Nano titanium dioxide-zinc oxide hybrid material and synthesis method thereof

A nano-titanium dioxide and hybrid material technology, applied in the field of daily chemical materials, can solve the problems of troublesome operation, long mixing process, unable to reflect the hybrid structure, etc., to achieve performance, avoid performance unevenness, and enhance UV shielding performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

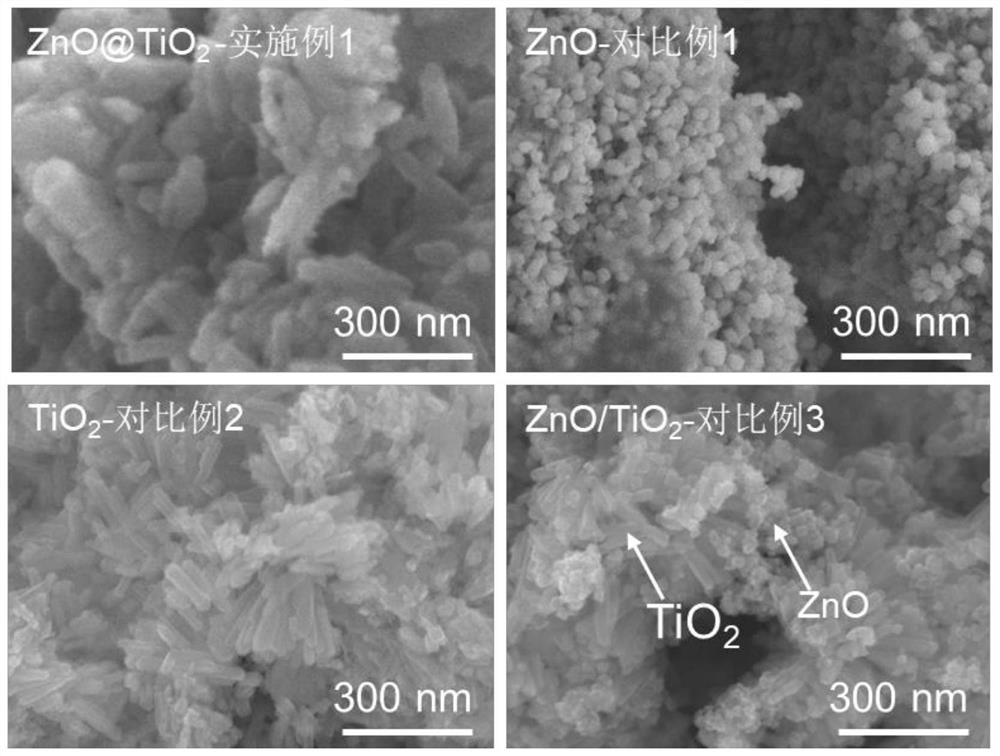

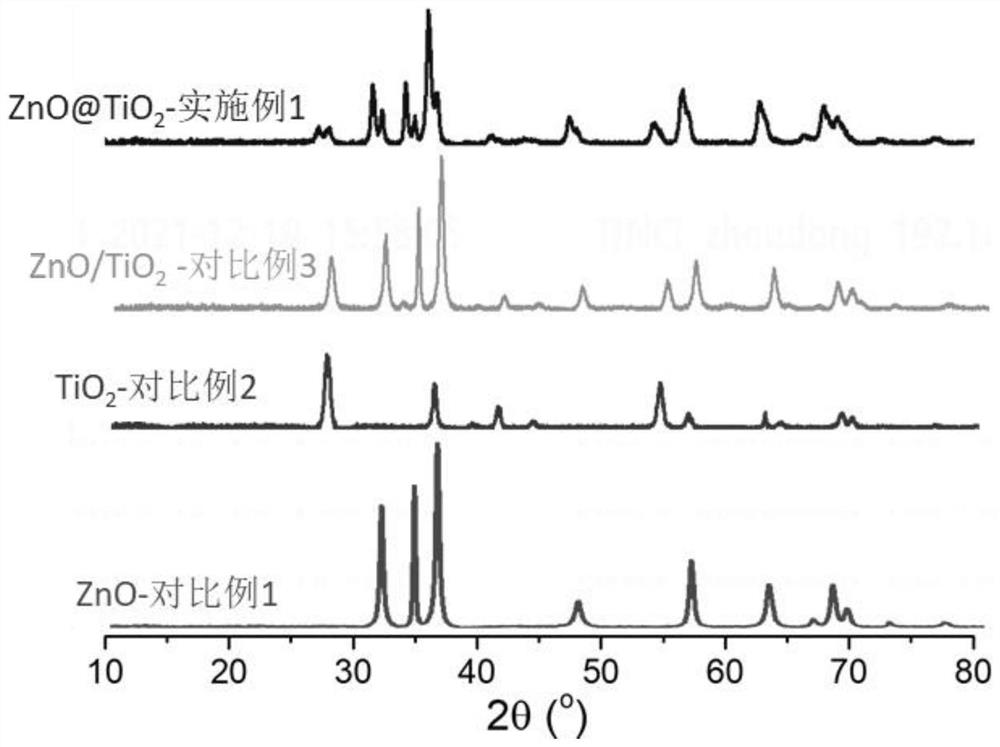

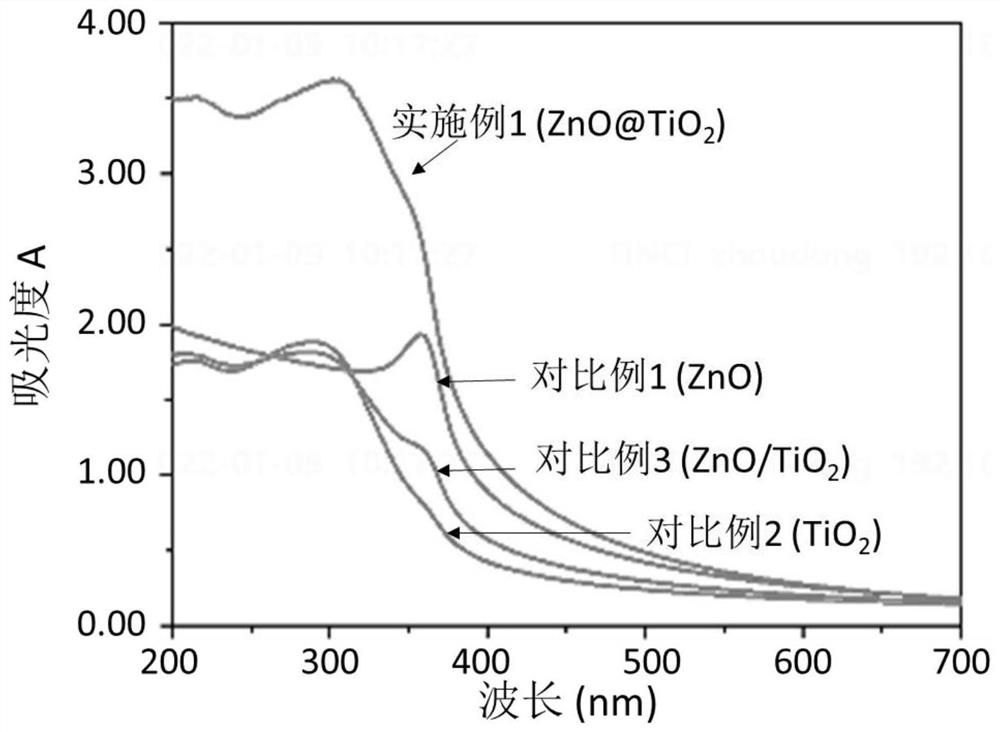

Embodiment 1

[0034] A method for synthesizing a nano-titanium dioxide-zinc oxide hybrid material of the present embodiment includes the following synthesizing steps:

[0035](1) slowly drip 5mL titanium tetrachloride into 100mL deionized water while stirring, control temperature to be 30 ℃, transfer the titanium tetrachloride aqueous solution to the hydrothermal reactor after the dripping, and stir the reaction at 180 ℃ After 2 hours, the obtained solution was filtered and washed, the wet filter cake was redispersed in 100 mL of deionized water, and the pH of the solution was adjusted to 5 with dilute hydrochloric acid to obtain hydroxyl-rich nano-TiO 2 Aqueous dispersion.

[0036] (2) The hydroxyl-rich nano-TiO obtained in step (1) 2 The aqueous dispersion was transferred to a 250 mL four-neck flask equipped with a stirring paddle and a thermometer, then 0.1 g of sodium polyacrylate as a complexing agent was added, heated to 60° C. and stirred for 30 min, and then 10.0 g of zinc acetate ...

Embodiment 2

[0041] A method for synthesizing a nano-titanium dioxide-zinc oxide hybrid material of the present embodiment selects linear polyacrylic acid as the coordinating agent, and includes the following synthesis steps:

