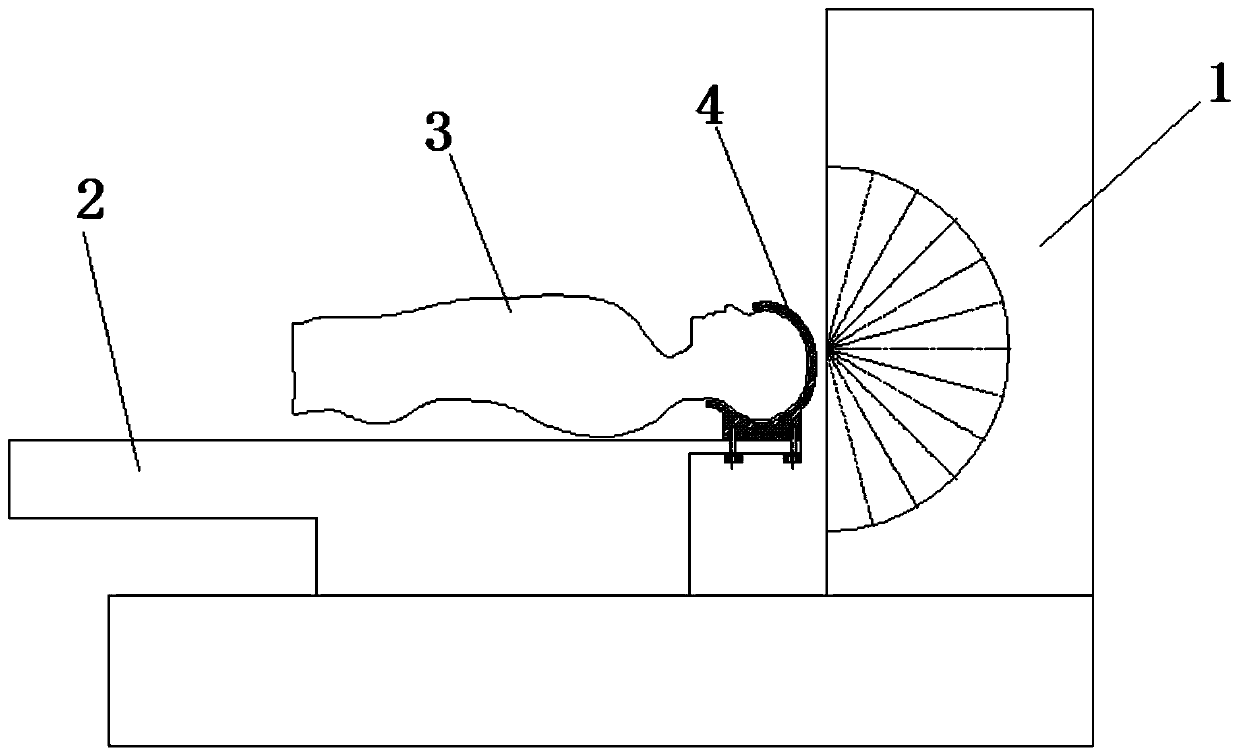

3D-printed head mold for gamma knife surgery and manufacturing method and fixation method thereof

A printing head mold, 3D printing technology, applied in 3D modeling, surgery, operating table, etc., can solve problems such as head nails cannot be removed, patients are uncomfortable, patients have physical trauma and psychological pressure and fear, and achieve positioning accuracy to realize digitalization , Accurate positioning, satisfying the effect of precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

