Method for catalyzing liquefaction of plant raw material by supercutical fluid

A supercritical fluid and plant raw material technology, which is applied in the field of supercritical fluid catalytic liquefaction of plant raw materials to obtain high-quality biomass oil, can solve the problems of unfavorable industrial production and low liquefaction rate of plant raw materials, and achieve easy separation, increase liquefaction rate, The effect of not corroding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

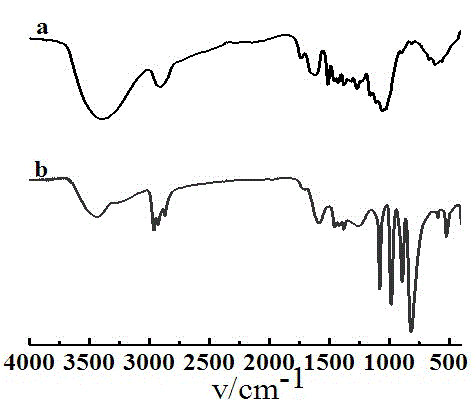

Image

Examples

Embodiment 1

[0018] The specific steps of a method for supercritical fluid catalyzed liquefaction of plant material are:

[0019] (1) Weigh 150 g of absolute ethanol and 1 g of fir sawdust into the autoclave, and add 0.5 g of phosphotungstic acid catalyst.

[0020] (2) The reactor was heated to 260 °C, the reaction time was 30 min, and the liquefaction rate was 95.35%.

Embodiment 2

[0022] The specific steps of a method for supercritical fluid catalyzed liquefaction of plant material are:

[0023] (1) Weigh 120 g of methanol and 1 g of corn stalks into the autoclave, and add 0.5 g of phosphomolybdic acid catalyst.

[0024] (2) The reactor was heated to 280 °C, the reaction time was 10 min, and the liquefaction rate was 90.34%.

Embodiment 3

[0026] The specific steps of a method for supercritical fluid catalyzed liquefaction of plant material are:

[0027] (1) Weigh 120 g of isopropanol and 1 g of flax into the autoclave, and add 0.4 g of zirconium phosphate catalyst.

[0028] (2) The reactor was heated to 250 °C, the reaction time was 30 min, and the liquefaction rate was 91.53%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com