a wire drawing machine

A wire-pulling machine and wire-pulling technology, which is applied in the direction of insulating conductors/cables, household appliances, electrical components, etc., can solve the problems of inconvenient use and poor wire-pulling effect, and achieve the effect of improving practicability and speeding up cooling and forming speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

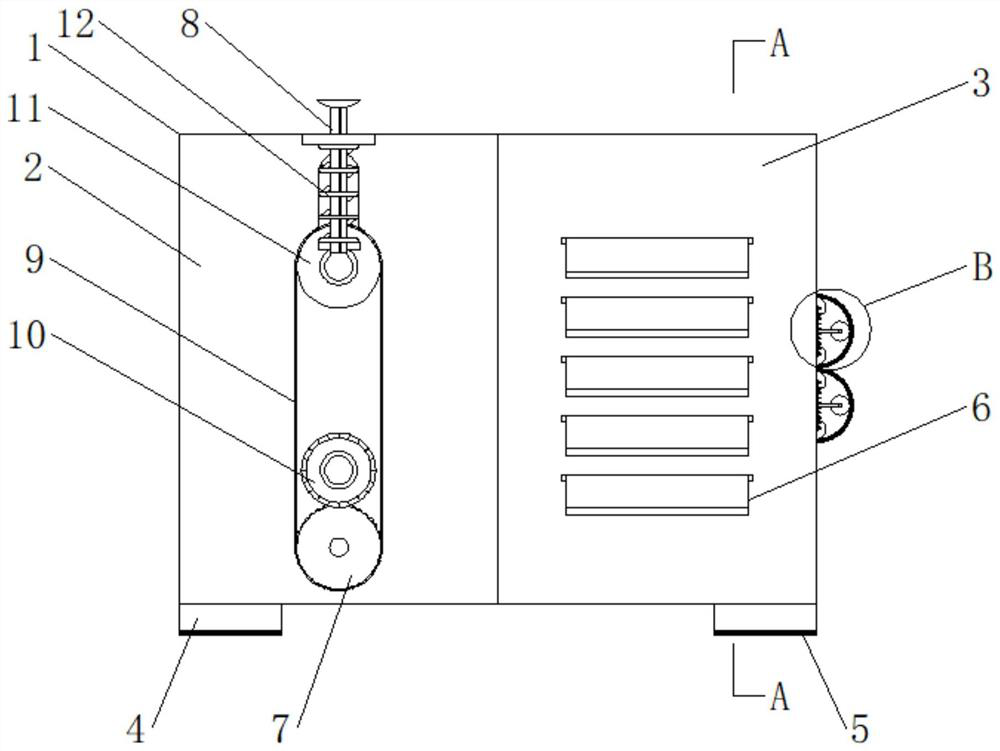

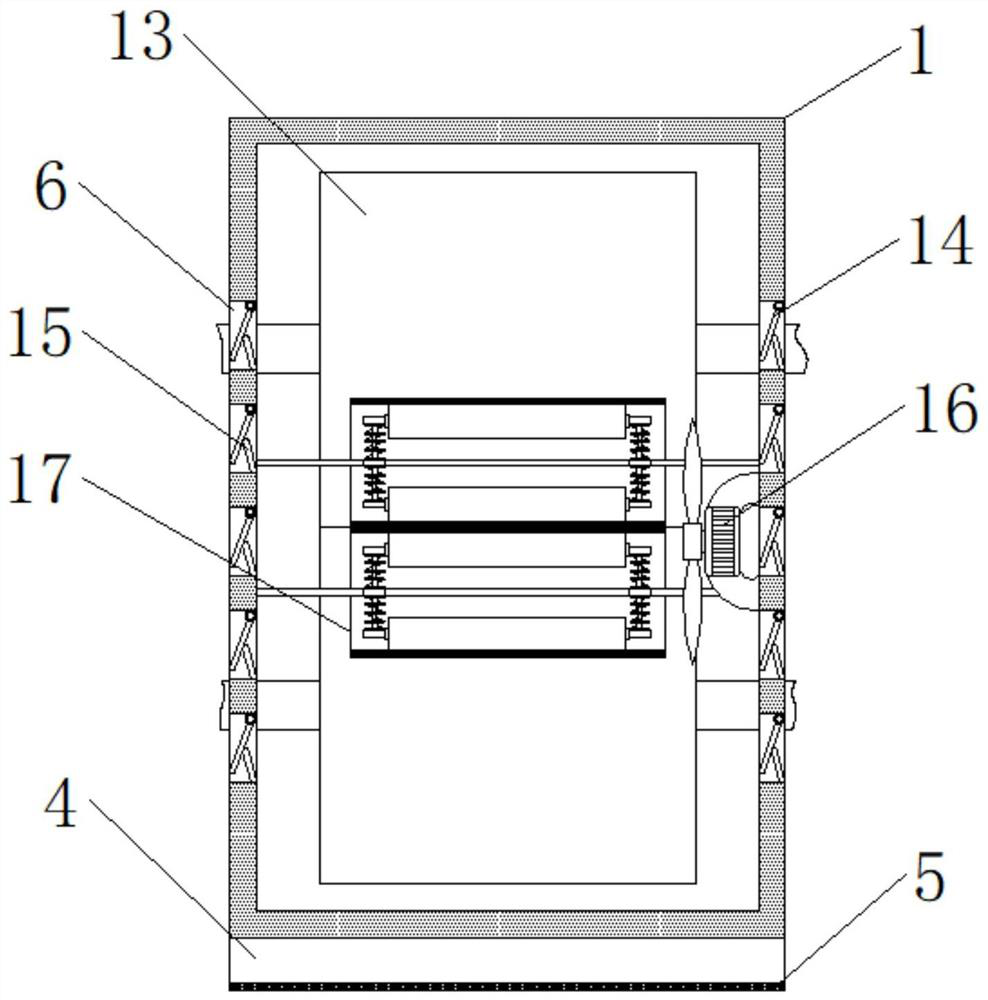

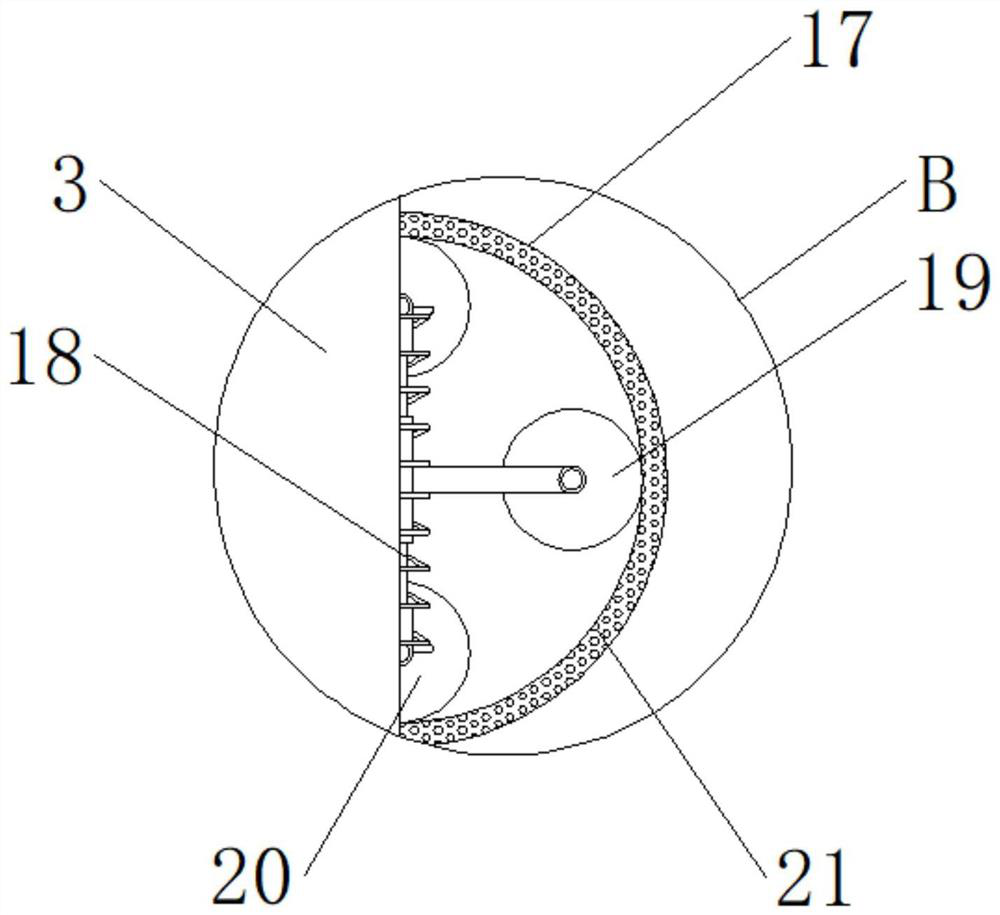

[0021] Example 1, please refer to Figure 1-4 , the present invention provides a technical solution: a wire-drawing machine, comprising a device as a whole 1, a wire-drawing mechanism 2, a cooling part 3 and a supporting leg 4, one side of the device as a whole 1 is fixedly connected with a wire-drawing mechanism 2, and the other side of the device as a whole 1 The cooling part 3 is fixedly connected to the side, the support legs 4 are fixedly connected to both sides of the bottom end of the whole apparatus 1, the transmission wheel 7 is fixedly connected to the front middle bottom of the pull wire mechanism 2, and the outer periphery of the transmission wheel 7 is nested and connected to a rubber transmission belt 9. The front middle bottom of the cable mechanism 2 is fixedly connected with a driving motor 10, and the front top of the cable mechanism 2 is movably connected with a top transmission wheel 11, and the front middle position of the top transmission wheel 11 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com