Catelectrode atomization type preweld cleaning equipment for aluminum alloy welding wire

An aluminum alloy welding wire and cathode atomization technology, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve problems such as joint use, incomplete treatment of aluminum alloy welding wire, and difficult welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

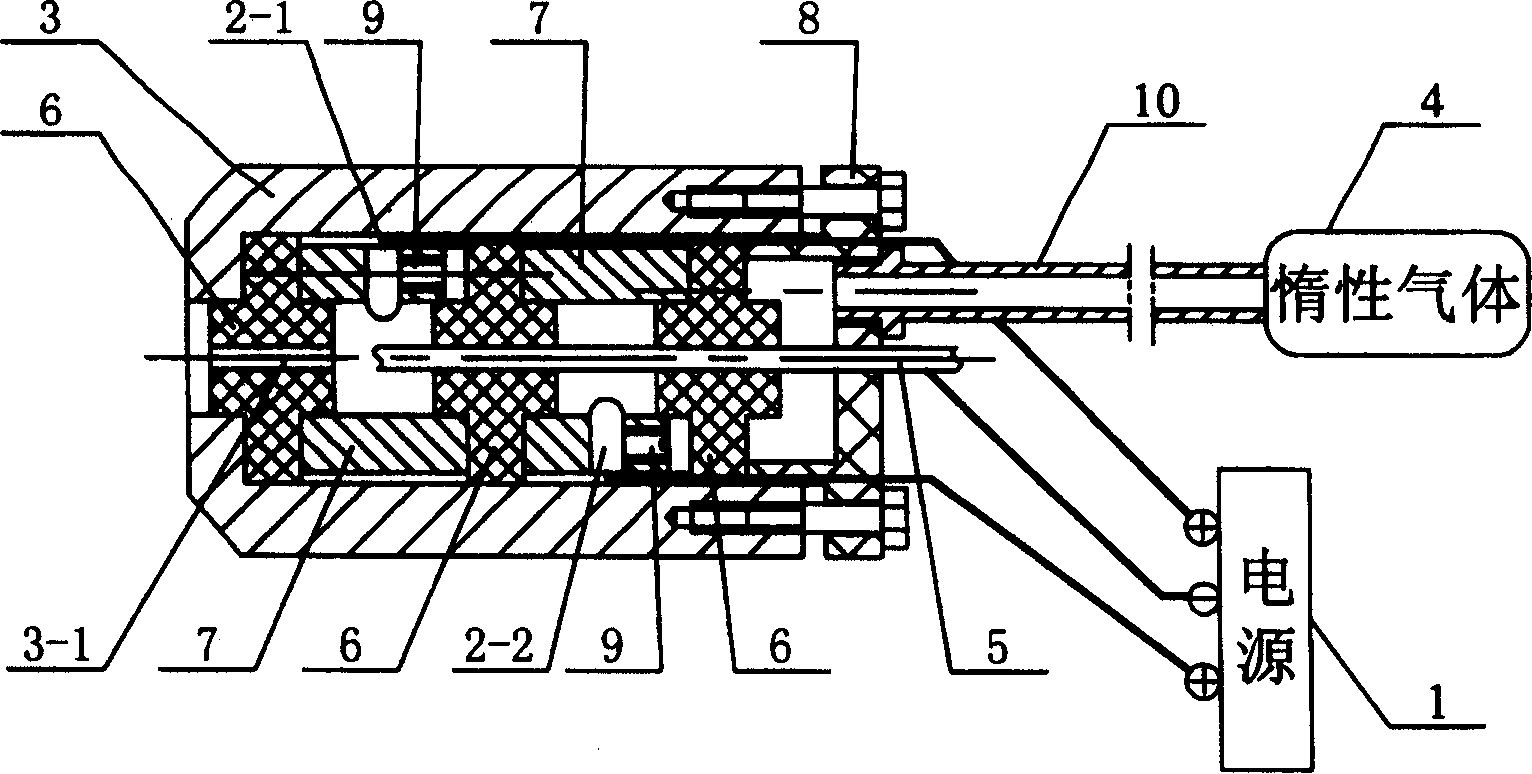

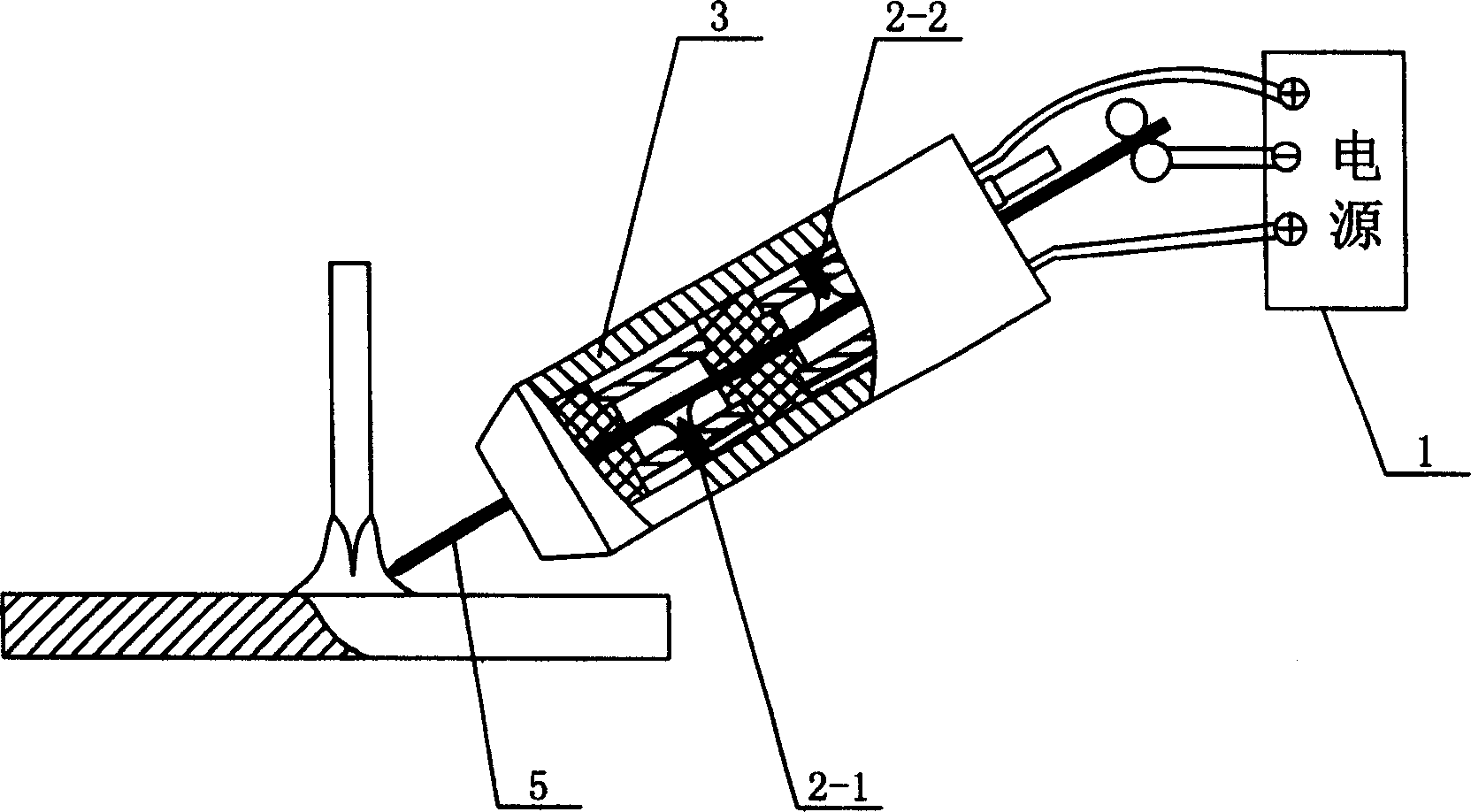

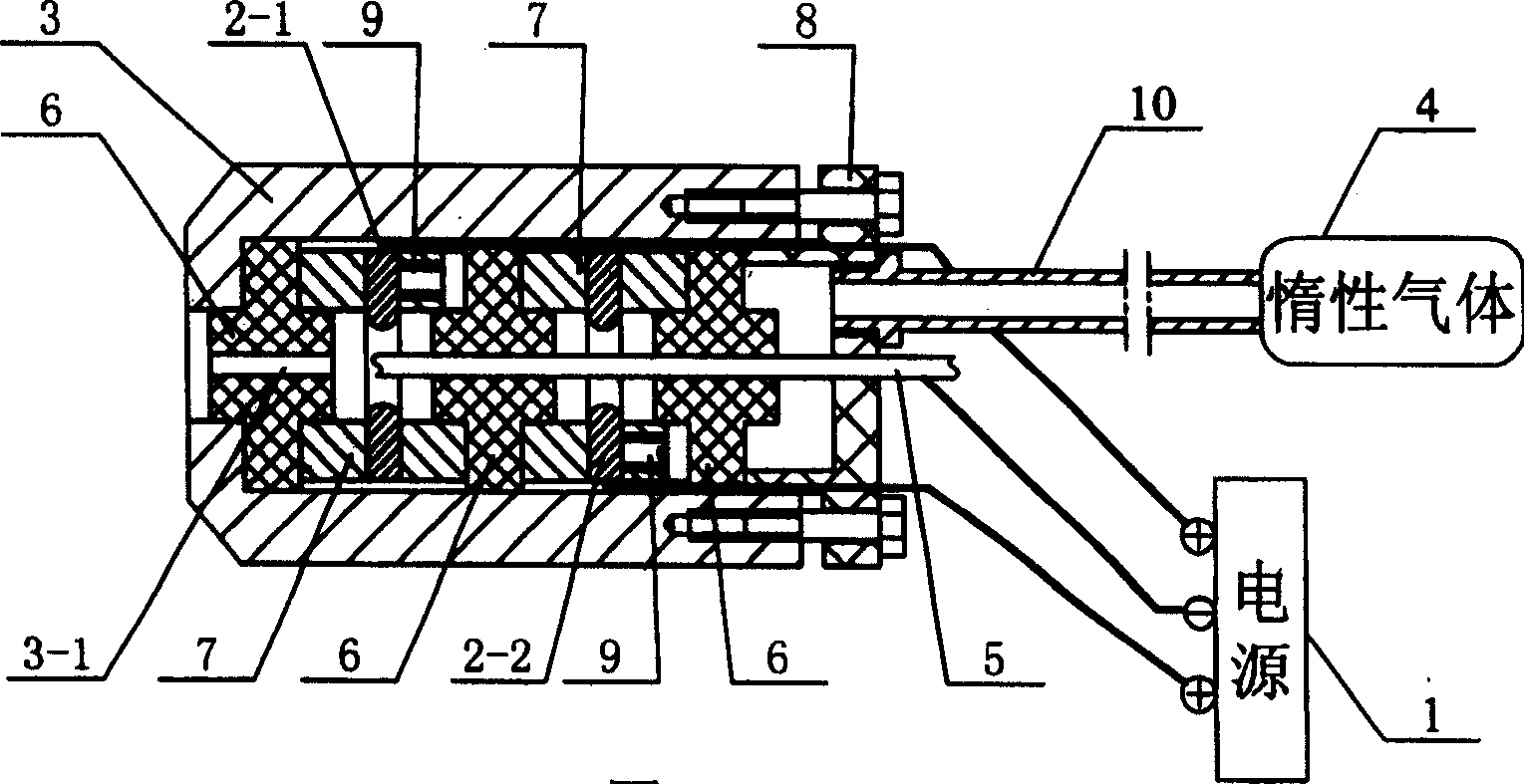

[0006] Specific implementation mode one: the following combination figure 1 and figure 2 This embodiment will be specifically described. It consists of a power supply 1, two tungsten electrodes, a pipeline 10, a shell 3 and an inert gas container 4, and the closed shell 3 has a thread-through hole 3-1, the first tungsten electrode 2-1 and