Medical test tube cleaning equipment

A technology for cleaning equipment and test tubes, which is applied in the medical field and can solve problems such as single function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

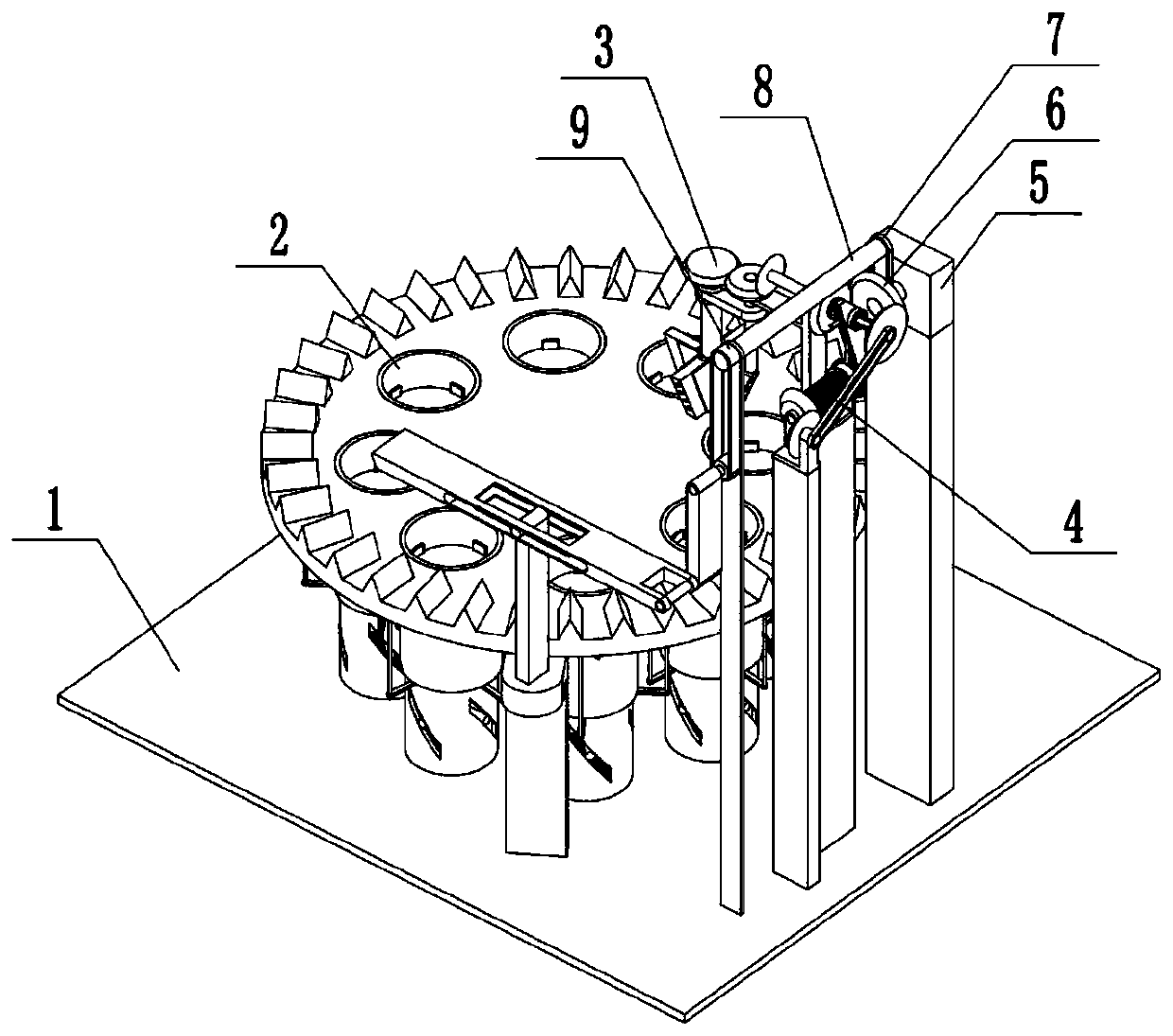

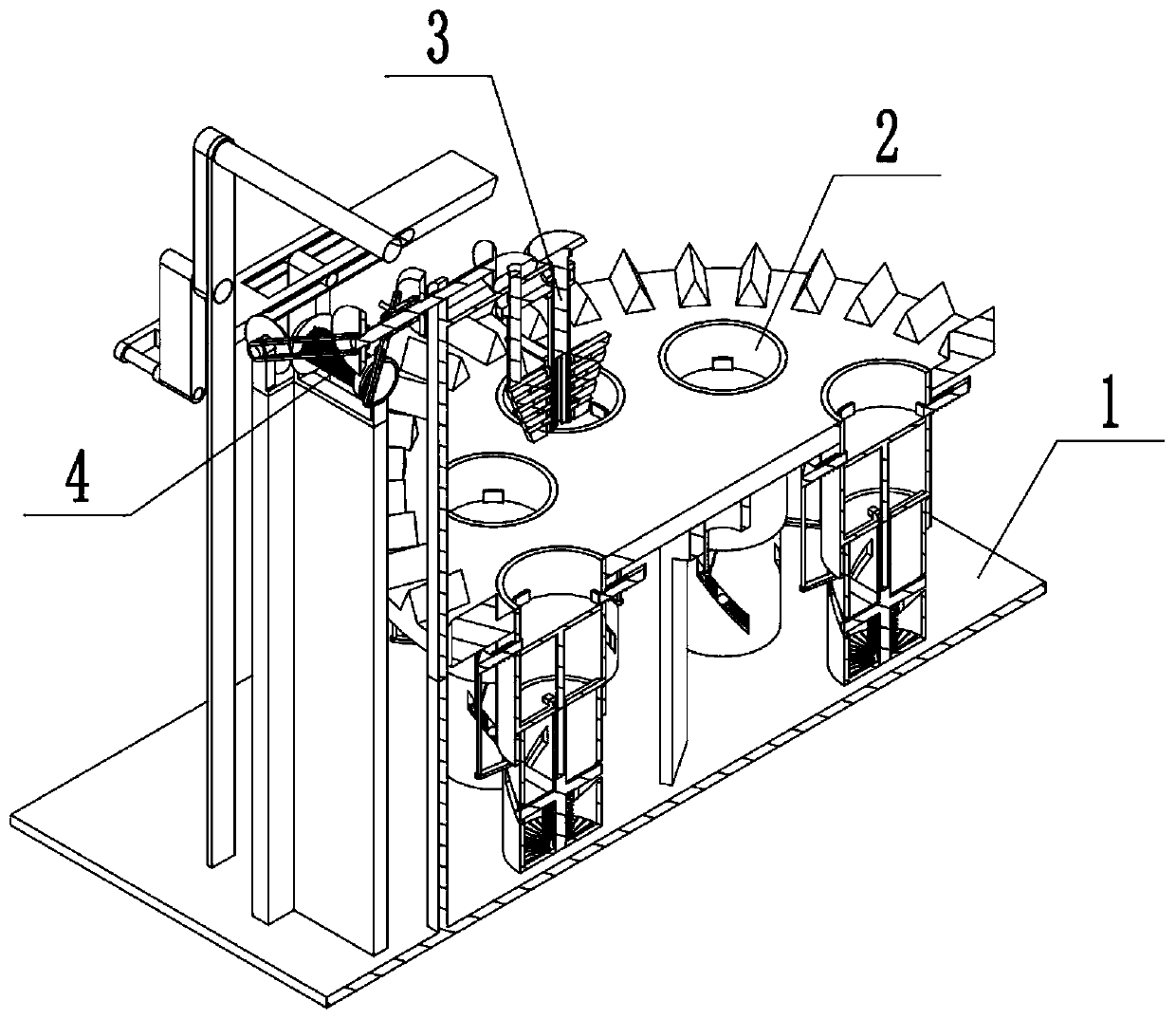

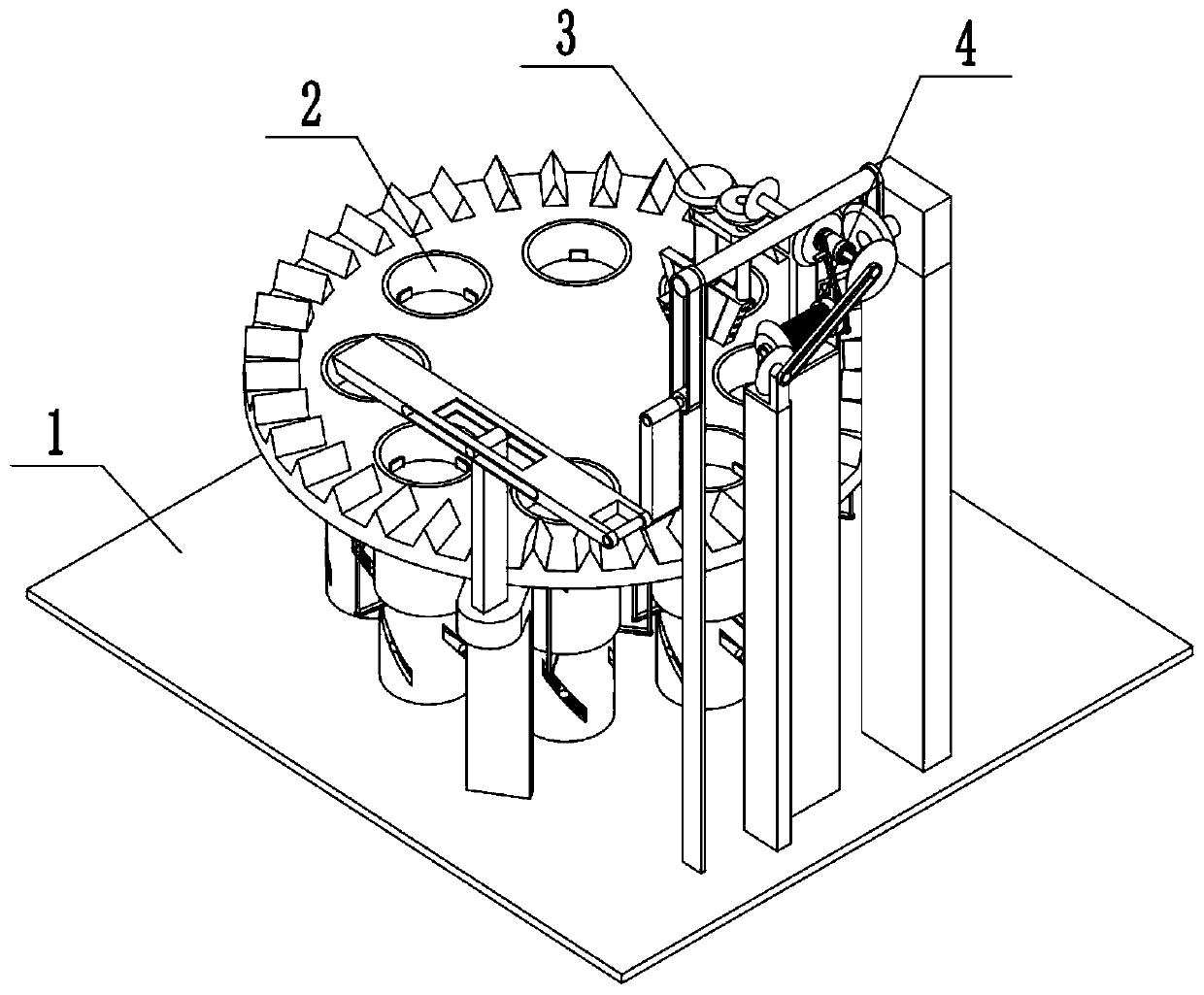

[0029] Combine below Figure 1-12Describe this embodiment, a medical test tube cleaning equipment, including a turntable assembly 1, a test tube fixing assembly 2, a cleaning brush assembly 3, a middle-end transmission assembly 4, an input motor 5, an input bevel gear 6, and an input belt 7 , middle end shaft 8, output belt 9, it is characterized in that: described input bevel gear 6 is fixedly connected with input motor 5, input motor 5 is connected with turret assembly 1, middle end shaft 8 is connected with input belt 7, output belt 9 are connected, the input belt 7 is connected with the input motor 5, the turntable assembly 1 is connected with the test tube fixing assembly 2, the cleaning brush assembly 3 is connected with the turntable assembly 1, the middle end transmission