10 times that of fossil diesel oil, causing biofuels to form acids that induce metal corrosion and form deposits in the fuel tank and pipe lines. Methods for removing moisture from stored biofuels and plant oils are described wherein glycerol is used as a solvent to extract the moisture from the bioliquid or oil, comprising the steps of placing the biofuel or oil in fluid contact with glycerol, incubating for a time, and then removing the glycerol. A cellulous ester dialysis or other semi-permeable membrane may be used to prevent the glycerol from contaminating the biofuel while allowing moisture to pass. Crude glycerol produced as a byproduct of biodiesel production may be used in the method of the disclosed invention with good result. Preferred embodiments of apparatus that employ the method of the subject invention are described.

Owner:MATSUMURA MASATOSHI

A kind of low-carbon high-efficiency biological liquid fuel and preparation method thereof

InactiveCN107699268BLow-carbon and high-efficiency combustionEfficient conversionLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionLiquid fuelCarbon deposit

The invention provides a low-carbon efficient biological liquid fuel and a preparation method thereof. In the invention, a biomass raw material is made into a crushed mixture and then the crushed mixture is pyrolyzed to obtain a biomass pyrolysis liquid, the biomass pyrolysis liquid is then mixed and stirred with a fermentation liquid prepared from palm residue to obtain a first mixture, propyleneglycol is mixed with n-heptane to prepare a second mixture, and finally the first mixture and the second mixture are mixed to obtain the biological liquid fuel which has low-carbon and high-efficiency combustion performance. The biomass raw material employed in the preparation method adopts rice hulls, cypress leaves, hemp stem, tung tree branches and pine cones with a specific ratio. During thepyrolysis and transformation process of the raw materials, various internal components co-operate to promote effective conversion of biomass and optimize the flowing performance of the biological liquid fuel, thereby promoting efficient fuel conversion and reduce carbon deposition.

Owner:中醇(北京)能源有限公司

Method for manufacturing bio-liquid fuel

PendingCN111212890AEfficient preparation methodFatty acid esterificationPreparation by ester-hydroxy reactionPtru catalystPhysical chemistry

