A kind of environment-friendly biological liquid fuel and preparation method thereof

A biological liquid and environment-friendly technology, applied in liquid carbon-containing fuel, fuel, petroleum industry, etc., can solve the problems of low conversion rate and poor environmental protection, and achieve the effect of improved conversion rate, good environmental protection and good carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

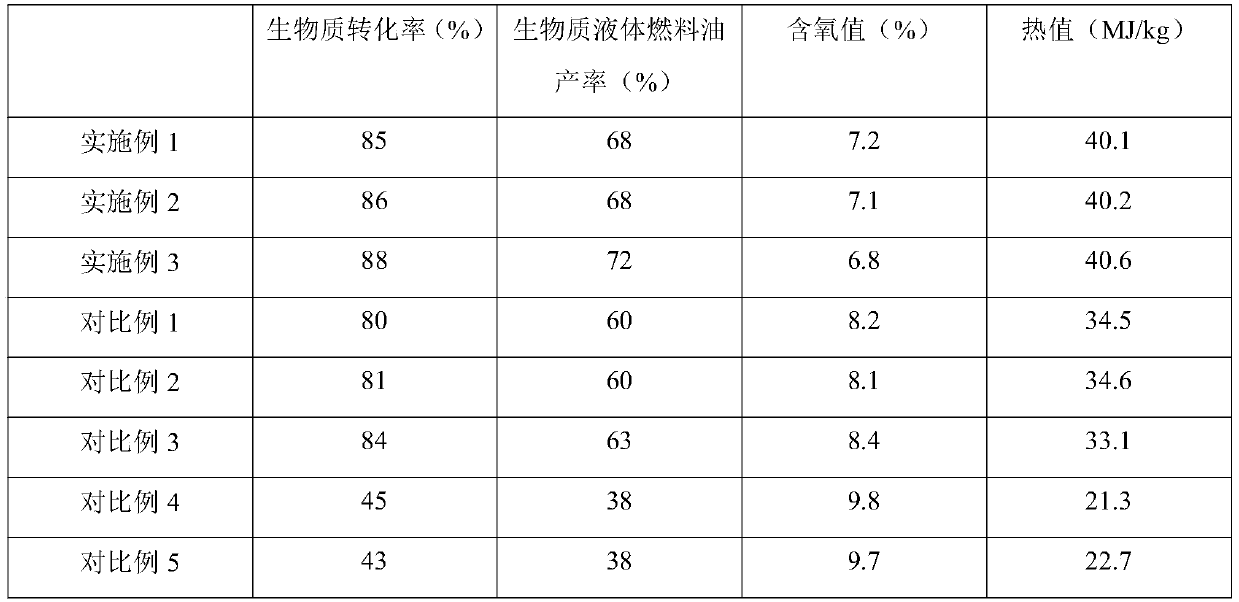

Examples

Embodiment 1

[0028] A preparation method of environment-friendly biological liquid fuel, the specific steps are as follows:

[0029] (1) Biomass pretreatment: soak cottonseed hulls, bagasse, walnut shells and chestnut shells in an alkaline solution for microwave treatment, carrageen and Ulva heat treatment, and combine the two parts to obtain pretreated biomass;

[0030] (2) Put the pretreated biomass and tetralin into the first cracking reactor according to the mass ratio of 1:0.08, heat to 400° C. to carry out the cracking reaction, and generate the first solid part and the first gas part;

[0031] (3) Put the first solid part, animal oil and anthracene into the second cracking reactor according to the mass ratio of 1:0.2:0.08, heat to 900°C for cracking reaction, and obtain the solid-liquid mixture and the second gas part, separate A solid-liquid mixture yields a liquid fraction;

[0032] (4) The first gas part obtained in step (2) and the second gas part obtained in step (3) are combi...

Embodiment 2

[0041] A preparation method of environment-friendly biological liquid fuel, the specific steps are as follows:

[0042] (1) Biomass pretreatment: soak cottonseed hulls, bagasse, walnut shells and chestnut shells in an alkaline solution for microwave treatment, carrageen and Ulva heat treatment, and combine the two parts to obtain pretreated biomass;

[0043] (2) Put the pretreated biomass and tetralin into the first cracking reactor according to the mass ratio of 1:0.1, and heat to 500°C to carry out the cracking reaction to generate the first solid part and the first gas part;

[0044] (3) Put the first solid part, animal oil and anthracene into the second cracking reactor according to the mass ratio of 1:0.3:0.1, heat to 1000°C for cracking reaction, and obtain the solid-liquid mixture and the second gas part, separate A solid-liquid mixture yields a liquid fraction;

[0045](4) The first gas part obtained in step (2) and the second gas part obtained in step (3) are combine...

Embodiment 3

[0054] A preparation method of environment-friendly biological liquid fuel, the specific steps are as follows:

[0055] (1) Biomass pretreatment: soak cottonseed hulls, bagasse, walnut shells and chestnut shells in an alkaline solution for microwave treatment, carrageen and Ulva heat treatment, and combine the two parts to obtain pretreated biomass;

[0056] (2) Put the pretreated biomass and tetralin into the first cracking reactor according to the mass ratio of 1:0.09, heat to 450° C. to carry out the cracking reaction, and generate the first solid part and the first gas part;

[0057] (3) Put the first solid part, animal oil and anthracene into the second cracking reactor according to the mass ratio of 1:0.25:0.09, heat to 950°C for cracking reaction, and obtain the solid-liquid mixture and the second gas part, separate A solid-liquid mixture yields a liquid fraction;

[0058] (4) The first gas part obtained in step (2) and the second gas part obtained in step (3) are comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com