Polymer-pigment composite material

A polymer and soft polymer technology, applied in fibrous fillers, coatings, etc., can solve problems such as the adverse effects of corrosion resistance of metal coatings, achieve good water dispersion stability, improve anti-flocculation, and improve scrub resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

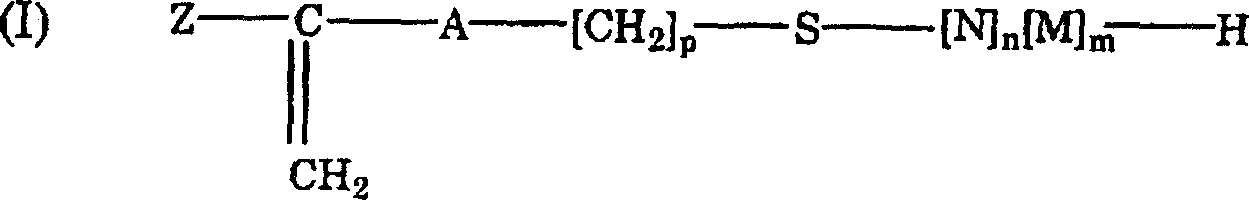

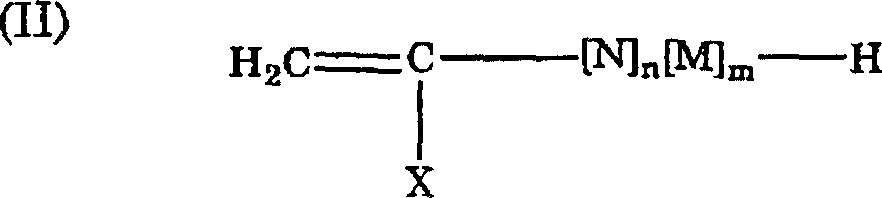

Method used

Image

Examples

Embodiment 1

[0108] Example 1 - Preparation of two-phase polymer particles by two-stage polymerization

[0109] The two-phase polymer particles of the present invention having a soft polymer phase and a hard polymer phase were prepared by two-stage polymerization as follows: an initial amount of deionized water was added to a flask and heated to 80° C. under a nitrogen atmosphere. Next, 10.0 grams of deionized water containing 10.0 grams of surfactant was added to the flask, followed by an initiator solution containing 4.8 grams of sodium persulfate in 50.0 grams of deionized water. Immediately after the addition of the initiator solution, the first monomer emulsion ME I was added to the flask at a rate of approximately 12.0 g / min while maintaining the temperature of the reaction mixture at 80°C. After the addition of the first monomer emulsion was complete, the contents of the flask were held at 80°C for 10 minutes. Next, a second monomer emulsion ME II was added to the flask at a rate...

Embodiment 2

[0112] Example 2 - Preparation of single-phase polymer particles for comparison

[0113]Single-phase polymer particles for comparison were prepared as follows: an initial amount of deionized water was added to a flask and heated to 80°C under a nitrogen atmosphere. Next, a soap solution was prepared and added to the flask, followed by the initiator solution. Immediately after the addition of the initiator solution, monomer emulsion (ME) was added to the flask at a rate of approximately 17.5 g / min while maintaining the temperature of the reaction mixture at 80°C. After the addition of the monomer emulsion was complete, the contents of the flask containing the dispersion were held at 80°C for 15 minutes and then allowed to cool to 15°C. Next, aqueous ammonia (28%) was added to raise the pH to 8.0-10.0. Filter the contents of the flask to remove any coagulum.

[0114] Example

Initial D.I.

water (g)

soap solution

Initiator solution

monomer em...

Embodiment 4

[0138] Example 4 - Coating Results

[0139] Paints containing composite particles of the invention were compared to comparative paints containing composite particles. The comparative paint used to determine tri-tin strength and scrub ratio was the paint without composite particles.

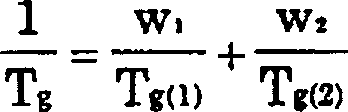

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com