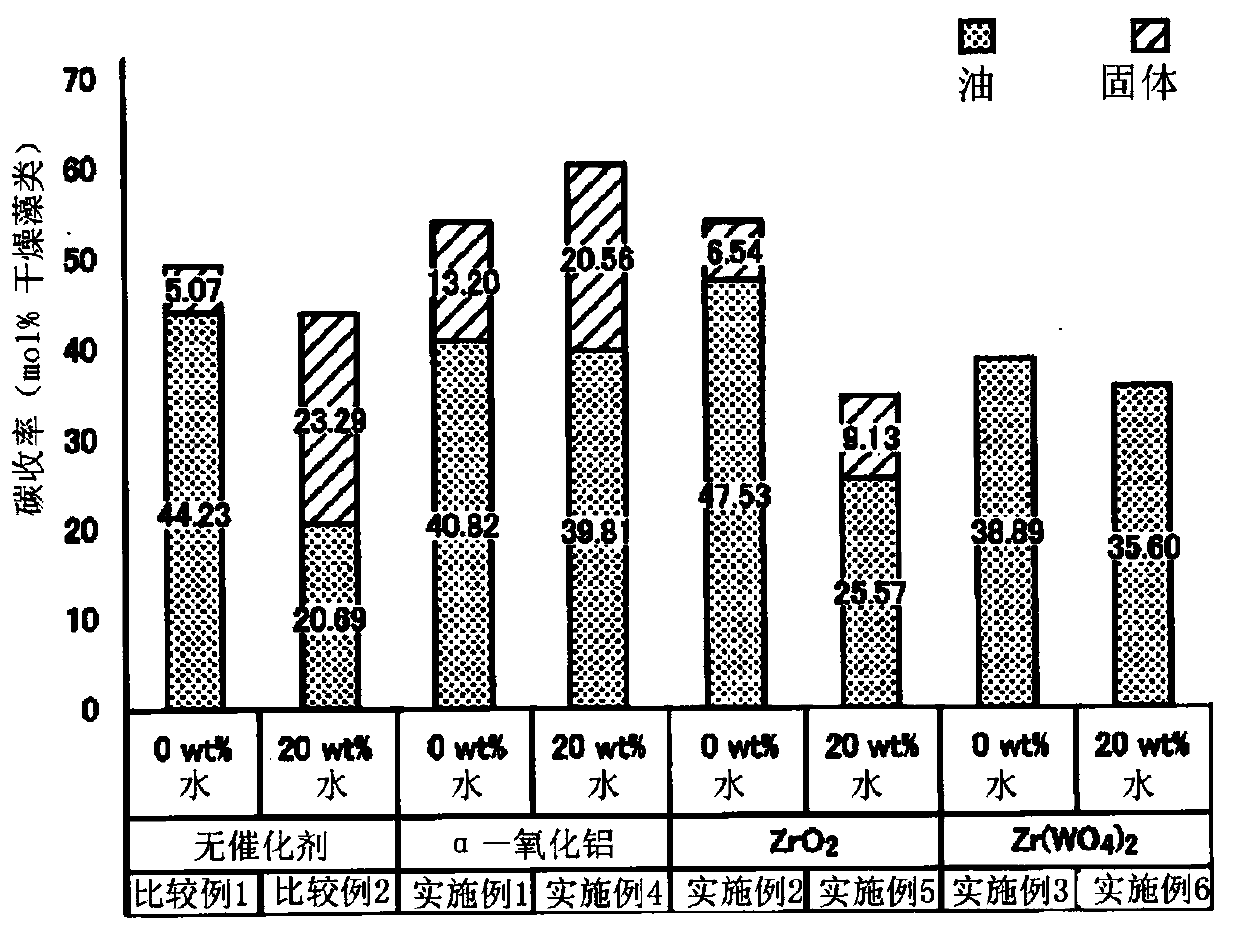

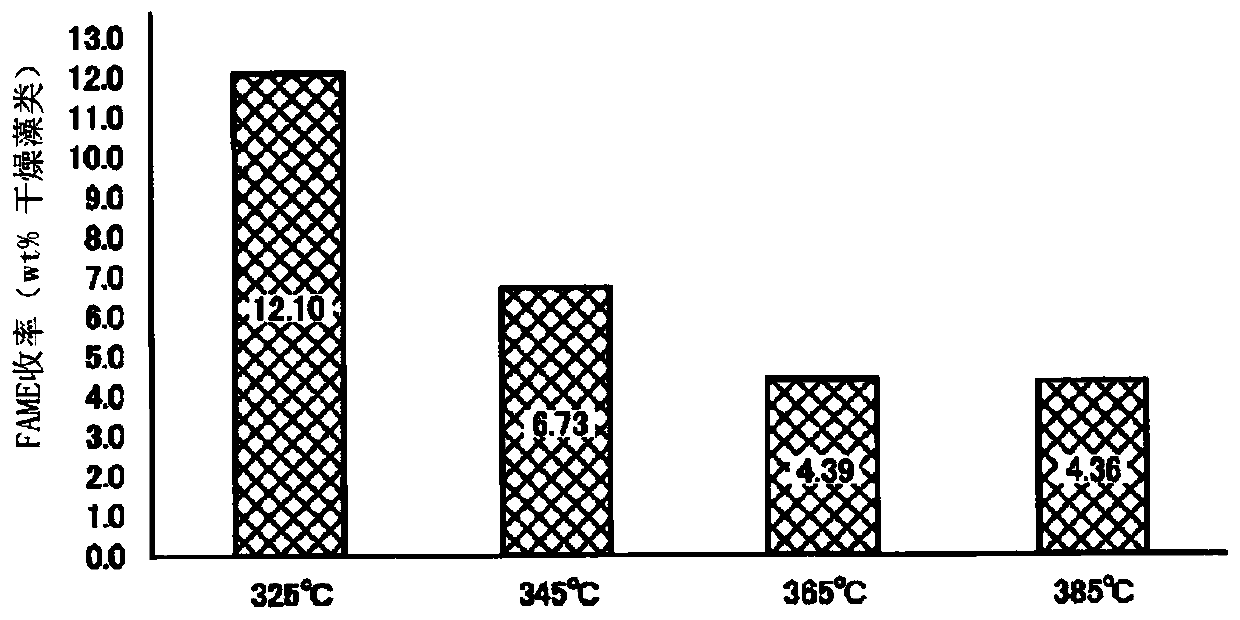

A method for manufacturing a bio-liquid fuel, said method comprising contacting oil-containing microalgae with supercritical or subcritical methanol or supercritical or subcritical ethanol in the presence of a catalyst which is an oxide containing at least one kind of metal selected from the group consisting of metals of groups IIA to IIIA in the periodic table, lanthanoids and actinoids.

Owner:NIPPON SODA CO LTD

A kind of biological liquid fuel and its preparation system and method

Owner:贵州六维新能源股份有限公司

Novel biology liquid fuel cooker

PendingCN111692614ABurn fullyAvoid wastingBurnersLiquid fuel feeder/distributionInjector nozzleLiquid fuel

The invention discloses a novel biology liquid fuel cooker which comprises a cooking bench, a hearth arranged in the cooking bench, a furnace end arranged at the lower part of the hearth, a fuel spraynozzle connected with the lower end of the furnace end, an electric ignition device connected with the furnace end, a fuel supply device capable of adjusting the fuel quantity, a gas supply device capable of adjusting the air pressure and the gas flow rate, a cooker switch and a power-off protection switch; the electric ignition device, the fuel supply device and the gas supply device are electrically connected with the cooker switch through a power line; and the cooker switch is electrically connected with the power-off protection switch electrically connected with a power supply through thepower line. Through the fuel supply device and the gas supply device, the air intake