the second tungsten electrode 2-2 is arranged in the inner cavity of the housing 3 and arranged on both sides of the threading hole 3-1, the first tungsten electrode 2-1 and the second tungsten electrode 2-2 are arranged in the axial direction of the threading hole 3-1. Stagger the distance and connect with the anode output end of the power supply 1 respectively, the inner cavity of the housing 3 communicates with the inert gas container 4 through the pipeline 10, and the welding wire to be processed is connected with the cathode of the power supply.

specific Embodiment approach 2

[0007] Specific implementation mode two: the following combination figure 1 This embodiment will be specifically described. The difference between this embodiment and Embodiment 1 is that it also includes three spacers 6, two positioning sleeves 7 and a gland 8, and the spacers 6 and positioning sleeves 7 are sealed in the inner cavity of the housing 3 by the gland 8. Among them, two positioning sleeves 7 separate the three spacers 6, and the first tungsten electrode 2-1 and the second tungsten electrode 2-2 are fixed on the positioning sleeve 7 by screws 9. With such arrangement, it is very convenient to assemble and disassemble the tungsten electrode, which makes the work of adjusting and repairing the tungsten electrode easy.

specific Embodiment approach 3

[0008] Specific implementation mode three: the following combination image 3 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the first tungsten electrode 2-1 and the second tungsten electrode 2-2 can be ring electrodes according to specific needs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com