A kind of preparation method of low-viscosity carbon deposition-reduced fuel oil

A fuel oil and low-viscosity technology, applied in fuels, fuel additives, liquid carbon-containing fuels, etc., can solve problems such as low operating efficiency of combustion furnaces or engine cylinders, increased coking and carbon deposits, poor atomization, etc., to achieve improved The effects of atomization dispersion performance, increased oxygen content, and strong ability to compete for nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

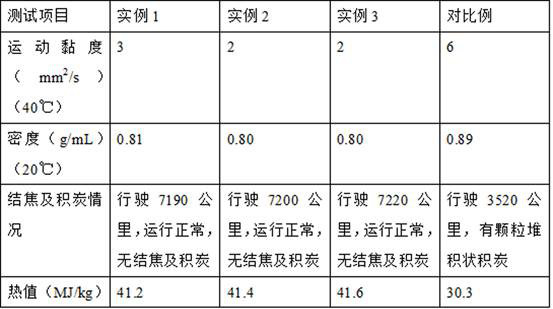

Examples

example 1

[0025] In parts by weight, 70 parts of biogas slurry, 20 parts of shell powder, 4 parts of chitosanase, 5 parts of Nile red, and 5 parts of chlorella were added to the plastic tank, and they were placed in a place with sufficient light and air circulation for cultivation. During the period, after the daily light was over, the culture liquid in the plastic tank was inspected with ultraviolet light. After the surface of the culture liquid in the plastic tank was found to be completely covered with red, the culture was terminated, and the surface chlorella was salvaged, and put into a high-speed centrifuge for dehydration. Rotate at 4000r / min, centrifuge for 12min, remove the supernatant to obtain the lower chlorella sediment, put the chlorella sediment into an oven, heat up to 80°C, and dry for 10 hours to obtain the dried chlorella sediment; Place the dried chlorella sediment in an ultrasonic breaker to break the wall, control the ultrasonic frequency to 40kHz, and the ultrasoni...

example 2

[0027] In parts by weight, 75 parts of biogas slurry, 22 parts of shell powder, 4 parts of chitosanase, 7 parts of Nile red, and 7 parts of chlorella were added to the plastic tank, and placed in a place with sufficient light and air circulation for cultivation. During the period, after the daily light was over, the culture liquid in the plastic tank was inspected with ultraviolet light. After the surface of the culture liquid in the plastic tank was found to be completely covered with red, the culture was terminated, and the surface chlorella was salvaged, and put into a high-speed centrifuge for dehydration. Rotate at 4100r / min, centrifuge for 14min, remove the supernatant to obtain the lower chlorella sediment, put the chlorella sediment into an oven, heat up to 85°C, and dry for 11 hours to obtain the dried chlorella sediment; Place the dried chlorella sediment in an ultrasonic breaker to break the wall, control the ultrasonic frequency to 42kHz, and the ultrasonic treatmen...

example 3

[0029] In parts by weight, add 80 parts of biogas slurry, 25 parts of shell powder, 5 parts of chitosanase, 10 parts of Nile red, and 10 parts of chlorella to the plastic tank, and place it in a place with sufficient light and air circulation for cultivation. During the period, after the daily light was over, the culture liquid in the plastic tank was inspected with ultraviolet light. After the surface of the culture liquid in the plastic tank was found to be completely covered with red, the culture was terminated, and the surface chlorella was salvaged, and put into a high-speed centrifuge for dehydration. Rotate at 4300r / min, centrifuge for 15 minutes, remove the supernatant to obtain the lower layer of chlorella sediment, put the chlorella sediment into an oven, heat up to 90°C, and dry for 12 hours to obtain the dried chlorella sediment; Place the dried chlorella sediment in an ultrasonic breaker to break the wall, control the ultrasonic frequency to 45kHz, and the ultrason...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com