quantity and the fuel intake quantity of the fuel spray nozzle are adjusted to reach the best gas-oil ratio, so that fuel burns more sufficiently and fuel waste is avoided; and the power-off protection switch is adopted to effectively avoid the situation that the cooker has electric leakage to cause danger duringthe using process, so that the cooker safety is greatly improved.

Owner:孙川

Biological liquid fuel oil produced by wax of rice bran, and preparation method

InactiveCN100569922CNo pollution in the processImprove atomization effectTreatment with plural serial stages onlyLiquid carbonaceous fuelsCatalytic pyrolysisMolecular sieve

This invention relates to a method for preparing biological liquid fuel oil from rice bran wax. The biological liquid fuel oil is prepared from rice bran wax and antioxidant (0.01-0.5 wt. %). The method comprises: performing catalytic pyrolysis and catalytic fractionation on rice bran wax in the presence of petroleum pyrolysis catalyst, decoloring with 3A molecular sieve, and adding the antioxidant. The obtained biological liquid fuel oil is similar to mineral oil in the properties, and has such advantages as good atomization effect, adequate combustion, easy cold start in winter, no need for combination with other fuels, low cost, and simple process.

Owner:李光

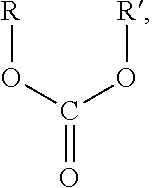

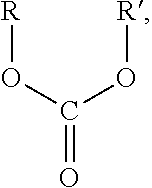

Environmental-friendly liquid fuel and production process thereof

InactiveUS20130305595A1High oxygen contentEnsure complete combustionHeterogenous catalyst chemical elementsCatalyst activation/preparationFuranCycloaddition

