Special gasification burner for biological liquid fuel and combustion method

A biological liquid and burner technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of low fuel burnout rate, complex burner structure, complex combustion steps, etc., to avoid nitrogen contact and improve The effect of one-time burnout rate and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with embodiment:

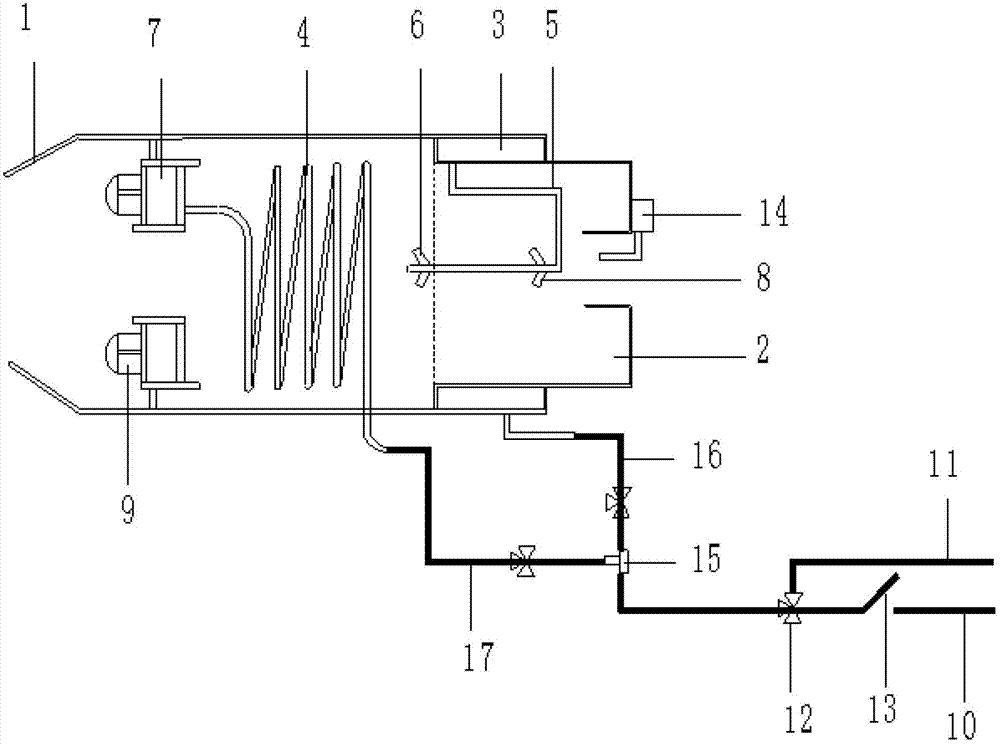

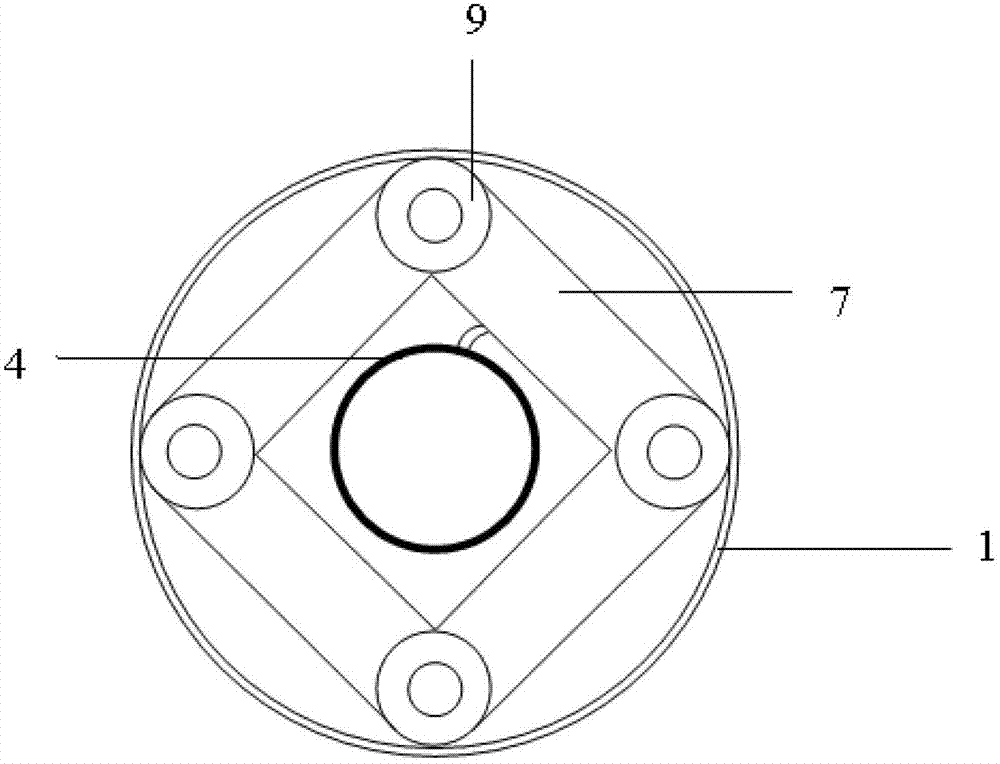

[0037] In this example, if figure 1 As shown, a special gasification burner for biological liquid fuel, the burner body is composed of a flame cover 1, a gasification chamber 3 and a combustion chamber 2, the gasification chamber 3 and the combustion chamber 2 are arranged in the flame cover 1, and the combustion chamber 2 Located at the rear end of the flame cover 1, the combustion chamber 2 is circular, and its rear end is connected to the pulse ignition device 14. The gasification chamber 3 is nested outside the combustion chamber 2, and the combustion chamber 2 is provided with an auxiliary gasification pipe 5, and the auxiliary gas One end of the gasification pipe 5 communicates with the gasification chamber 3 , and the other end is connected with the auxiliary nozzle 6 . The main gasification pipe 4 is located at the front end of the gasification chamber 3 and is connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com