Method for manufacturing bio-liquid fuel

A technology for biological liquids and manufacturing methods, which is applied to liquid carbon-containing fuels, fuels, chemical instruments and methods, etc., can solve the problems of oil separation, time-consuming and labor-intensive refining, etc., and achieve excellent results of the method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

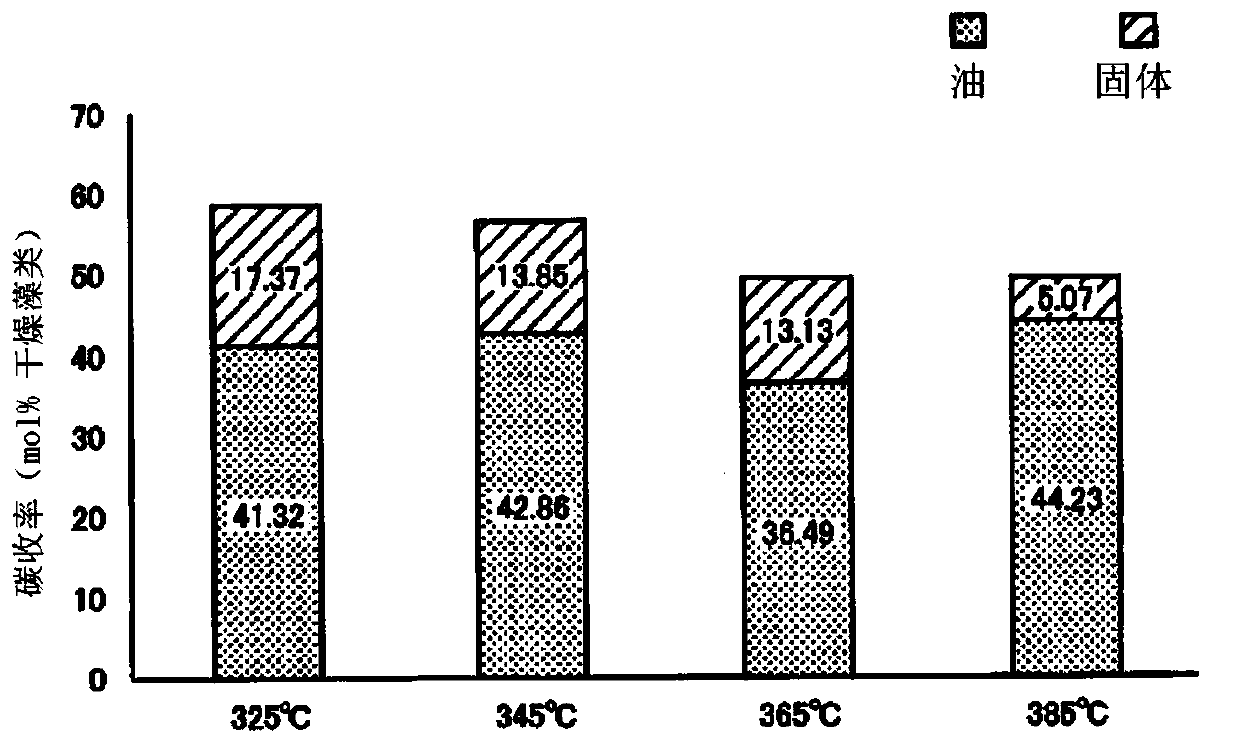

Examples

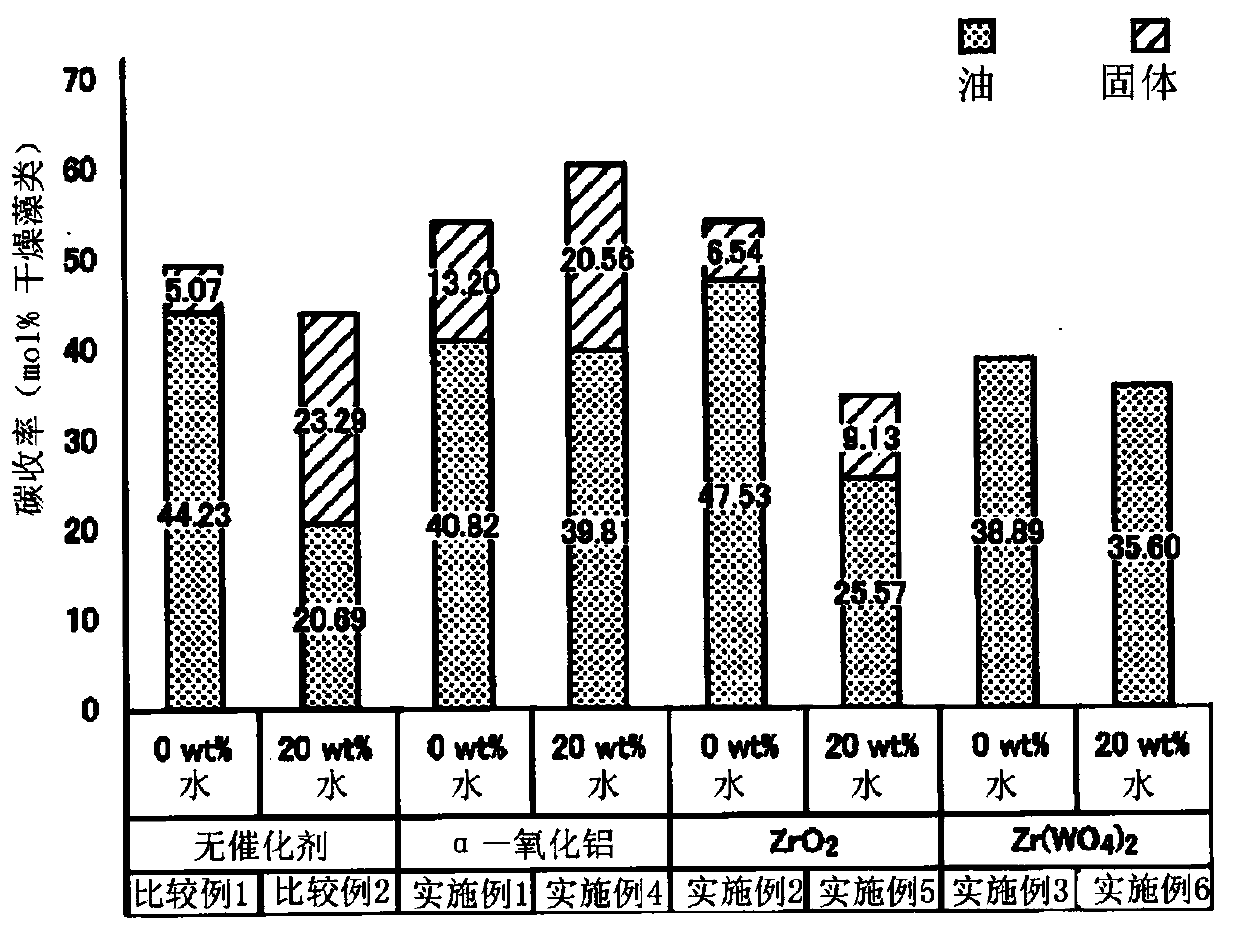

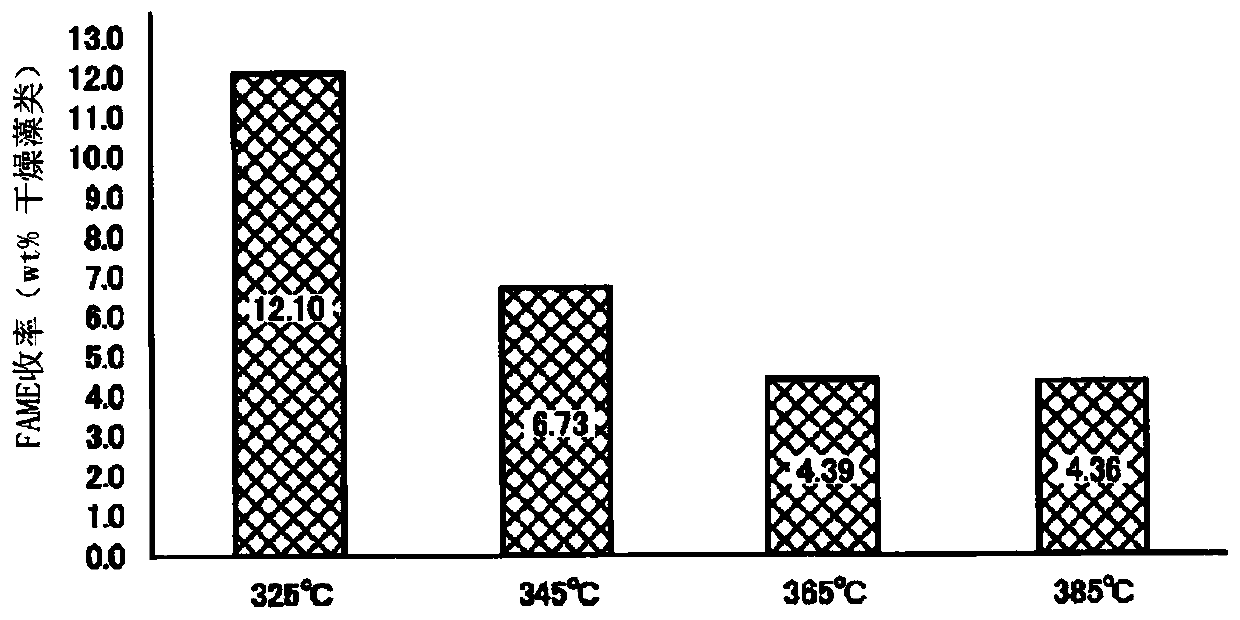

Embodiment 1

[0064] A stainless steel tube (SUS316, 1 / 2 inch in outer diameter, 2.1 mm in thickness, 15 cm in length) equipped with a high-pressure needle valve via a stainless steel tube (SUS316, 1 / 8 inch in outer diameter) at one end was used as a batch reaction vessel. About 0.56 g of chlorella vulgaris (C. vulgaris) powder (manufactured by Chlorella Industry Co., Ltd., average particle size: 76 μm), 4.0 g of anhydrous methanol, and 0.028 g of α-alumina as a catalyst were put into a reaction container.

[0065] The batch reaction container was immersed in a molten salt bath previously heated to 385° C., and after 60 minutes, the reaction container was lifted from the molten salt bath and rapidly cooled to room temperature with running water.

[0066] The generated gas was recovered using an air bag, and the volume was measured by the water displacement method.

[0067] The solid product was recovered by filtering the liquid product using filter paper.

[0068] The liquid product was ex...

Embodiment 2

[0071] It carried out similarly to Example 1 except having used zirconia as a catalyst.

[0072] show the result in figure 2 with Figure 4 .

Embodiment 3

[0074] As a catalyst, it carried out similarly to Example 1 except having used zirconium tungstate.

[0075] show the result in figure 2 with Figure 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com