The present invention discloses a liquid fuel and production process thereof, the liquid fuel comprises dialkyl carbonates with the structural formula ofwherein R and R′ are same or different, and R and R′ are selected from the group consisting of C1-C8 linear chain alkyl, C3-C8 branched chain alkyl, C3-C8 naphthene base and alkyl containing furan ring. The process of the production of the liquid fuel comprises the steps of: performing a cycloaddition reaction between 2-methyl tetrahydrofuran produced by hydrogenation from furfural which is a biomass derivative and carbon dioxide to produce a cyclic carbonate (i.e. 1,4-pentanediol carbonate), then performing an ester exchange reaction between the cyclic carbonate and monohydric alcohol to produce the dialkyl carbonate. The liquid fuel produced by the present invention is clean, safe and biodegradable; it is compatible with advantages of conventional fossil-based liquid fuels and biological liquid fuels and with a wide range of applications, the process provides a new way for industrial production of the dialkyl carbonate and efficient and comprehensive utilization of biomass resources, the economic and social benefit is remarkable. The present invention discloses a liquid fuel and production process thereof, the liquid fuel comprises dialkyl carbonates with the structural formula ofwherein R and R′ are same or different, and R and R′ are selected from the group consisting of C1-C8 linear chain alkyl, C3-C8 branched chain alkyl, C3-C8 naphthene base and alkyl containing furan ring. The process of the production of the liquid fuel comprises the steps of: performing a cycloaddition reaction between 2-methyl tetrahydrofuran produced by hydrogenation from furfural which is a biomass derivative and carbon dioxide to produce a cyclic carbonate (i.e. 1,4-pentanediol carbonate), then performing an ester exchange reaction between the cyclic carbonate and monohydric alcohol to produce the dialkyl carbonate. The liquid fuel produced is clean, safe and biodegradable, and the process provides a new way for industrial production of the dialkyl carbonate with remarkable economic and social benefit.

Owner:BEIJING JINJIAO BIOMASS CHEM IND

A biological fertilizer spreader

ActiveCN109757179BReduce wasteNo cloggingFertiliser distributersPressurised distribution of liquid fertiliserAgricultural scienceAgricultural engineering

The invention discloses a biological fertilizer spreader, comprising a spreader frame, a biological solid fertilizer loading box is fixedly connected to the middle position of the top of the spreader frame, and a biological solid fertilizer loading box is fixedly connected to the left side of the top of the spreader frame A liquid fertilizer loading tank, a support rack is fixedly connected to the bottom of the spreading rack, a fertilizer processing rack is arranged inside the biological solid fertilizer loading box, and a stirring motor is fixedly connected to the inner side of the fertilizer processing rack, and the fertilizer A stirring rack shaft is installed above the processing frame, driven gears are installed at both ends of the stirring rack shaft, and a connecting gear is meshed and connected below the driven gear. The invention relates to the technical field of biological fertilizers. The biological fertilizer spreader achieves the purpose of mixing, unloading and spreading of solid fertilizers. It can mix more stably without clogging the fertilization port and reduce the waste of fertilizer. The easily adjusted liquid fertilizer spreader can work Adjust the angle in the middle, suitable for spraying a variety of crops.

