Water-soluble copolyamide and preparation method thereof

A copolyamide, water-soluble technology, applied in the field of polymer material synthesis, to achieve the effect of improving water solubility, high environmental protection characteristics, and increasing biomass conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

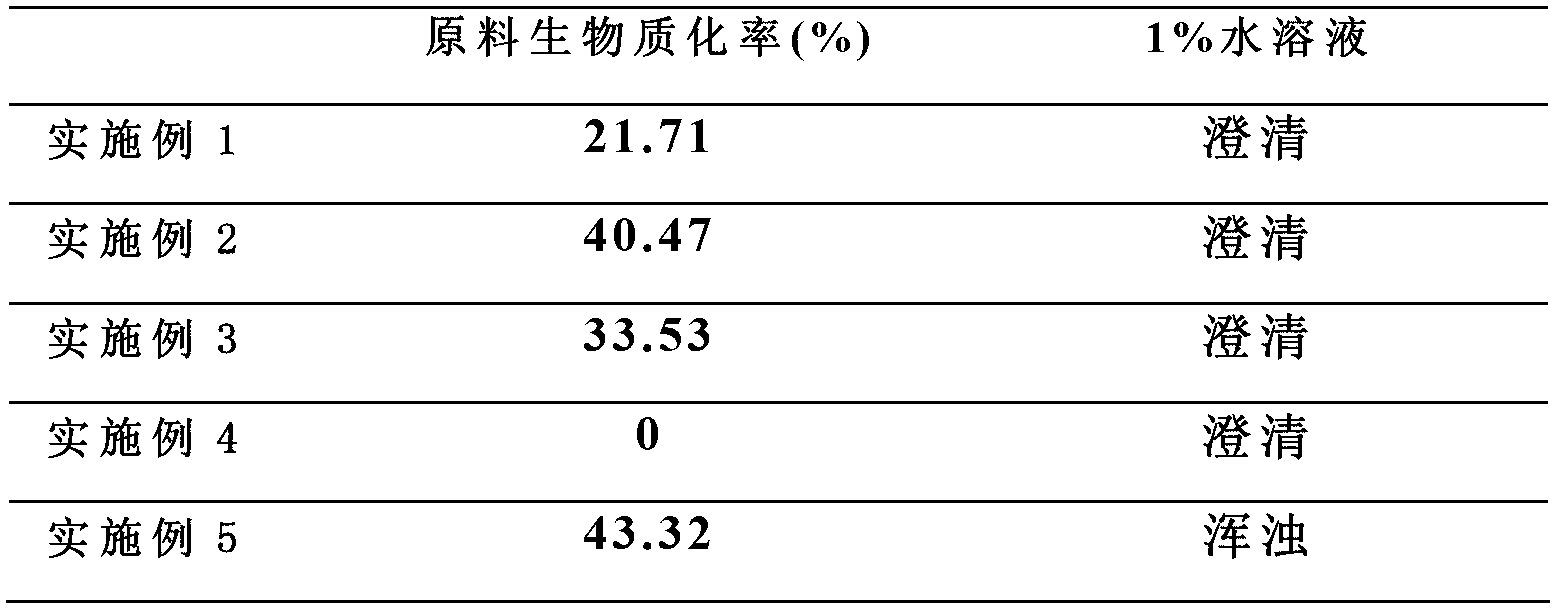

Embodiment 1

[0024] The preparation of embodiment 1 water-soluble copolyamide

[0025] Concretely prepare according to the following steps:

[0026] The reaction raw materials are fed according to the following molar ratio: 25% adipic acid, 25% furandicarboxylic acid, 50% polyether diamine (x=2), add a small amount of water as an initiator, and heat up to 140~160°C in an inert atmosphere. After keeping for 1-2 hours, the temperature rises to 180-220°C, and after keeping for 1-2 hours, the temperature rises to 230-250°C. Inert gas, water-soluble copolyamide can be obtained after the melt is cooled. The intrinsic viscosity of the product measured at 30°C with sulfuric acid as a solvent is 0.46;

Embodiment 2

[0027] The preparation of embodiment 2 water-soluble copolyamides

[0028] Concretely prepare according to the following steps:

[0029] The reaction raw materials are fed according to the following molar ratio: 25% adipic acid, 12.5% sebacic acid, 12.5% furandicarboxylic acid, 37.5% polyether diamine (x=2), 12.5% decane diamine, add a small amount of water as an initiator , raise the temperature to 140~160°C in an inert atmosphere, keep it for 1~2 hours, then raise it to 180~220°C, keep it for another 1~2 hours, then raise it to 230~250°C, keep it for 0.5~1 hour Then start to depressurize, fill in inert gas after 0.5~1 hour, and get the water-soluble copolyamide product after the melt is cooled. The intrinsic viscosity of the product measured at 30°C with sulfuric acid as a solvent is 0.42;

Embodiment 3

[0030] The preparation of embodiment 3 water-soluble copolyamides

[0031] Concretely prepare according to the following steps:

[0032] The reaction raw materials are fed according to the following molar ratio: 30% adipic acid, 5% sebacic acid, 10% furandicarboxylic acid, 40% polyether diamine (x=2), 5% decanediamine, 10% undecyl lactam , add a small amount of water as an initiator, raise the temperature to 140~160°C in an inert atmosphere, keep it for 1~2 hours, then raise the temperature to 180~220°C, keep it for another 1~2 hours, then raise the temperature to 230~250°C After keeping it for 0.5~1 hour, start to reduce the pressure, fill it with inert gas after 0.5~1 hour, and get the water-soluble copolyamide product after the melt is cooled. The intrinsic viscosity of the product measured at 30°C with sulfuric acid as a solvent is 0.42;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com