Method for preparing bio oil through delignification pretreatment and liquefaction

A delignification and pretreatment technology, applied in the field of delignification pretreatment liquefaction to prepare bio-oil, can solve the problems of harsh reaction conditions, short heating rate, short residence time, rapid cooling, wide product distribution, etc., and achieve biomass conversion rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

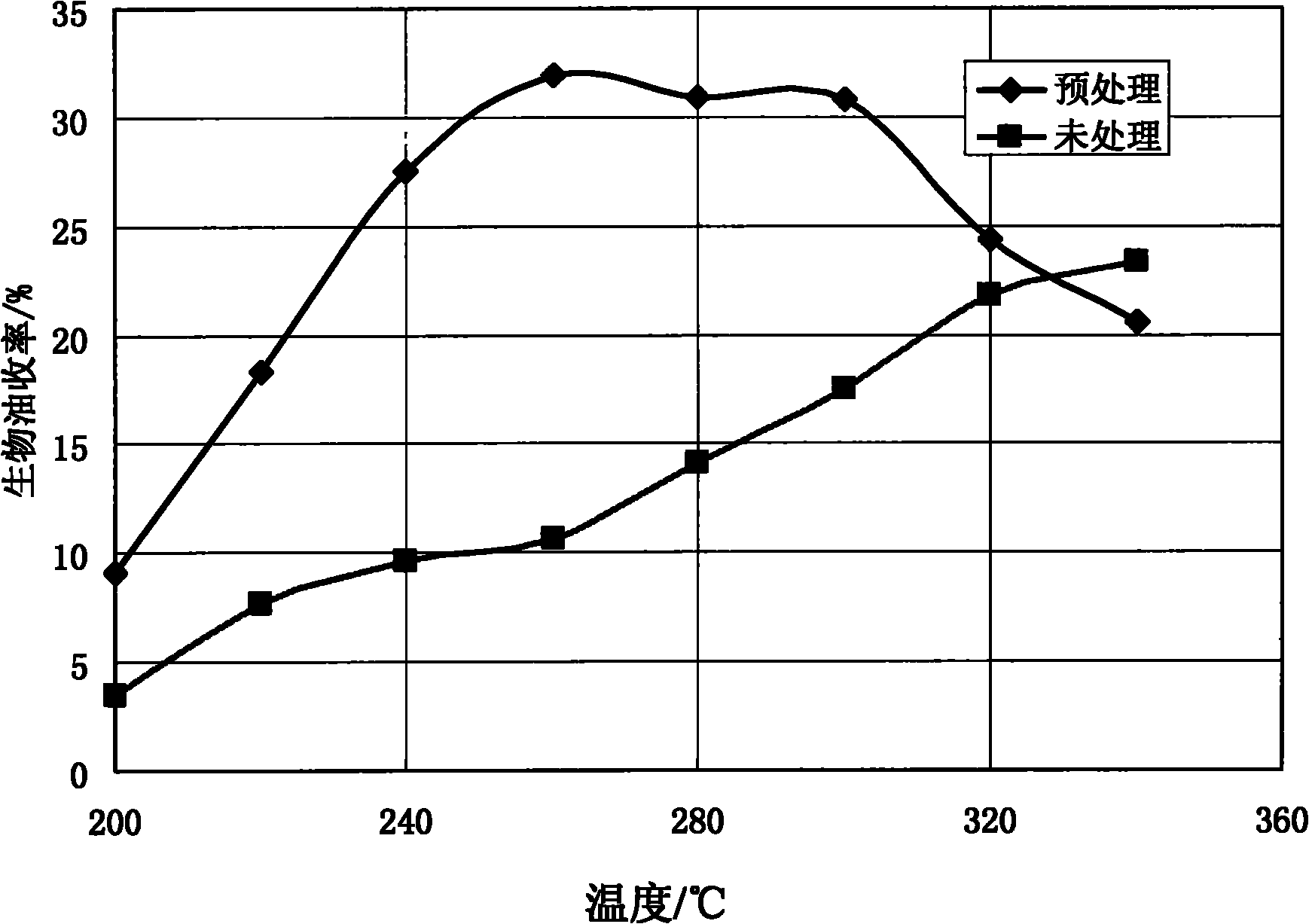

[0034] Liquefaction of corn stover without adding catalysts by delignification pretreatment

[0035] 1. Delignification pretreatment

[0036] Dry the corn stalks to a moisture content of 8%, and crush them to a fineness of 40 meshes. Add 100 g of crushed corn stalks to 200 g of water, chlorine gas is generated by adding 15 g of sodium hypochlorite and 15 mL of acetic acid, adjust the pH to 2, heat to 75 ° C and react for 80 minutes, and the lignin content of pretreated corn stalks is measured to be 29%. Accounting for 80% of the lignin content of untreated corn stalks (the lignin content of untreated corn stalks is 36%), the treated corn stalks are washed with water to remove the remaining sodium chlorite and acetic acid, dried to remove water.