Owner:清原满族自治县宏运有机肥有限公司

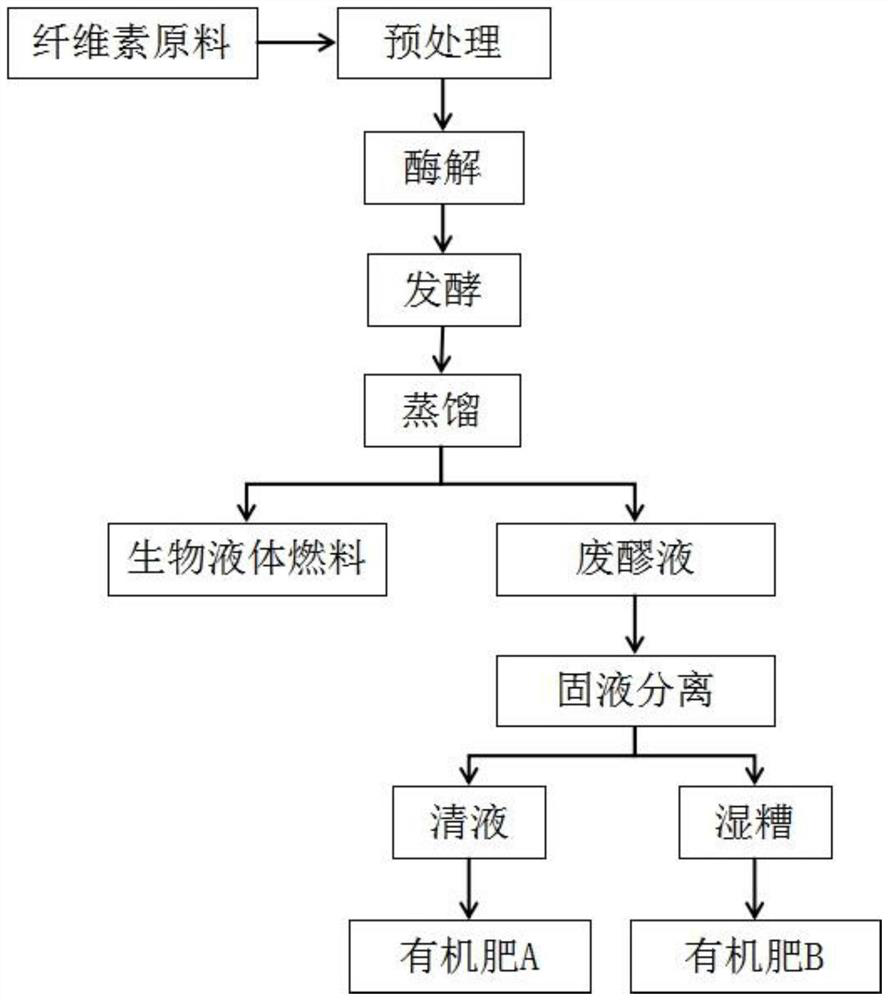

Method for preparing organic fertilizer and biological liquid fuel by utilizing lignocellulose

PendingCN114075579AImprove economyShort process routeBio-organic fraction processingBiofuelsEnzymatic hydrolysisSulfite salt

The invention relates to the field of production of organic fertilizers and biological liquid fuels, in particular to a method for preparing an organic fertilizer and a biological liquid fuel by utilizing lignocellulose. The method provided by the invention comprises the following steps: 1, mixing a lignocellulose raw material with sulfite and / or hydrosulfite, and heating for pretreatment; 2, mixing the pretreated material with cellulase, and carrying out enzymatic hydrolysis to produce sugar so as to obtain a sugar solution; 3, inoculating strains into the sugar liquid for biological liquid fuel fermentation to obtain fermented mature mash; 4, distilling the fermented mature mash to obtain biological liquid fuel and waste mash; and 5, carrying out solid-liquid separation on the waste mash to obtain a clear liquid and wet grains, and respectively obtaining an organic fertilizer A and an organic fertilizer B from the clear liquid and the wet grains. When the method provided by the invention is used for producing the organic fertilizer and the biological liquid fuel, the economical efficiency and the environmental protection property in the production process are improved.