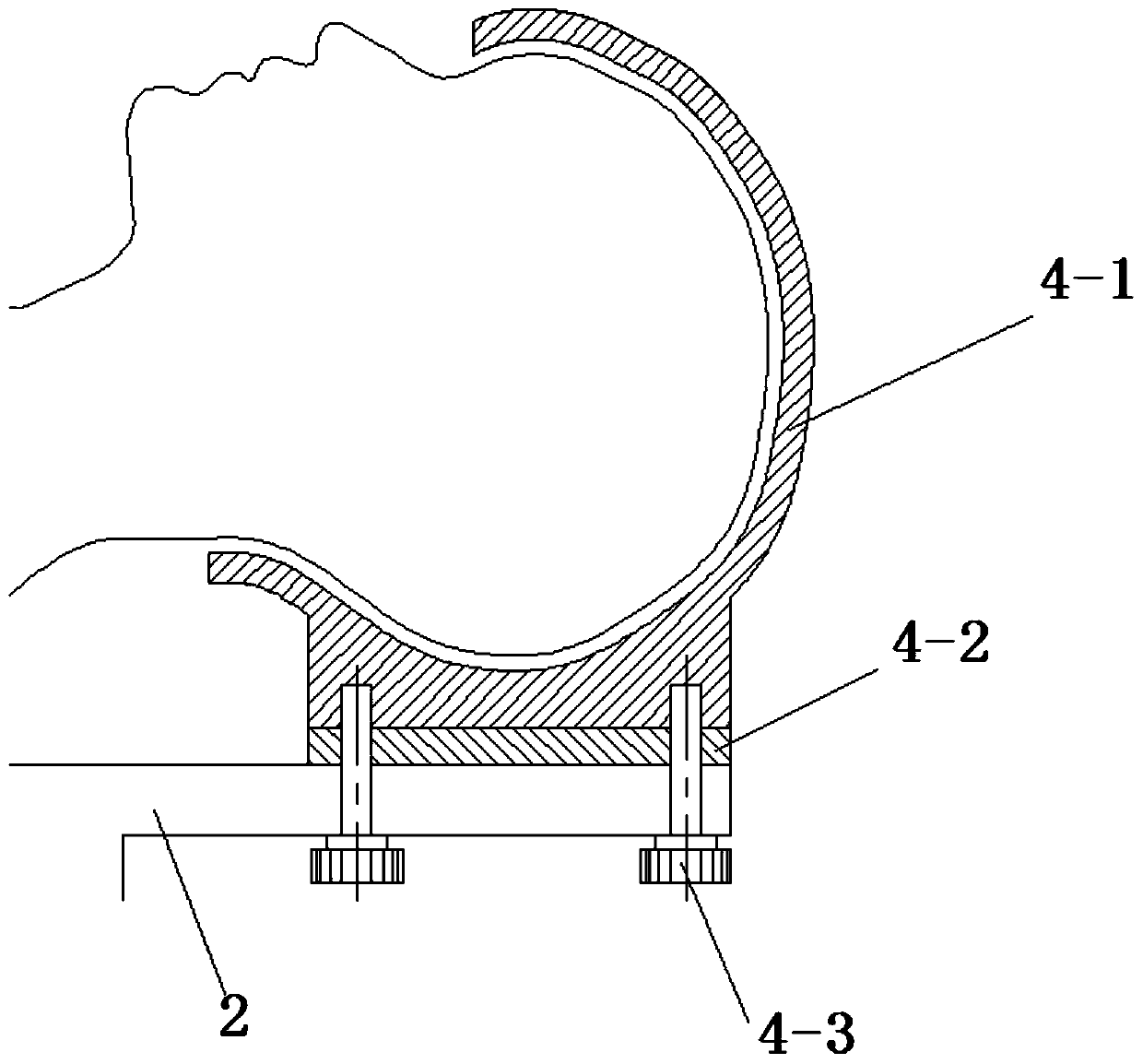

[0029] Such as figure 2 As shown, the 3D printing head mold for gamma knife surgery according to the present invention includes a printing head mold body 4-1 and an adjustment gasket 4-2.

[0030] The inner surface of the printing head mold body 4-1 can fit the patient's head. The part of the printing head mold body 4-1 opposite to the occipital bone of the patient's skull is the bottom. When in use, the bottom of the printing head mold body 4-1 is placed on the adjustment pad On the sheet 4-2, the print head mold body 4-1 and the adjusting gasket 4-2 are fixed on the operating bed 2 together. The adjusting shim 4-2 is provided with a series of shims of different thicknesses, so that the adjusting shims of different thicknesses can be selected according to needs, so that the patient's head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com