[0037] 2. High pressure liquefaction

[0038] Add 10 g of corn stalks obtained in step 1 and 100 g of ethanol into a batch-type high-temperature and high-pressure reactor (Dalian Automatic Control Equipment Factory, GCF reactor, vol...

Embodiment 2

[0043] Liquefaction of delignified pretreated corn stalks with addition of catalysts

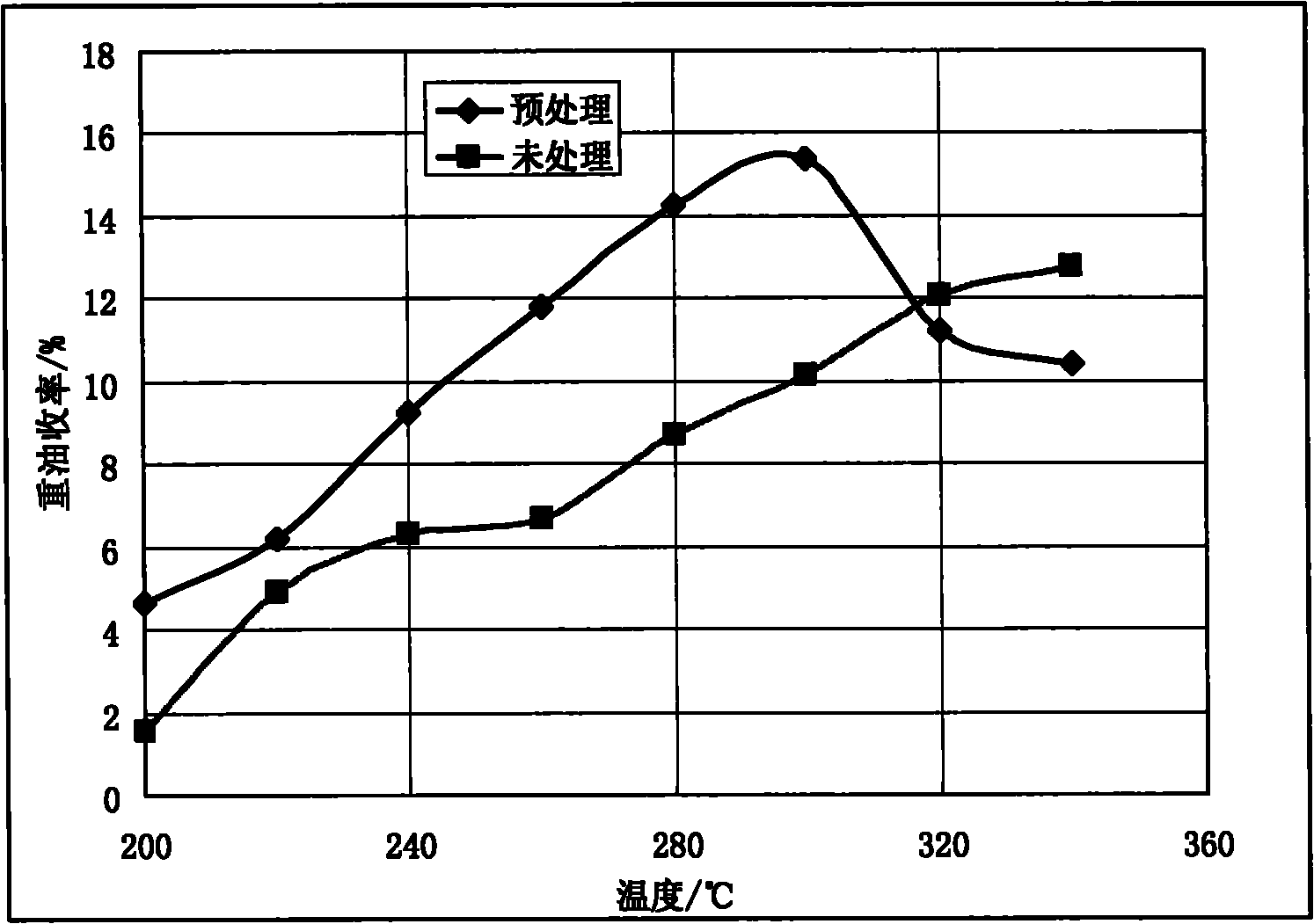

[0044] Get 10g embodiment 1 through delignification pretreated corn stalks, 100g ethanol and 1g sodium carbonate catalyst and join in the batch type high-temperature high-pressure reactor identical with embodiment 1, carry out by the same condition as in embodiment 1 Reaction, separation process is with the process in embodiment 1. Table 2 shows the change data of bio-oil yield with temperature after delignification pretreatment of corn stalks under the action of ethanol and potassium carbonate. The product yield is calculated based on the mass of the obtained product divided by the amount of raw material added to the reactor after removing the ash.

[0045] Table 2 shows that the yield of light oil increases with the increase of temperature, reaches the maximum value of 19.52% at the temperature of 280°C, and then the yield of light oil begins to decrease. The total bio-oil yield also rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com