Owner:GUOTOU BIO TECH INVESTMENT CO LTD

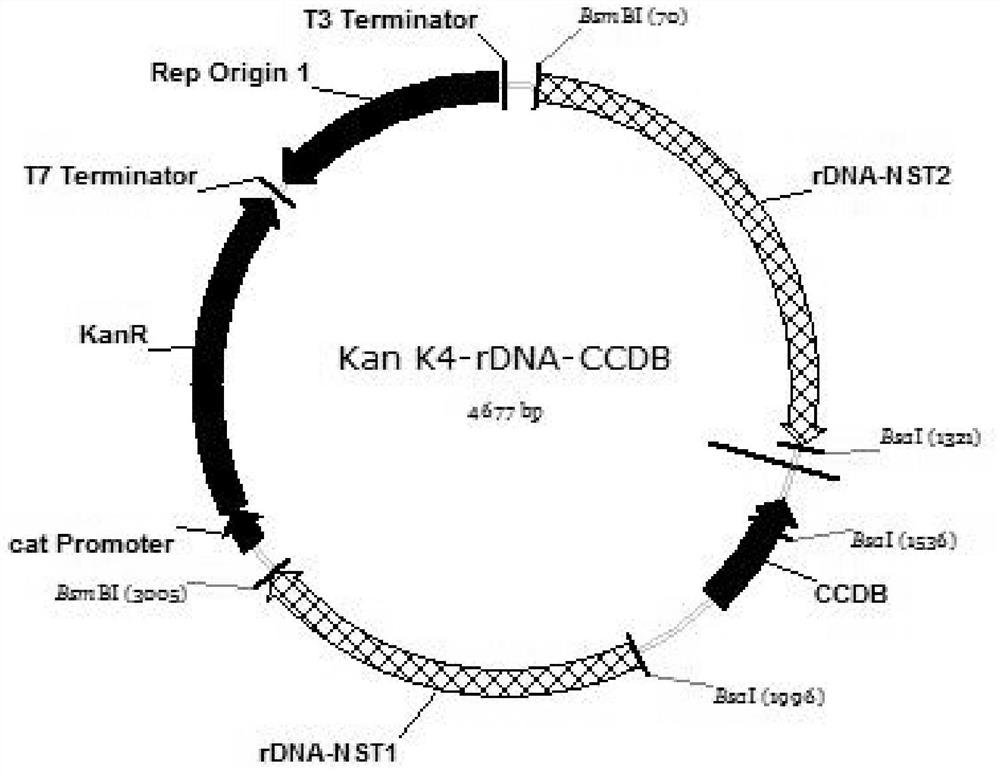

Recombinant Saccharomyces cerevisiae strain and its preparation method and application

ActiveCN109609540BImprove fermentation performanceMetabolically efficientFungiBiofuelsBiotechnologyGenetic engineering

The invention relates to the field of genetic engineering and metabolic engineering, discloses the field of genetic engineering and metabolic engineering, and specifically relates to a recombinant Saccharomyces cerevisiae strain and its preparation method and application. The recombinant Saccharomyces cerevisiae strain of the present invention comprises a gene expression cassette capable of expressing the genes of the following (1) to (3): (1) the araA gene from Pediococcus acidilactici, (2) the araA gene from Lactobacillus plantarum plantarum) araB gene, (3) araD gene from Lactobacillus plantarum. The recombinant Saccharomyces cerevisiae strain of the present invention has a metabolic pathway of exogenously integrated arabinose as a carbon source, and can utilize both glucose and arabinose in the process of preparing bioliquid fuel ethanol by fermenting lignocellulosic raw materials, and can realize lignocellulosic The sugar-alcohol conversion rate of 93.2% of the vegetarian raw material, and the fermentation performance of the bacterial strain are good, the ethanol production rate per ton of raw material is improved, the raw material utilization rate is improved, and the method is suitable for large-scale production of cellulosic ethanol.

Owner:JILIN COFCO BIOCHEM +2

Bio liquid fuel

InactiveCN101338224BIncrease cetane numberGood explosion resistanceLiquid carbonaceous fuelsOil and greaseLiquid fuel

The present invention relates to the field of chemicals, in particular to a renewable bio-liquid fuel for industrial production and living heat. The bio-liquid fuel takes bio-grease as the raw material and has the following physicochemical characteristics: the appearance: a transparent brown liquid; the solidifying point: 0 DEG C; the flash point: 46 DEG C; the copper strip corrosion (50 DEG C, 3hours): 1a level; the gross calorific value (kj / g): 40; the kinematic viscosity (mm<2> / s): 8. The bio-liquid fuel provided by the present invention has the advantages of high hexadecane value, good explosion resistance, large power, high oxygen content, full combustion, low oil consumption, good lubrication of motion components for reduce the wear of components and an oil injector, high flash point for transportation and storage, low solidifying point, low-temperature and good activation, low sulfur content and environmental protection. The bio-liquid fuel provided by the present invention can make use of the discarded bio-fat acid as the raw material for production, thus solving the problem of environmental pollution and partially satisfying the energy demand of industrial production and living heat.

Owner:SHANGHAI SHENXU SPECIAL MACHINE FUEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com