assembly 4 is connected with the rotary The frame assembly 1 is connected, the middle transmission assembly 4 is connected with the input bevel gear 6, and the middle transmission assembly 4 is connec...

specific Embodiment approach 2

[0031] Combine below Figure 1-12 Describe this embodiment, this embodiment will further explain the first embodiment, the turntable assembly 1 includes the bottom frame 1-1, the first bracket 1-2, the second bracket 1-3, the third bracket 1-4, and the fourth bracket 1 -5, bracket five 1-6, driving rotating column one 1-7, hinged rotating rod 1-8, hinged push rod one 1-9, middle end turntable 1-10, driving boss 1-11, bracket one 1- 2. Support three 1-4, support four 1-5, support five 1-6 are fixedly connected with the base frame 1-1, support two 1-3 is fixedly connected with support one 1-2, and drive rotating column one 1-7 is connected with Bracket four 1-5 are rotationally connected, hinged rotating rod 1-8 is fixedly connected with drive rotating column one 1-7, hinged rotating rod 1-8 is hingedly connected with hinged push rod one 1-9, hinged push rod one 1-9 is connected with Bracket 2 1-3 cooperates with the link, the middle end turntable 1-10 is rotatably connected wi...

specific Embodiment approach 3

[0033] Combine below Figure 1-12 This embodiment will be described. This embodiment will further explain the first embodiment. The test tube fixing assembly 2 includes an upper casing 2-1, a lower casing 2-2, a side wall chute 2-3, and an inner drive Slide rod 2-4, side wall bracket rod 2-5, upper fixed slide rod 2-6, slide rod push spring 2-7, inner end push spring 1 2-9, bearing slide rod 2-10, spherical chute 2-11, the lower casing 2-12, the spherical sliding rod 2-13, the spherical sliding rod push spring 2-14, the cross rod 2-15, the lower casing 2-2 is rotationally connected with the upper casing 2-1 , the side wall chute 2-3 is set on the lower side casing 2-2, the inner drive slide bar 2-4 is connected with the side wall chute 2-3, and the lower end sleeve 2-12 is connected with the inner end drive slide bar 2 -4 is fixedly connected, the inner end push spring 1 2-9 is socketed and connected with the lower sleeve 2-12, the lower sleeve 2-12 is slidingly connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com