Method and device for producing synthetic gas and method and device for synthesizing liquid fuel

A technology for synthesizing gas and liquid fuels, which is applied in the production of hydrogen/synthesis gas, biofuel, pyroligneous acid, etc., to achieve the effect of easy collection/transportation and simple treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

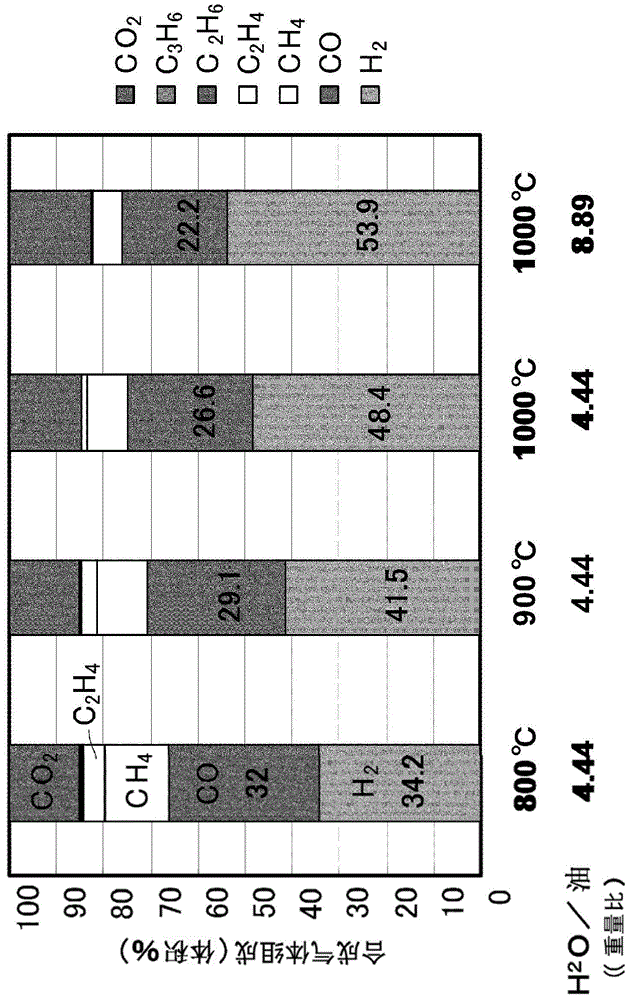

[0047] As a test device, a flow-through reactor in which reaction tubes made of SUS with an inner diameter of 54 mm and a length of 900 mm were installed vertically and electrically heated uniformly from the outer periphery was used. The above-mentioned space in the reaction tube with an inner diameter of 54 mm and a length of 900 mm is a gasification space. On the upstream side (below the gasification space), an electric furnace heating steam generating device is installed, and steam is supplied from the bottom of the reaction tube. The sample was fed through an insertion tube with an inner diameter of 5 mm using a microdoser in an upward flow of water vapor. A filter for collecting soot in the synthesis gas released from the reaction tube, a condenser for cooling the generated gas, and a drain bin are installed on the downstream side (above the gasification space) after the reaction.

[0048] The vaporization space is heated up to a specified temperature, and nitrogen and a...