[0042] (1) slowly drip 5mL titanium tetrachloride into 100mL deionized water while stirring, control temperature to be 30 ℃, transfer the titanium tetrachloride aqueous solution to the hydrothermal reactor after the dripping, and stir the reaction at 180 ℃ After 2 hours, the obtained solution was filtered and washed, the wet filter cake was redispersed in 100 mL of deionized water, and the pH of the solution was adjusted to 5 with dilute hydrochloric acid to obtain hydroxyl-rich nano-TiO 2 Aqueous dispersion.

[0043] (2) The hydroxyl-rich nano-TiO obtained in step (1) 2 The aqueous dispersion was transferred to a 250 mL four-necked flask equipped with a stirring paddle and a thermometer, then 0.1 g of polyacrylic acid as a coordinating agent was added, heated to 6...

Embodiment 3

[0048] A method for synthesizing a nano-titanium dioxide-zinc oxide hybrid material of the present embodiment selects linear polyvinylpyrrolidone as the coordinating agent, and includes the following synthesis steps:

[0049] (1) slowly drip 5mL titanium tetrachloride into 100mL deionized water while stirring, control temperature to be 30 ℃, transfer the titanium tetrachloride aqueous solution to the hydrothermal reactor after the dripping, and stir the reaction at 180 ℃ After 2 hours, the obtained solution was filtered and washed, the wet filter cake was redispersed in 100 mL of deionized water, and the pH of the solution was adjusted to 5 with dilute hydrochloric acid to obtain hydroxyl-rich nano-TiO 2 Aqueous dispersion.

[0050] (2) The hydroxyl-rich nano-TiO obtained in step (1) 2 The aqueous dispersion was transferred to a 250mL four-necked flask equipped with a stirring paddle and a thermometer, then 0.1g of the coordinating agent polyvinylpyrrolidone was added, heated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com