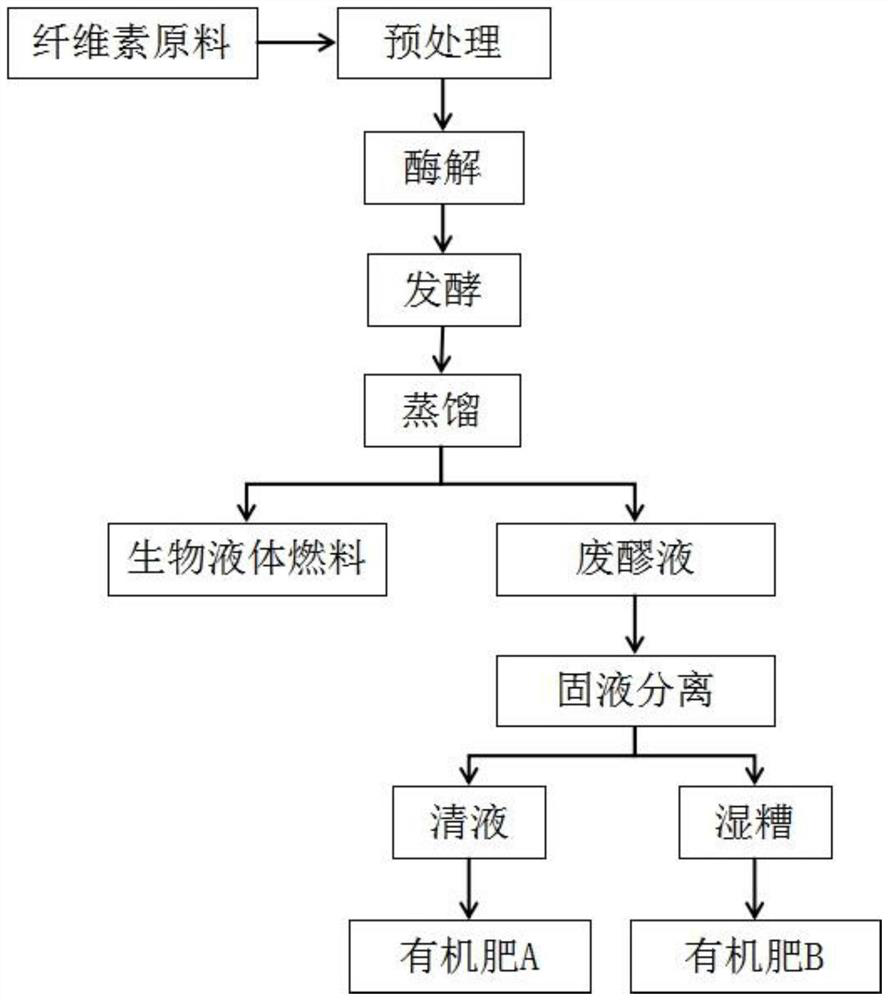

Method for preparing organic fertilizer and biological liquid fuel by utilizing lignocellulose

A technology of lignocellulose and biological liquid, which is applied in the direction of organic fertilizers, biofuels, liquid carbon-containing fuels, etc., can solve the problems of complex production process of cellulosic ethanol, large water consumption, and high cost, so as to improve equipment utilization efficiency and reduce Water consumption, energy consumption, and overall cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] The lignocellulosic raw material used in this example is corn stalks, and the sulfite used is sodium sulfite.

[0091] Step 1: In the pretreatment system, the concentration of corn stalks is 20% by weight, the concentration of sodium sulfite is 2% by weight, and the balance is water, mix well, heat and cook after sealing, heat up to 165°C, and maintain at this temperature for 90 minutes ;

[0092] Step 2: After cooking, water and cellulase are added to the material for enzymatic hydrolysis to produce sugar. Wherein, in the enzymatic hydrolysis sugar production system, the concentration of cellulase is 1% by weight, and the concentration of insoluble substrate is 10% by weight. pH is 5, enzymatic hydrolysis at 50°C for 72 hours;

[0093] Step 3: After the enzymatic hydrolysis, inoculate the C5 strain in the sugar solution with an inoculation amount of 3 g / L. Adjust the pH to 5.5, and ferment at 32°C for 72 hours;

[0094] Step 4: Distill the fermented mature mash, di...

Embodiment 2

[0103] The lignocellulosic raw material selected in this embodiment is corn stalks, and the selected sulfite is ammonium sulfite.

[0104] Step 1: In the pretreatment system, the concentration of corn stalks is 20% by weight, the concentration of ammonium sulfite is 2% by weight, fully mixed, sealed and heated to steam explosion, the temperature is raised to 185°C, the pressure is 1.12MPa, and maintained at this temperature 60 minutes;

[0105] Step 2: After steam explosion, water and cellulase are added to the material for enzymatic hydrolysis to produce sugar. Wherein, in the enzymatic hydrolysis sugar production system, the concentration of the enzyme preparation is 1.5% by weight, the concentration of the insoluble substrate is 10% by weight, the pH is 5, and the enzymolysis is carried out at 50°C for 72 hours;

[0106] Step 3: After the enzymatic hydrolysis, inoculate the C5 strain in the sugar solution with an inoculation amount of 3 g / L. Adjust the pH to 5.5 and ferme...

Embodiment 3

[0115] The lignocellulosic raw material selected in this embodiment is corn stalks, the selected sulfite is ammonium sulfite, and the selected alkali is sodium hydroxide.

[0116] Step 1: In the pretreatment system, the concentration of corn stalks is 20% by weight, the concentration of ammonium sulfite is 2% by weight, and the concentration of sodium hydroxide is 3% by weight. Among them, ammonium sulfite and sodium hydroxide are added at the same time, pretreated by cooking, fully mixed, heated and cooked after sealing, the temperature is raised to 185 ° C, and maintained at this temperature for 90 minutes;

[0117] Step 2: After cooking, water and cellulase preparation are added to the material for enzymatic hydrolysis to produce sugar. Wherein, in the enzymatic sugar production system, the concentration of the enzyme preparation is 0.5% by weight, the concentration of the insoluble substrate is 10% by weight, the pH is 5, and the enzyme is hydrolyzed at 50°C for 72 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com