Embodiment 2

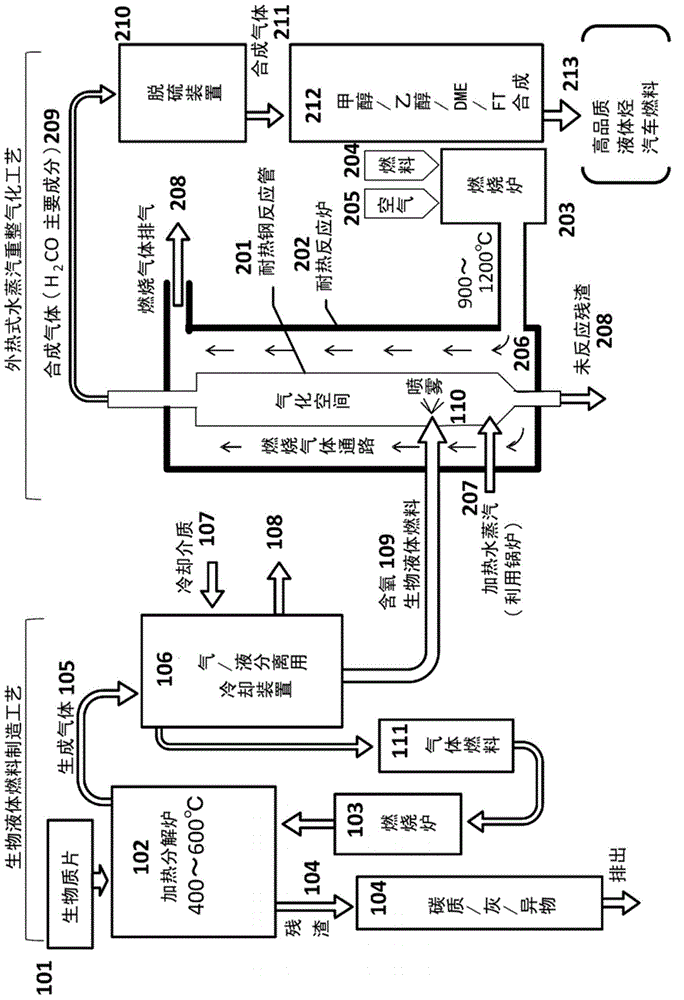

[0070] figure 2 It is an explanatory drawing which shows the manufacturing method and manufacturing apparatus of the synthetic gas of the example based on this invention.

[0071] In the figure, biomass chips 101 are heated to 400-600° C. in a thermal decomposition furnace 102 with hot gas from a combustion furnace 103, and the solid residue (carbonaceous / ash / foreign matter) 104 generated at this time is removed from the combustion furnace. Bottom discharge. The generated gas 105 taken from the upper part of the pyrolysis furnace 102 is separated into gaseous fuel 111 and biological liquid fuel 109 in the gas / liquid separation and cooling device 106. 107 and 108 are the inlet and outlet of the cooling medium, respectively.

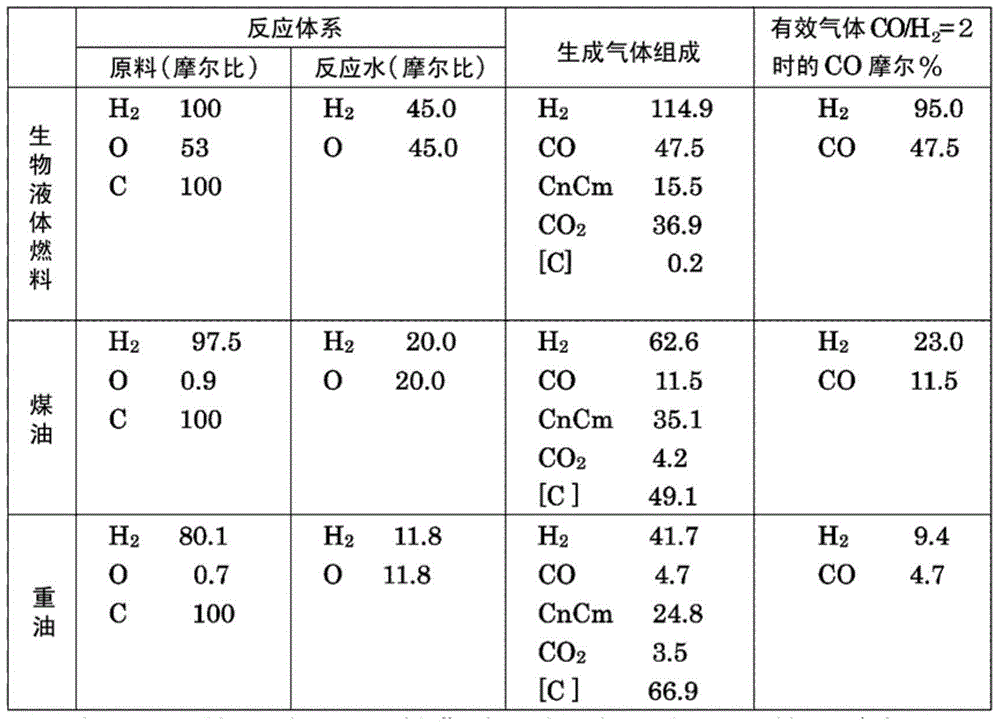

[0072] In this state, bio-liquid fuel 109 is generally an oxygen-containing hydrocarbon structure. The bioliquid fuel is directed into a refractory reactor furnace 202 . In the steam reforming gasification process of the present invention, the oxygen-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com